Type Grinding Metallurgy

2020-02-26T01:02:19+00:00

Powder metallurgy – basics applications

Grinding: Different types of grinding equipments/methods are shown in the figure Jaw crusher Gyratory crusher Roll crusher Ball Mill Vibratory Ball Mill Attritor2 天前 Grinding mills reduce particle size by impact, rolling and sliding Of the many types in use, the cylindrical mill, which employs a cascading mass of balls or rods, is universally used for the size reduction of hard, moderate to highly abrasive materials, Grinding Mills 911 Metallurgist material type and the microstructural features under investigation Principles used in standard metallographic preparation are applicable This involves rough grinding using coarse grit papers and progressively using finer grit paper before polishing stages as shown in Table 1 Application of interstage etching during final polishingField Metallography By: Dr E Mogire

Grinding and Polishing Guide

The grinding abrasives commonly used in materials preparation are silicon carbide (SiC), aluminum oxide (Al2O3), emery (Al2O3 Fe3O4), composite ceramics and diamond Emery paper is rarely used today in materials preparation due to its low cutting 81 Grinding 811 Grinding action Industrial grinding machines used in the mineral processing industries are mostly of the tumbling mill type These mills exist in a variety of types rod, ball, pebble autogenous and semiautogenous The grinding action is induced by relative motion between the particles of media the rods, balls or pebbles TECHNICAL NOTES 8 GRINDING R P King Physical Metallurgy Lab 20152016 Instructor Depending on the type of failure, it may be necessary to take several specimens from the area of failure and from adjacent areas Grinding is a most important operation in specimen preparation During grinding, the Physical Metallurgy Lab IIT K

Metallic grain structures and microscopic analysis

The grinding and polishing process flow for a mirror is as follows: Initial coarse grinding is performed on the surface The surface is gently polished with fine to very fine abrasives until nearly all damaged areas are removed, typically using diamond, aluminum oxide or colloidal silicon dioxide on appropriate polishing cloths and discs Tempering of inductionhardened parts in which maximum wear resistance, or fatigue properties are desired, is not done after inductionhardening Other parts may be tempered to required hardness values If inductionhardened parts are to be given grinding treatment, then tempering may be done at 150°160°C to avoid cracks during grinding 5InductionHardening: Types and Methods Steel Structure developed by the heat treatment of a highchromium iron Specimen from a chute liner 50 mm thick, containing 26% total carbon, 15% Si, 11% Mn, 143% Cr, and 30% Mo, reheated to 1040 to 1065 C and air cooled Structure is M7C3eutectic carbides in a matrix of martensite and fine spheroidized M3C carbidesMetallurgical Aspects of HIGH CHROMIUM WHITE IRONS

metallurgy type, metallurgy type Suppliers and

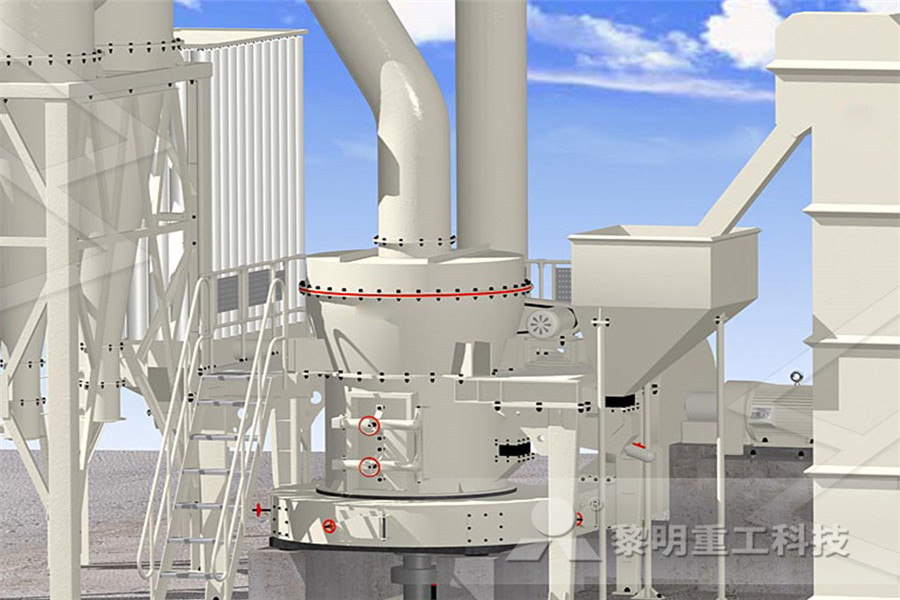

10,526 metallurgy type products are offered for sale by suppliers on Alibaba, of which bridge cranes accounts for 27%, crusher accounts for 4%, and pumps accounts for 2% A wide variety of metallurgy type options are available to you, such as viet nam, india, and australiaThe composites were manufactured by powder metallurgy techniques, in a grinding using a ball mill spex type (high energy) at a ratio of balls/ powders of 10:1 and grinding time of 30 and 60 minutes using stearic acid (C18H36O2) as Get pricegrinding of aluminium metallurgy Powder metallurgy – basics applications Powder metallurgy – science of producing metal powders and making finished mesh belt furnaces (up to 1200C), walking beam, pusher type furnace, batch type furnaces are also used Protective atmosphere: Nitrogen (widely used) R Ganesh Narayanan, IITG The grinding bodies is made of steel or Powder metallurgy – basics applications

