oversize material feeder roller mill

2021-08-08T14:08:13+00:00

oversize material feeder hammer mill

>> Oversize Material Feeder Hammer Mill Hammer Mill Grinder 911metallurgistthe vertica is a versatile hammer mill for the size reduction of your freeflowing bulk materials designed for particle sizes mm, bulk densities of 02 to 08 kgdm a moisture content 15% and a temperature its an excellent solution for animal feeds, grain, oilseed and Oversize Material Feeder Hammer Mill Creek Oversize Material Feeder Hammer Mill Creek The GD and 2D hammer mills are designed for the animal feed industry to grind raw materials into small particles and meal Both the GD and 2D hammer mill series cover capacities ranging from 5 100 tons per hour dependent on type of raw material formula and required grinding structure and can be oversize materiel feeder hammer mill hrnovakozniczoversize material feeder hammer mill oversize material feeder hammer mill Hammer Mill Grinder 911Metallurgist In an airswept mill, the body of which does not differ significantly in general design from a trunnion overflow mill, a powerful stream of air is passed through the mill and removes the finer particles produced by the grinding processoversize material feeder hammer mill whitebull

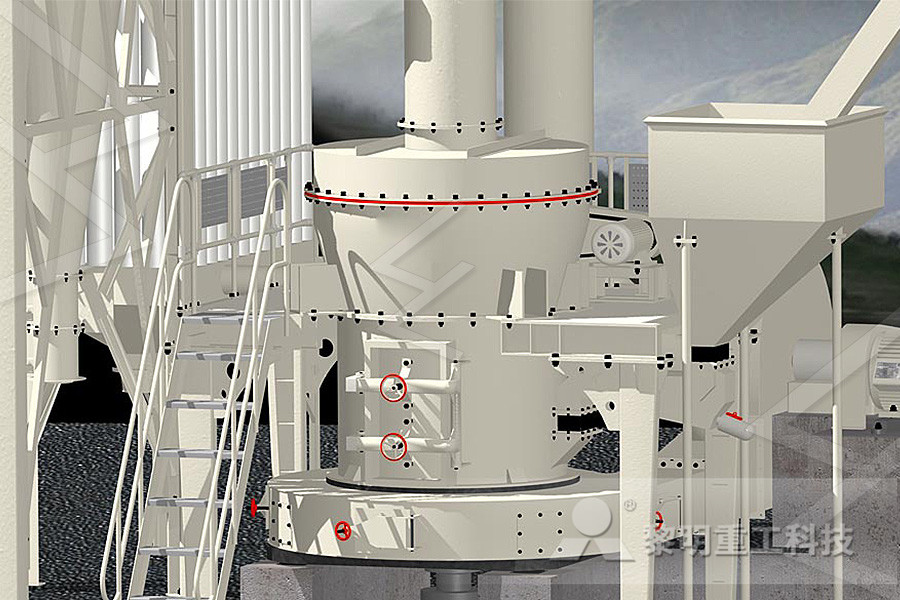

Industrial Roller Mill Roller Mill Manufacturer

The feeder (A) introduces raw material into the grinding chamber in the base of the Roller Mill (B) at a rate determined by pressure variations with the grinding mill Plows located ahead of each roller direct the material upward and between the grinding rolls and the heavy alloy PMCA Rotary Feeder A highcapacity rotary feeder for introducing cement raw materials, principally quarried limestone, into a vertical roller mill (VRM) or other type of raw mill Designed for throughputs from 150 to 1000 tons per hour, the PMCA feeders are built to operate for a 24month cycle between rebuildsPMCA Rotary Feeder Precision Machine and 2 天前 The classifier separates and (1) returns the oversize material to the mill for further grinding, (2) delivers the fine material as finished product of that circuit Material returning to the mill is called circulating load, and the ratio of this material to new feed may vary Grinding Mills 911 Metallurgist

Roller Mill Maintenance00 CPM

roller mill is operated with the rolls out of tram or out of parallel, significant thrust loads may be exerted on the rolls and bearings In machines with straight bore bearings, the forces may be enough to cause the rolls to shift sideways in the machine, even contacting the mill frame Ringroller mill The Lopulco LM 16 is a laboratory scale continuous throughput ringroller mill which has not previously been reported in biomass milling literature The mill is a bespoke oneoff experimental test mill and is around 40 years old, but was fully refurbished before this studyInfluence of mill type on densified biomass Separate the material into two or more fractions • Transport the material to provide the screen its carrying capacity! Oversize Undersize Feed Screen Performance Carrying Capacity the amount of material a screening machine can carry over the decks before the momentum of the screen body is overcome by the weight of the materialPrinciples of Screening and Sizing 911 Metallurgist

Polysius Roller Mills For grinding

uses the testroller mill Atrol (throughput approx 240 kg/h) for grindability testing and quantitative prediction of wear in industrial mills Roller mill for granulated blast furnace slag grinding in China Roller mill for cement raw material grinding in China Roller mill for cement clinker grinding in Mexico Coal grinding plant in PolandOversize dual roller spindle bearings are used in both front and rear of the spindle to provide optimal spindle rigidity that is capable of handling 10mm cutting depth on hard material The GT series is ideal for high productivity turning and milling with exceptional speed, power, and capacityYEONG CHIN MACHINERY INDUSTRIES CO, LTDMaterial from the mill floor is lifted by plows and the continuous flowing airstream and directed between the roller and fixed die ring where it is ground using a combination of attrition and impact When the material is ground to the desired fineness, it is sized and discharged from the mill via air streamAirswept Roller Mills Bradley Pulverizer Company

