Grinding Process Design

2020-02-01T23:02:48+00:00

GRINDING PROCESS Donuts

Grinding Process Grinding is a surface finishing operation where very thin layer of material is removed in the form of dust particles Thickness of material removed is in range of 025 to 050 mm Tool used is a abrasive wheel Grinding machine is a power operated machine tool where, the work piece is fed All rights reserved 297 Process design in grinding of advanced ceramics HG Wobker, HK Tonshoff, F Kroos, Institute of Production Engineering and Machine Tools, University of Hannover, FRG Advanced structural ceramics, such as silicon nitride or alumina, are attractive for many advanced applications due to their high strength at elevated temperatures, wear resistance and chemical stabilityProcess design in grinding of advanced ceramics The present chapter will be devoted to a study of the process of grinding within a real mill Since within a “tumbling” type of mill the size reduction can result from direct crushing, from shearing or abrasion between the particles in the feed, between the particles in the feed and the mill bodies or between the particles and the mill liningGrinding Process 911 Metallurgist

Introduction to Modern Grinding Process Technology

Introduction to Modern Grinding Process Technology,Firstrate Mold Solution Co Ltd is based in China and engaged in supply of industrial design, mold design, molding analysis and project management serviceBased the theory of screw grinding and forming grinding wheel dress technology, the relationship between machine working parameters, grinding wheel dressing parameters and screw rotor grinded process parameters are investigated, and the relationship between grinding wheel dressing parameters and the screw rotor grinded process parameters is established, and its formulas are Precision Grinding Process Design of TwinScrew Gear grinding process: machine ergonomics and design October 26, 2017 When developing the G 160 gear grinding machine, particular attention has been paid to ergonomics All needs of the machine engineers for operating, setting and servicing the machine were carefully respectedGear grinding process: machine ergonomics and

Process design of the patterning process of profile

In addition, grinding experiments were conducted to validate the process design The results show a high correlation between the calculated and the resulting patterns on the grinding wheel as well as that a ecrease in cutting forces can be achieved by this approach behaviour of grinding machine towards these aspects is very important A typical grinding machine consists of work pieceroll (metal) and grinding wheel (stone) which keep contact interaction during the process The contact vibration problem of such kind of system is studied in this work In order to ensure the finishing theNumerical and Experimental Approach for Roll Grinding Grinding – Ex 11 • You are grinding a steel, which has a specific grinding energy (u) of 35 Ws/mm3 • The grinding wheel rotates at 3600 rpm, has a diameter (D) of 150 mm, thickness (b) of 25 mm, and (c) 5 grains per mm2 The motor has a power of 2 kW • The work piece moves (v) at 15 m/min The chip thickness ratio (r) is 10Grinding and Finishing IIT Bombay

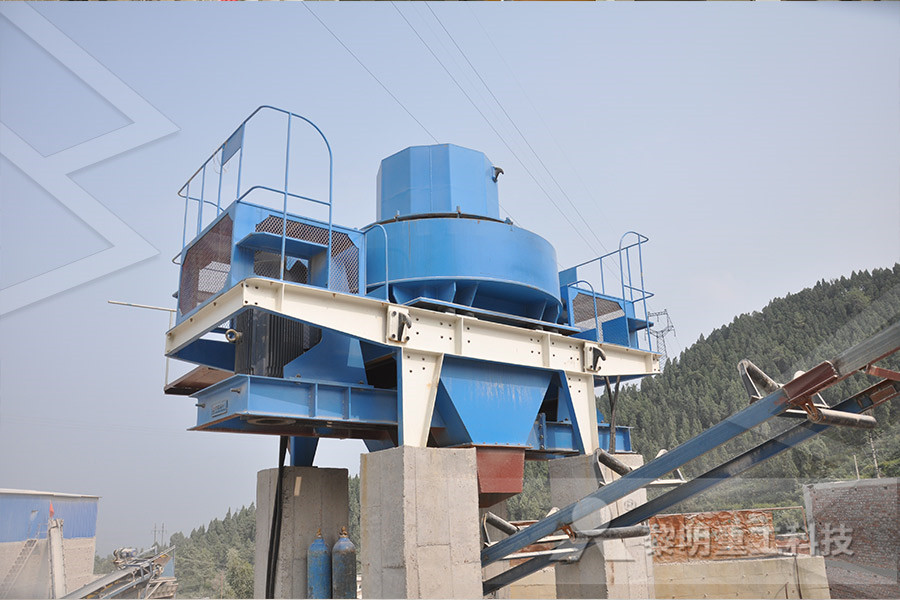

「grinding process design and equipment」

grinding process design and equipment Basics of Grinding ManufacturingThe Grinding Process Grinding is a material removal and surface generation process used to shape and finish components made of metals and other materials The precision and surface finish obtained through grinding can be up to ten times better than with either turning or Let us apply these ideas to the derivation of an equation for the rate of grinding in a mill It follows that if, as appears reasonable, the change of specific surface S cm²/cm³, within a mill depends upon the diameter of the mill, upon the ball diameter and upon the mean diameter of the particle, D, d and b respectively, upon the density of the balls and the pulp, q and σ respectively, on Grinding Process 911 MetallurgistPrecision Grinding Process Design of TwinScrew Compressor Rotor Article Preview Abstract: With the accuracy improvement of twinscrew compressor rotor machining, higher requirement of crew rotor grinded equipment and grinding process is put forward Based the theory of screw grinding and forming grinding wheel dress technology, the Precision Grinding Process Design of TwinScrew

