raw mill in dg cement

2019-04-24T09:04:46+00:00

DG Cement

Raw Mill Coal Mill Kiln Cement Mill Pack House ; DGK 1125 tph ; 490 tph ; 50 tph ; 6700 tpd ; 552 tph ; 960 tph (8x120) KHP 1500 tph ; 500 tph ; 52 tph ; 6700 tpd ; 350 tph ; 600 tph (6x100) HUB 1350 tph ; 654 tph ; 66 tph ; 9000 tpd Click to view differet photographs of DG Cement Plants and Office See More Cement Mills, Coal Mill and Raw Mills are from Loesche GMBH of Germeny and Packing Plant is from Haver Boecker of Germeny This Plant would be a great addition to our fleet and landmark of Pakistan Cement Industry See More GroupDG CementRaw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plantIn the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished cement by cement millRaw Mill, Cement Raw Mill, Raw Mill In Cement Plant

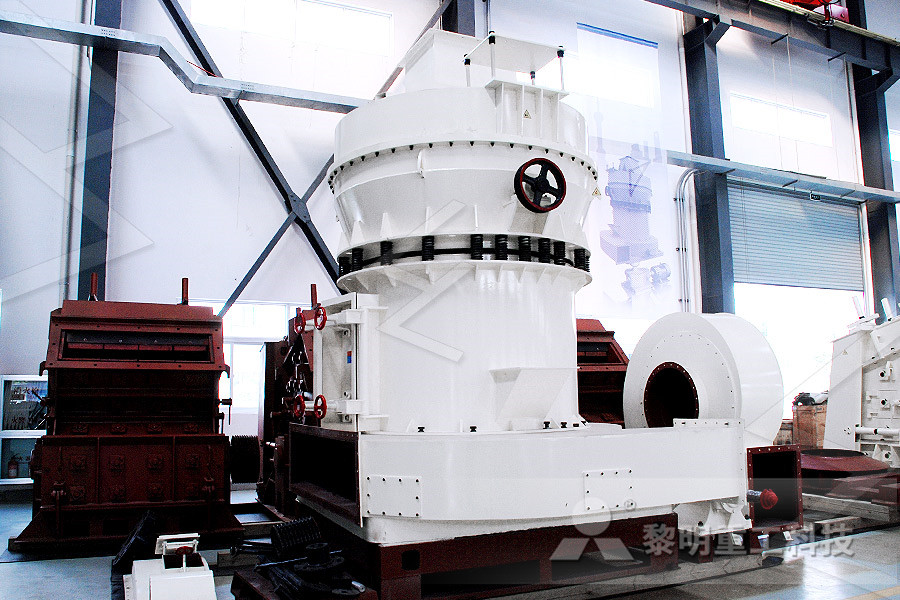

Cement Raw Mill in Cement Plant for Cement Raw Meal

Raw mill is also called cement raw mill, similar to cement ball mill, it is an important cement milling equipment used in the cement production process Raw mill is mainly used for grinding cement raw meal in the cement factory production process It is also suitable for metallurgical, chemical, electric power and other industrial mining enterprises to grind various ores and other grindable A wide variety of raw mill cement options are available to you, such as 1 year, more than 5 years You China Raw Mill Cement, China Raw Mill Cement 13 行 Raw Mill Is Widely Used In Cement Plant Raw mill is the key equipment for secondary Raw Mill,Raw Mill In Cement Plant hotcrusher

Vertical Raw Mill for Cement Raw Meal Grinding in Cement

Vertical raw mill is important equipment widely used in the cement raw meal (cement raw materials) grinding section of the cement production process in cement plantBecause the vertical raw mill is the use of roller grinding principle to crush materials, its vertical raw mill operation is more efficient and energysaving, product output is more stable, so in cement industry, electric power In "DGKCC" Dry process is usedThere are three sections of Raw Mill 2Bottom scrapper Separator RAW MILL STORAGE (CF Silo):After Raw mill, the ground materials composition is checked again and then it is stored in CF silo a Storage which provides constant feed of material to Preheater DG Cement is the only cement producing company which (PDF) DG Cement Internship Report Fakhar Sipra The cement raw material mixtures are ground, dried, and classified in the Pfeiffer vertical roller mill For drying the material, hot gases are directed into the mill Product fineness can be adjusted within a wide range (0063 to 02 mm)Raw mills for all requirements Gebr Pfeiffer