Grinding and Polishing Guide

Figure 35 Preparation damage (arrows) in annealed CP titanium (500X, DIC, Kroll's reagent) A Planar grinding machine, like the PlanarMet 300 planar grinding machine shown in Figure 33, utilizes a fixed abrasive stone for rapid sample grinding This type of automated grinder produces planar samples in 12 minutes replacing up to 3 traditional grinding stepsByahut Scientico Offering Grinding Paper, For Metallurgy, GSM: Less than 80 at Rs 125/piece in Jaipur, Rajasthan Read about company Get contact details and address ID: Grinding Paper, For Metallurgy, GSM: Less than 80, Rs All aspects of crushing, ore conveying and screening operation and maintenance: Discuss any type of crushers: gyratory, jaw, cone, roll, HPGR, impact, hammer, etc Crusher liner, lubrication, mantle, bowl, spider and all other componentsOre transportation on conveyor belts and through classification systems such as vibrating screens, grizzlies and feedersMetallurgy Mineral Processing Over 9000

A PROTOCOL FOR CONDUCTING AND ANALYSING

The Southern African Institute of Mining and Metallurgy Platinum 2012 969 C J Greet A PROTOCOL FOR CONDUCTING AND ANALYSING PLANT TRIALS: TESTING OF HIGHCHROME GRINDING MEDIA FOR IMPROVED METALLURGY C J Greet Magotteaux Australia Abstract It is widely accepted that the type of grinding media has an impact on the grinding chemistry The correct grinding mill depends so much upon the particular ore being treated and the product desired, that a mill must have maximum flexibility in length, type of grinding medium, type of discharge, and speed With the BallRod Mill it is possible to build this unit in exact accordance with your requirements, as illustratedBall Mills 911 Metallurgist PRODUCTS Shenyang Heavy General Mining Metallurgy Equipment Co, Ltd (hereinafter referred as SMZ),our products covers mining, metallurgy, power, cement and environmentfriendly area, etc, and we mainly focus on designing and manufacturing equipments used in metallurgy, mining, cement plant, power industry and parts; design and development intelligent manufacturing system of Shenyang Heavy General Mining And Metallurgy

TXG13 DRILL BIT RESHARPENERZhejiang Taixing

This machine is portable, accurate and durable, equipped withdiamond grinding wheel made in Taiwan Designed for grinding powder metallurgy drills, the G13 is capableof sharpening the tip end angle (apex angle),the center flute, andthe back bevelFigure 35 Preparation damage (arrows) in annealed CP titanium (500X, DIC, Kroll's reagent) A Planar grinding machine, like the PlanarMet 300 planar grinding machine shown in Figure 33, utilizes a fixed abrasive stone for rapid sample grinding This type of automated grinder produces planar samples in 12 minutes replacing up to 3 traditional grinding stepsGrinding and Polishing Guide Metallurgy deals with the process of purification of metals and the formation of alloys Copper Flash Smelting Process Principles of Metallurgy: The metallurgical process can be classified as the following: 1 Crushing and grinding: The first process in metallurgy is crushing of ores into a fine powder in a crusher or ball mill This process Metallurgy Definition, Principles Examples

GRINDING PROCESS Donuts

Grinding Process Grinding is a surface finishing operation where very thin layer of material is removed in the form of dust particles Thickness of material removed is in range of 025 to 050 mm Tool used is a abrasive wheel Grinding machine is a power operated machine tool where, the work piece is fed 148 MARCH 2010 VOLUME 110 NONREFEREED PAPER The Journal of The Southern African Institute of Mining and Metallurgy Table I Listing of grinding media ‘SiLibeads’ used in the milling tests SiLi grinding Material Bead size Microhardness Specific weight Symbols for tip speed media type The effect of grinding media J performance on milling Metallurgy Metallography is the fastest growing requirement in industry today Re and case studies show that the product life cycle is often attributable to properties examined at the microscopic levelMicrolab Metallurgy

Thermal Cutting of Metals (With Diagram) Metallurgy

2 天前 After reading this article you will learn about the process of thermal cutting of metals with the help of suitable diagrams Thermal cutting is a family of processes in which heat of an electric arc, radiation energy or an exothermic reaction is utilised to melt or oxidise a Transformationhardened metals react much like solidsolutionhardened metals, assuming they have enough hardenability to form martensite during heat treatment or have formed martensite in previous heat treatments A temperature profile of a transformationhardened metal identifies four basic regions in the HAZ, with heat input determining both the width of the HAZ and the width of each regionMetallurgy Matters: Welding’s effect on strengthened The åtto abrasives KF711 Cork bonded wheel range is suitable for the wet and dry grinding, polishing and centerless grinding of saw blanks, cutlery, turbine blades, as well as medical implants The åtto KF711 range has been specifically designed to offer a flexible bond while maintaining its abrasive properties Using a flexible grinding wheel provides the opportunity to get the job done About åtto Abrasives

Surface hardening metallurgy Britannica

2 天前 Surface hardening, treatment of steel by heat or mechanical means to increase the hardness of the outer surface while the core remains relatively soft The combination of a hard surface and a soft interior is greatly valued in modern engineering because it can withstand very high stress and fatigue, a property that is required in such items as gears and antifriction bearings Cast iron is derived from pig iron, and while it usually refers to gray iron, it also identifies a large group of ferrous alloys which solidify with a eutectic The colour of a fractured surface can be used to identify an alloy White cast iron is named after its white surface when fractured, due to its carbide impurities which allow cracks to pass straight throughCast Iron Metallurgy for Dummies