Introduction to Modern Grinding Process Technology

Introduction to Modern Grinding Process Technology,Firstrate Mold Solution Co Ltd is based in China and engaged in supply of industrial design, mold design, molding analysis and project management serviceMirror grinding mainly depends on the precision of the machine tool, cutting and grinding amount and wheel selection and dressing This paper mainly studies the MG1432 highprecision universal cylindrical grinder, exploring the impact on the workpiece roughness through selection and design of various process parameters in grinding, such as changing work table speed in dressing the grinding Mirror Grinding Process Parameter Selection and Whether the process is cylindrical or profile grinding, automation, which can increase cycle time, throughput, consistency of part quality and taking realtime inprocess measurements, is once again in demand The reasons can be found in the benefits found in typical applications and the innovative and effective forms of automation available from machine builders like United Grinding Automating the Grinding Process SME

Grinding and Finishing IIT Bombay

Grinding – Ex 11 • You are grinding a steel, which has a specific grinding energy (u) of 35 Ws/mm3 • The grinding wheel rotates at 3600 rpm, has a diameter (D) of 150 mm, thickness (b) of 25 mm, and (c) 5 grains per mm2 The motor has a power of 2 kW • The work piece moves (v) at 15 m/min The chip thickness ratio (r) is 10Principal Process Design Engineer Grinding / Hard Turning North Canton, OH, US, 44720 Your Career Begins at Timken If you're ready for a challenging career that provides you with the ability to advance personally and professionally, look to Timken Principal Process Design Engineer Grinding / Hard Modern Process Equipment (MPE) provides commercial grinding, grinders for food, chemical and coffee, and custom process mercial Grinding Coffee Process Systems

An Introduction to the Optics Manufacturing Process

the grinding process mechanically removes material by breaking off small pieces of glass, the polishing process is both mechanical and chemical In this stage, the final figure is put into the lens, including its radius of curvature and center thickness There are a variety of methods and materials available for polishing, the most conventional ofgrinding process design and equipment Basics of Grinding ManufacturingThe Grinding Process Grinding is a material removal and surface generation process used to shape and finish components made of metals and other materials The precision and surface finish obtained through grinding can be up to ten times better than with either turning or 「grinding process design and equipment」 Grinding Process Post navigation Previous Next In the previous chapter, with an accuracy sufficient for design purposes The question of the effect of the consistency of the pulp ∅8(U) would appear to be, at least as a first approximation, one which is fairly easily treated However, the published data relating to this variable are in Grinding Process 911 Metallurgist

Introduction to Modern Grinding Process Technology

Introduction to Modern Grinding Process Technology,Firstrate Mold Solution Co Ltd is based in China and engaged in supply of industrial design, mold design, molding analysis and project management service Whether the process is cylindrical or profile grinding, automation, which can increase cycle time, throughput, consistency of part quality and taking realtime inprocess measurements, is once again in demand The reasons can be found in the benefits found in typical applications and the innovative and effective forms of automation available from machine builders like United Grinding Automating the Grinding Process SMEMirror grinding mainly depends on the precision of the machine tool, cutting and grinding amount and wheel selection and dressing This paper mainly studies the MG1432 highprecision universal cylindrical grinder, exploring the impact on the workpiece roughness through selection and design of various process parameters in grinding, such as changing work table speed in dressing the grinding Mirror Grinding Process Parameter Selection and

Numerical and Experimental Approach for Roll Grinding

for Roll Grinding Process Lihong Yuan, VeliMatti Järvenpää, Seppo Virtanen and Hessam K Shiravani Department of Engineering Design Tampere University of Technology POBOX 589, 33101 Tampere, Finland {lihongyuan, velimattijarvenpaa, seppovirtanen, hessamkalbasishirani}@tutfi Abstract The process involves the part being supported on a workpiece rest blade that sits between two rotating cylinders: A regulating wheel, which controls the part’s rotational speed and feed rate (for infeed grinding) or linear travel (for throughfeed grinding) A larger abrasive grinding wheel8 Principles of Centerless Grinding Metal Cutting Principal Process Design Engineer Grinding / Hard Turning North Canton, OH, US, 44720 Your Career Begins at Timken If you're ready for a challenging career that provides you with the ability to advance personally and professionally, look to Timken Principal Process Design Engineer Grinding / Hard

Size Reduction by Grinding as an Important Stage in

breaking, grinding), but all thos e processes usually occur togeth er where one of them is the prevailing process, depending on the mill design Cutting mills with cutters spaced over the drum circumference are widely used for rough and medium grinding of, among others, nonfe rromagnetic light metals, polymer material Modern Process Equipment (MPE) provides commercial grinding, grinders for food, chemical and coffee, and custom process mercial Grinding Coffee Process Systems