Thermodynamic Performance Analysis of a Raw Mill System

The thermodynamic properties of material flows in the raw mill system for cement production were determined using EES software The EES code was also employed to investigate the performance of the raw mill system and its parts The heat loss rate from the raw mill system into the ambient environment was calculated to be 14,414285 MW The The raw mill, with 1050tph nominal capacity, will be the biggest raw material mill in the world, Loesche highlighted “With this project, DG Khan Cement Company has become a trendsetter being the first cement plant establishing a single solution for the grinding of raw material and cement with vertical roller mills equipped with the Loesche updates on DG Khan grinding orders, Pakistan • DG Cement is getting their supply of raw materials from quarries (limestone mountains) • located 78 Km upward from plant site • Nearly 10,000 Tons of raw material is transferred from quarries to plant site daily • VMS is present in which day to day electronic receipts are genereated • bills are paid annually to government supply chain analysis of dg cement SlideShare

DG Khan Cement wellpositioned International

At the end of 2017, DG Khan Cement had 42Mta of production capacity, which represented nine per cent of the domestic production The company is now the thirdlargest cement producer in the country with the secondlargest market share DG Khan has two cement plants located at Dera Ghazi Khan and one at Khairpur District, Chakwal Thus, the contract comprises one raw material mill for 654 t/h raw meal with a COPE drive, one cement mill for 445 t/h OPC with a COPE drive as well as a coal mill for 66 t/h The raw mill with DG Khan opted for pathbreaking grinding technology Technically, a cement producer can have almost complete control over clinker composition by blending raw materials of different compositions to produce the desired result In practice, however, clinker composition is largely determined by the compositions of the locallyavailable raw materials which make up the bulk of the raw mealRaw materials Understanding Cement

DETAILED ENERGY AUDIT AND CONSERVATION IN A

Figure 31: Typical Mimic sample of the Raw Mill Section 4 ENERGY SCENARIO 41 Electrical Energy System The cement plant receives electricity supply from the Captive Power Plant (CPP) (12 MW) and DG sets It is distributed to various sections of the plant An energy meter is installed on 110 kV feeder incomer, which recordsI did internship at DG CEMENT FACTORY KALLAR KAHAR for 1 month (July 2013Aug 2013) I have learned composition procedure of cement manufacturing through Crusher, Raw mill, Kiln, Cement mill Packing Plant I visited Suzuki motors (Ltd) Chakwal We design the Airborne wind turbine on ProE 40 and analyze its operation mechanism on Ansys Abdul Wahid INTERNEE at DG CEMENT FACTORY Raw Mill Clinker Cement Coal 0 Many years of successful cooperation with Sinoma International Engineering ensured that the contract was again awarded to LOESCHE DG Khan Cement Company Limited (DGKCC) was established as private limited company under the management control of State Cement Corporation of Pakistan Limited (SCCP) in 1Clinker Loesche

Malikumair javed QCX Shift Lab Chemist DG Khan

1 Raw material samples 2 Daily crushed Limestone 3 Daily crushed ClayShale 4 Raw Mill output 5 Kiln feed 6 Clinker 7 Cement *Prepare the laboratory reagents and standardize *Handling Monitor Re calibration of XRF XRD *Raw Mill Control by QCX OLX blend expert *Determination of Free Lime by Cubix Pro XRDPHYSICAL LOCATION Abdul Hameed Enterprises Plot No 49D, Formanites Housing Scheme, Kamahan Road, Lahore, Punjab, Pakistan : Phone: Abdul Hameed Enterprises Ceweld Cement Mill 150 tph DG Set 64 MW Capacity Enhancement Raw Mill 220 – 280 tph Kiln 2,500 – 3,750 tpd Salient Features • Installation of SemiMobile Crusher and Limestone Preblending stockpile • Upgradation of Raw Mill by replacing Conventional Rotary Classifier with HighMODERNIZATION AND EXPANSION PROJECT Holtec

