kilen springs technical manufacturing

2020-09-16T18:09:41+00:00

Kilen The Spring Specialists

We have over 150 years spring manufacturing experience, and today produce the world's largest range of coils springs for the automotive aftermarket In addition to replacement coil springs, we also stock market leading ranges of Gas, Leaf and Sport springsWelcome to the Kilen Springs technical pages, a guide for distributors, technicians and mechanics Within these pages you will find information on the various types of springs available, including spring design, manufacturing processes and quality control across the Kilen rangeKilen Springs TechnicalKilen Springs Technical Leaf Spring ManufactureKilen Springs Technical Leaf Spring Manufacture

Kilen Springs Technical Gas Spring Manufacture

Gas Spring Manufacturing Gas springs are manufactured from several components The tubes are manufactured from pressure vessel steel with very high demands on inside surface smoothness Piston rods are manufactured from finely ground and polished steel barsCoil Springs Technical Coil springs make up Kilen's most comprehensive product range, and are a vital component within the overall suspension system of a vehicle It is therefore important that distributors, technicians and mechanics are knowledgeable about their design and production Kilen Springs Technical Coil SpringsManufacturing While based on a simple design, manufacturing leaf springs is a multipart process, with variations in the manufacturing methods of parabolic and multileaf springs Quality Ensuring all Kilen leaf springs meet the highest quality standards Kilen Springs Technical Leaf Springs

Kilen – MechanExpert

We have over 150 years spring manufacturing experience, and today produce the world’s largest range of coils springs for the automotive aftermarket In addition to replacement coil springs, we also stock market leading ranges of Gas, Leaf and Sport springs Kilen Technical Guides: Types of Coil SpringCoil Spring Manufacturing Process Whether you have an exist ing spring application in need of reengineering or a new one that requires design in g this guide will help The engineering team and Duer Carolina Coil has been manufacturing springs for well over 100 years and has refined the coil spring manufacturing process for the industry – for all types of coil springsCoil Spring Manufacturing Process: Technical Guide 14纳米FinFET制程如果正式量产,对于中芯国际来说将是一个历史性的时刻。中芯国际首页

