rough grinding machine pdf

2023-04-24T14:04:29+00:00

41 Introduction 42 Types of grinding machines 421

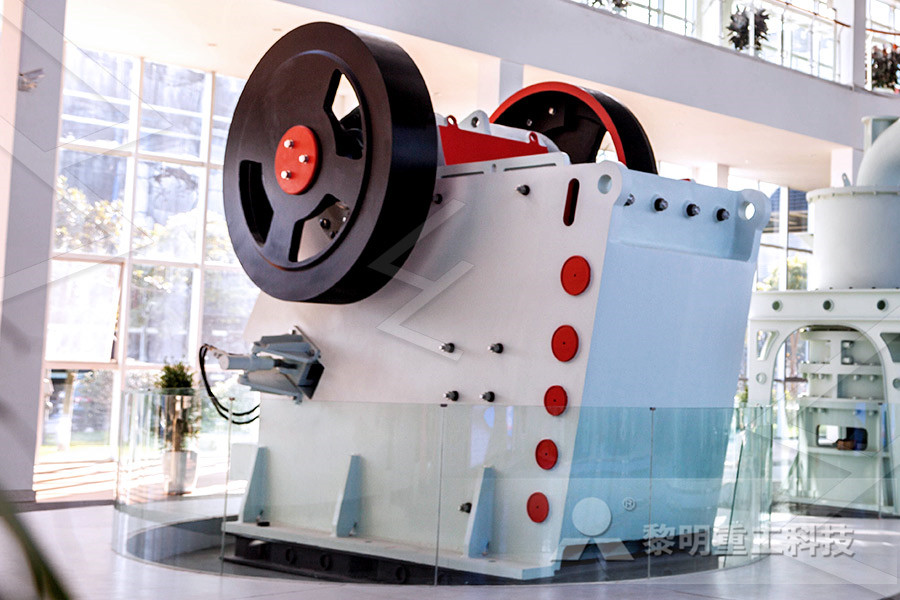

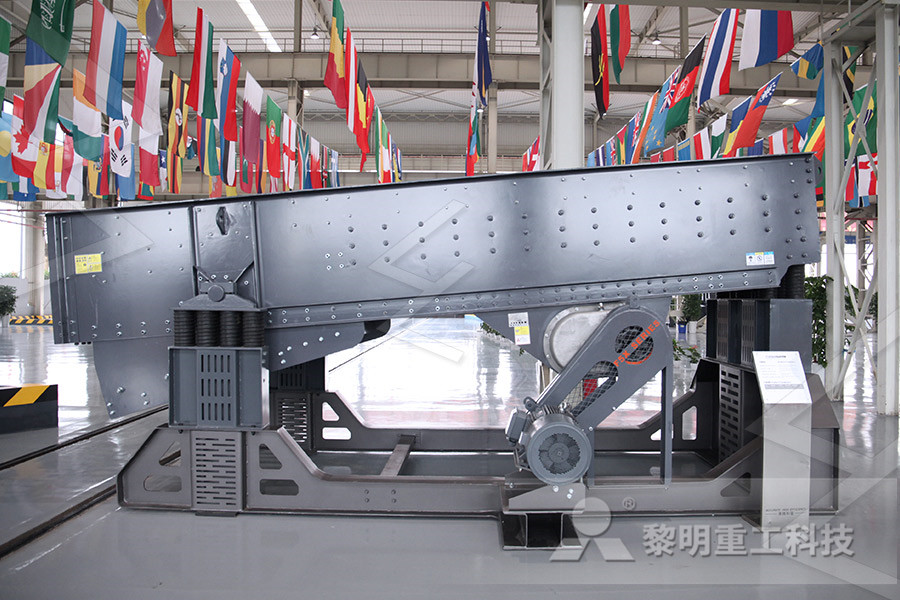

The rough grinding machines are used to remove stock with no reference to the accuracy of results Excess metal present on the cast parts and welded joints are removed by rough grinders The main types of rough grinders are: 1 Hand grinding machine 2 Bench grinding machine 3 Floor stands grinding machine 4 Flexible shaft grinding machine 5 RECIPROCATING SURFACE GRINDING MACHINE for fastening the workpiece to the table This grinding machine has an internal pump and piping network for The reciprocating surface grinding machine is a horizontalautomatic application and recirculation of a coolant to the type surface grinding machine Workpieces are fastened to the workpiece and wheelGRINDING MACHINES Carnegie Mellon University of quality of grinding, it is classified as rough grinding and precision grinding 221 Rough Grinding It involves removal of stock without any reference to the accuracy of results Generally, rough grinding is followed by precision grinding 222 Precision Grinding Precision grinding removes negligible amount of metalUNIT 2 GRINDING Grinding IGNOU