cement mill, cement mill Suppliers and Manufacturers

A wide variety of cement mill options are available to you, such as pakistan, none, and turkey You can also choose from building material shops, energy mining, and manufacturing plant cement mill, as well as from 1 year, 2 years cement mill, and whether cement mill is ball mill, or raymond millI did internship at DG CEMENT FACTORY KALLAR KAHAR for 1 month (July 2013Aug 2013) I have learned composition procedure of cement manufacturing through Crusher, Raw mill, Kiln, Cement mill Packing Plant I visited Suzuki motors (Ltd) Chakwal We design the Airborne wind turbine on ProE 40 and analyze its operation mechanism on Ansys Abdul Wahid INTERNEE at DG CEMENT FACTORY Global Cement recently visited the Khairpur cement plant of DG Khan Cement Company, situated at Chakwal in a rural area in Punjab State, northern Pakistan, between Lahore and Islamabad Despite the remote location, the cement plant is a model of modernity, demonstrating admirable selfsufficiency in a number of areas and boasting many DG Khan Khairpur: The ‘selfsufficient’ cement plant

Top Cement Ready mix Concrete Company In India

KILN RAW MILL 1 PC RAW MILL 2 Ba Filter Bag Filter ESP Ba Filter Bag Filter Ba Filter Ba Filter ESP Ba Filter PCEs 1 2 COOLER COAL MILL 1 COAL MILL 2 CEMENT MILL CEMENT MILL CEMENT MILL CEMENT MILL DG3 DG4 DG5 1 1 2 2 NAAQ STD 100 60 80 80 SDShut down, NR Not running B Ambient Air uali Pollutants PMIO g/m3 PM25 /m3 KILN RAW 1 PC RAW MILL 2 Bag Filter Bag Filter Ba Filter Bag Filter COOLER COAL MILL 1 COAC MILL 2 CEMENT CEMENT MILL CEMENT MILL CEMENT MILL DG5 1 1 2 2 Ba Filter 1 Filter 2 Filter Ambient Air Quality ( Monthly Average) LOCATION SDShut dovvn, NR Not runnine B Ambient Air Quality — Pollutants STD PM 10 PM2 5 (pg/m3)6 Nuvoco Vistas Corp Ltd1 Raw material samples 2 Daily crushed Limestone 3 Daily crushed ClayShale 4 Raw Mill output 5 Kiln feed 6 Clinker 7 Cement *Prepare the laboratory reagents and standardize *Handling Monitor Re calibration of XRF XRD *Raw Mill Control by QCX OLX blend expert *Determination of Free Lime by Cubix Pro XRDMalikumair javed QCX Shift Lab Chemist DG Khan

Cement Manufacturing Process Phases Flow Chart

Cement Manufacturing Process Phase 1: Raw Material Extraction Cement uses raw materials that cover calcium, silicon, iron and aluminum Such raw materials are limestone, clay and sand Limestone is for calcium It is combined with much smaller proportions of sand and clay Sand clay fulfill the need of silicon, iron and aluminumChettinad cement is operating its cement business spanning three generations Since its establishment in 1962 with a wet process cement plant at Puliyur near Karur, Chettinad cement has been expanding and making itself versatile in the field of cement productsChettinad cement Chettinad Group of CompaniesPHYSICAL LOCATION Abdul Hameed Enterprises Plot No 49D, Formanites Housing Scheme, Kamahan Road, Lahore, Punjab, Pakistan : Phone: Abdul Hameed Enterprises Ceweld