HEMANT ENGINEERS 3 Roller Grinding Mill

Crude material to be pulverised is fed to the mill from the storage bin through an automatic roll feeder Within the grinding chamber, ploughs set in front of each roller lift and project the material in a continuous stream between the rollers and the pulverizing ring4 ROLLER MILL PLANT Laxmi Engineering 4 ROLLER MILL PLANT Material to be grind is feed to the grinding chamber through feeder The positioning of the ploughs ensures that the material continuously passes between the rotating rollers and the stationary bull ring and as grinding mill for plant material domyrolmexpl2 天前 The classifier separates and (1) returns the oversize material to the mill for further grinding, (2) delivers the fine material as finished product of that circuit Material returning to the mill is called circulating load, and the ratio of this material to new feed may vary from a Grinding Mills 911 Metallurgist

Roller Mill Maintenance00 CPM

roller mill is operated with the rolls out of tram or out of parallel, significant thrust loads may be exerted on the rolls and bearings In machines with straight bore bearings, the forces may be enough to cause the rolls to shift sideways in the machine, even contacting the mill frameLM Vertical Mill integrates crushing, drying, grinding, classifying and conveying together, and it is specialized in processing nonmetallic minerals, pulverized coal and slag Its coverage area is reduced by 50% compared with ball mill, and the energy consumption is saved by 30%40% similarlySmall Material Vibrating Feeder Separate the material into two or more fractions • Transport the material to provide the screen its carrying capacity! Oversize Undersize Feed Screen Performance Carrying Capacity the amount of material a screening machine can carry over the decks before the momentum of the screen body is overcome by the weight of the materialPrinciples of Screening and Sizing 911 Metallurgist

Van de Vries Spice Corp Case History Modern

Feeder Helps Improve Flavoring Production Process In September 2008, the company installed the roller mill, feeder, and other equipment and started up the milling and screening operation “Since then, we’ve nearly doubled our production rates and are achieving usable yields close to eighty per cent,” says Blackman uses the testroller mill Atrol (throughput approx 240 kg/h) for grindability testing and quantitative prediction of wear in industrial mills Roller mill for granulated blast furnace slag grinding in China Roller mill for cement raw material grinding in China Roller mill for cement clinker grinding in Mexico Coal grinding plant in PolandPolysius Roller Mills For grindingOversize dual roller spindle bearings are used in both front and rear of the spindle to provide optimal spindle rigidity that is capable of handling 10mm cutting depth on hard material The GT series is ideal for high productivity turning and milling with exceptional speed, power, and capacityYEONG CHIN MACHINERY INDUSTRIES CO, LTD

Airswept Roller Mills Bradley Pulverizer Company

Material from the mill floor is lifted by plows and the continuous flowing airstream and directed between the roller and fixed die ring where it is ground using a combination of attrition and impact When the material is ground to the desired fineness, it is sized and discharged from the mill via air streamCrude material to be pulverised is fed to the mill from the storage bin through an automatic roll feeder Within the grinding chamber, ploughs set in front of each roller lift and project the material in a continuous stream between the rollers and the pulverizing ringHEMANT ENGINEERS 3 Roller Grinding Mill4 ROLLER MILL PLANT Laxmi Engineering 4 ROLLER MILL PLANT Material to be grind is feed to the grinding chamber through feeder The positioning of the ploughs ensures that the material continuously passes between the rotating rollers and the stationary bull ring and as grinding mill for plant material domyrolmexpl

Grinding Mills 911 Metallurgist

2 天前 The classifier separates and (1) returns the oversize material to the mill for further grinding, (2) delivers the fine material as finished product of that circuit Material returning to the mill is called circulating load, and the ratio of this material to new feed may vary from a roller mill is operated with the rolls out of tram or out of parallel, significant thrust loads may be exerted on the rolls and bearings In machines with straight bore bearings, the forces may be enough to cause the rolls to shift sideways in the machine, even contacting the mill frameRoller Mill Maintenance00 CPMLM Vertical Mill integrates crushing, drying, grinding, classifying and conveying together, and it is specialized in processing nonmetallic minerals, pulverized coal and slag Its coverage area is reduced by 50% compared with ball mill, and the energy consumption is saved by 30%40% similarlySmall Material Vibrating Feeder

Grinding / Crushing / Size Reduction – XOL Automation

XOL Automation is a diversified engineering company serving the industrial and manufacturing sector in the Middle East and North Africa region Whether you are looking to upgrade machines of an existing operation or build a new factory, XOL Automation brings you the latest equipment from the world’s leading brands This equipment, along with our bestofclass engineering practices, will help Ringroller mill The Lopulco LM 16 is a laboratory scale continuous throughput ringroller mill which has not previously been reported in biomass milling literature The mill is a bespoke oneoff experimental test mill and is around 40 years old, but was fully refurbished before this studyInfluence of mill type on densified biomass