Grinding and Finishing IIT Bombay

grinding energy (u) of 35 Ws/mm3 • The grinding wheel rotates at 3600 rpm, has a diameter (D) of 150 mm, thickness (b) of 25 mm, and (c) 5 grains per mm2 The motor has a power of 2 kW • The work piece moves (v) at 15 m/min The chip thickness ratio (r) is 10 • Determine the grinding force and force per grain • Determine the Grinding and Polishing / 37 Fig 41 Automatic grinding and polishing machine Subroutine 41: Cleaning Ceramographic Mounts After each abrasive step, rinse each specimen in warm tap water Do not remove specimens from the holder if an automatic polishing machine is being used Use distilled or deionized water if the tap water is too hardGrinding and Polishing ASM International on grinding applications The guide covers these main areas: • Technical basics • Three applications • The working environment We begin by explaining some technical terms and the concepts that lie behind them Three applications then form the heart of the guide We look at: • Precision or die grinding • Rough grinding and cutting offPocket Guide to Grinding Technique Atlas Copco

GRINDING WHEEL

Grinding elements should be fastened safely This should be done with fastening flanges as shown in the diagrams below PROTECTIVE GUARDS Grinding elements should be covered by wheel guards on the grinding machine; These guards should be made of a suitable material, depending on the type of machine and use Rough, low grade surface resulting from sand casting, torch Or saw cutting, chipping or rough forging Machine operations are not required because appearance is not objectionable This surface, rarely specified is suitable for unmachined clearance areas on rough construction itemsSurface Texture Machining Symbols utclujro 21: Grinding Grinding can be defined as the rapid removal of material from a sample either to reduce it to a suitable size or to remove large irregularities from the surface The grinding wheel or plate typically rotates at a high speed (around 2001000rpm) and a Lapping and Polishing Basics South Bay Tech

MACHINING OPERATIONS AND MACHINE TOOLS

– A machine operation in which a work part is fed past a rotating cylindrical tool with multiple edges (milling machine) • Types – Peripheral milling • Slab, slotting, side and straddle milling • Up Milling (Conventional) down milling (Climb) – Facing milling • Conventional face, Partial face, End, Profile, Pocket contour of quality of grinding, it is classified as rough grinding and precision grinding 221 Rough Grinding It involves removal of stock without any reference to the accuracy of results Generally, rough grinding is followed by precision grinding 222 Precision Grinding Precision grinding removes negligible amount of metalUNIT 2 GRINDING Grinding IGNOU finishing grinding Rough grinding of excess weld metal on the foot, web and head of rails takes approx 20 minutes, and finishing grinding of surface irregularities of a rail approx 40 minutes per meter of rail We decided to develop a machine for rough grinding work that involves a large amount of grinding and demands muchDevelopment of a Rail Grinding Machine for Welds

Use of rough grinding machines for abrasive cutting

These keywords were added by machine and not by the authors This process is experimental and the keywords may be updated as the learning algorithm improves Élektostal' Plant on grinding applications The guide covers these main areas: • Technical basics • Three applications • The working environment We begin by explaining some technical terms and the concepts that lie behind them Three applications then form the heart of the guide We look at: • Precision or die grinding • Rough grinding and cutting offPocket Guide to Grinding Technique Atlas Copco Grinding elements should be fastened safely This should be done with fastening flanges as shown in the diagrams below PROTECTIVE GUARDS Grinding elements should be covered by wheel guards on the grinding machine; These guards should be made of a suitable material, depending on the type of machine and useGRINDING WHEEL

Grinding Machine: Types, Parts, Working

Working principle of Grinding Machine: The working principle of a grinding machine is quite easier to understand In a grinding machine, there is an electric motor which supplies the motion power to the grinding wheel with the help of a belt and pulley So when we start the electric motor the motor rotates at a certain rpm (15015000 RPM, it may change according to the types of grinding This is a small grinder operated with electric power It can be easily carried anywhere Grinding can be done by holding it in hand It is used for cleaning the heavy welding jobs On one end of the motor shaft, a grinding wheel is fitted and on the other end, a handle or switch for operating the machine is fixed according to our convenience14 Types of Grinding Machines [Working, Diagram REMA double grinding machines offer various machine versions to meet the special requirements of our customers Portfolio: bench grinders, combined grindingpolishing machines, rough grinding machines, steel and pipe grinding machinesREMA grinding machines for metalworking and industry

Surface Texture Machining Symbols utclujro

Rough, low grade surface resulting from sand casting, torch Or saw cutting, chipping or rough forging Machine operations are not required because appearance is not objectionable This surface, rarely specified is suitable for unmachined clearance areas on rough construction itemsRough, intermediate and finish grinding in a single pass: Using the throughfeed grinding method, the JUPITER 500 replaces the rough and intermediate grinding processes by using a special CBN grinding wheel set This saves the user the need to perform several work JUPITER Grinding machine: JUNKER Group RECIPROCATING SURFACE GRINDING MACHINE for fastening the workpiece to the table This grinding machine has an internal pump and piping network for The reciprocating surface grinding machine is a horizontalautomatic application and recirculation of a coolant to the type surface grinding machine Workpieces are fastened to the workpiece and wheelGRINDING MACHINES Carnegie Mellon University

THE VISION OF PRECISION Optical Grinders

HighQuality Grinding that Exceeds Specifications—The accuracy of our grinding and processing work goes beyond simply measuring RZ to deliver markless and sharpedge mirror finishes Reliable, HighRigidity Structure—The processes—rough, semifinish, and finish form of the machine has been developed by advanced threedimensional design and on grinding applications The guide covers these main areas: • Technical basics • Three applications • The working environment We begin by explaining some technical terms and the concepts that lie behind them Three applications then form the heart of the guide We look at: • Precision or die grinding • Rough grinding and cutting offPocket Guide to Grinding Technique Atlas Copco Grinding and machine tool machining are separated by a gap in technological knowledge This project investigated the gap between the two areas in a functional Basic grinding involves a hard rough surface passing over a softer material, and removing parts of the softer Figure 11 – Basic motion of a planar grinding machine 2 material COST BASIS OF GRINDING MACHINE VS MACHINING

GRINDING WHEEL

Grinding elements should be fastened safely This should be done with fastening flanges as shown in the diagrams below PROTECTIVE GUARDS Grinding elements should be covered by wheel guards on the grinding machine; These guards should be made of a suitable material, depending on the type of machine and useGRINDING ROUGH WORK • Do not use a cuttingoff wheel for snagging • Do not work with the side of a wheel, the grinding or cuttingoff wheel on the machine, ensure that the operating speed of the machine does not exceed the maximum operating speed as it is marked on the product WHEELNI Cat Export2016 10TechnicalAB Norton Abrasives This grinding machine is capable of heavy cuts and high metalremoval rates Vertical spindle machines use cup, cylinder, or segmented wheels Many are equipped with multiple spindles to successively rough, semifinish, and finish large castings, forgings, and Chapter 17: Grinding Methods and Machines Cutting Tool

MACHINING OPERATIONS AND MACHINE TOOLS

– A machine operation in which a work part is fed past a rotating cylindrical tool with multiple edges (milling machine) • Types – Peripheral milling • Slab, slotting, side and straddle milling • Up Milling (Conventional) down milling (Climb) – Facing milling • Conventional face, Partial face, End, Profile, Pocket contour Rough, low grade surface resulting from sand casting, torch Or saw cutting, chipping or rough forging Machine operations are not required because appearance is not objectionable This surface, rarely specified is suitable for unmachined clearance areas on rough construction itemsSurface Texture Machining Symbols utclujro A wide range of machine chuck dimensions from 1200x500mm to 3000x800mm Suited for all types of grinding, spindle is a cartridge type, sealed and lubricated for life with impeller ventilating heat away from the motor Gravityfeed automatic lubrication system for way surfacesSurface Grinder Machine Tool Division Okamoto