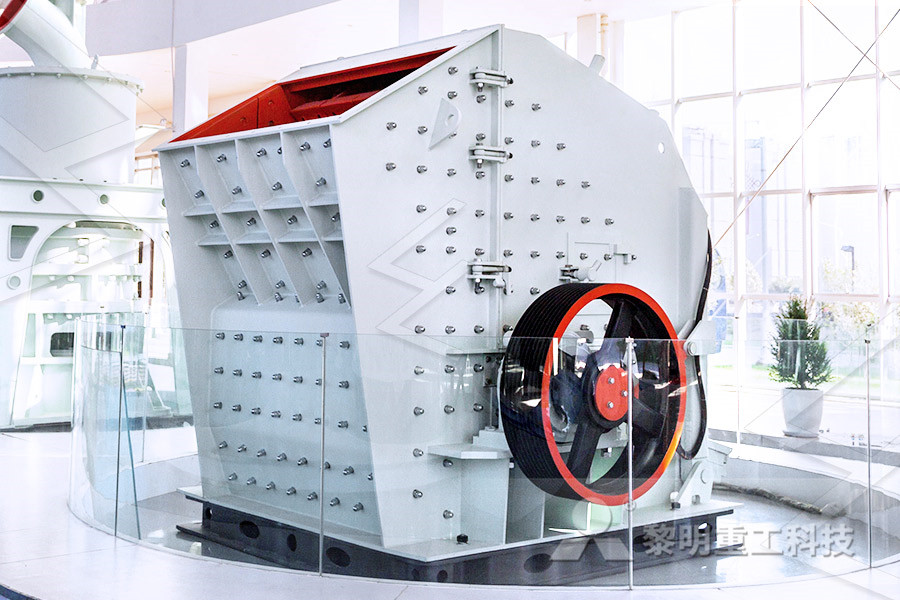

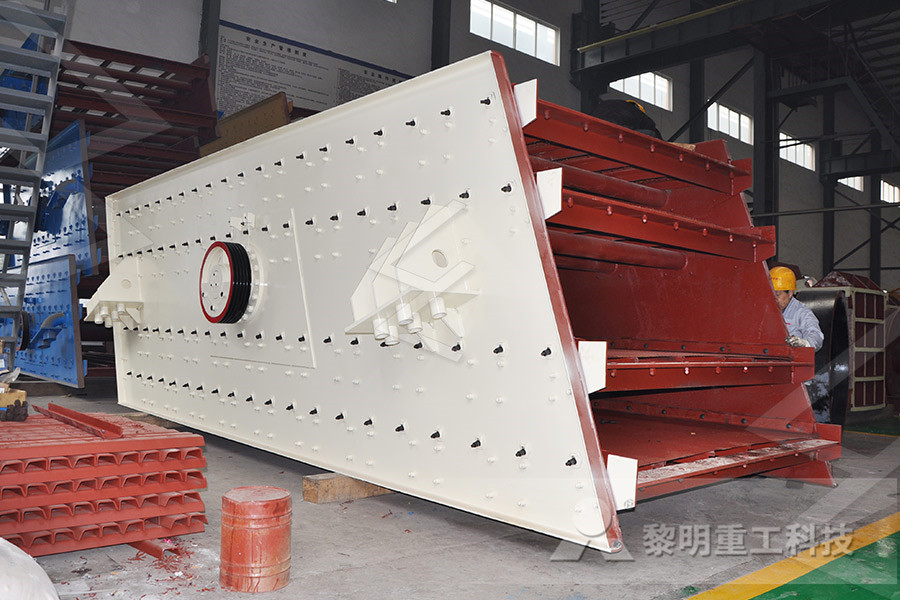

Spring Grinding Machines

Kilen Springs Technical Manufacturing Grinding Some chassis spring designs have one or both ends ground At Kilen this grinding is done in special computer controlled spring grinding machines Shot Peening and Presetting After heat treatment, it is very important to introduce and control the level of positive residual stresses in the material Kilen have over 150 years spring manufacturing experience, and today produce the world's largest range of coils springs for the automotive aftermarket In addition to replacement coil springs, Kilen also stock market leading ranges of Gas, Leaf and Sport springsby Kilen Parts In Motion Kilen from Europe’s leading spring manufacturing group offers the widest range of standard and heavy duty replacement springs in the market Produced in Sweden using cold coiling technology, every Kilen spring undergoes a multistage manufacturing process to ensure optimum performance and the longest possible service lifeCOIL Automeister

SPORT Automeister

SPRINGS SPORT 2016 Kilen from Europe’s leading spring manufacturing group offers the widest range of standard and heavy duty replacement springs in the market Produced in Sweden using cold coiling technology, every Kilen spring undergoes a multistage manufacturing process to ensure optimum performance and the longest possible service lifeKilen is firmly committed to providing the highest quality products, and produces a side load spring design wherever that is used as the original All Kilen springs come with a 3 year warranty and are certified OE ‘Matching Quality’, allowing fitment without warranty restrictions and giving you complete peace of mindSide Load Coil Spring Technology Part InfoSuch springs would be very likely to shorten or sag in use, resulting in the vehicle rideheight dropping This is a problem with some suspension springs, and even if only one of the springs on an axle looks shortened, due to relaxation or sag, it is necessary to replace bothCoil Spring Technology Part Info

Suspension Coil Springs Market Size 2021 Latest In

The Technical Indicator Moog Raw 4x4 Eibach Sogefi Group Neapco Components MW Industries, Inc Ironman 4Ã 4 Kilen Springs 33 Suspension Coil Springs Manufacturing Lesjöfors produce an extensive range of springs for the European Car and Light Commercial Vehicle market, offering highquality products, professional service, and excellent availability Lesjöfors have spent over 160 years manufacturing springs, and today produce the world's largest range of coil springs for the automotive aftermarketLesjöfors Automotive The Complete Automotive EN10021 General technical delivery conditions for steel EN10277 Technical delivery conditions Spring manufacturing DIN 2095 Specifications for cold coiled compression springs DIN 20961 Quality requirements for hot formed springs DIN 20962 Quality requirements for mass production ASTM A125 Steel springs, Helical, Heat treated, Specification forSUSPENSION SPRING QUALITY CERTIFICATE

Original EquipmentStyle Replacement Springs for

ADVANCED DESIGNS FOR NEWER VEHICLES The Monroe spring range includes the latest technology sideload compensation front springs and tapered wire miniblock rear springs for many newer vehicles A leading choice of vehicle manufacturers, sideload compensation front springs feature sophisticated parabolic shapes that help provide optimal vehicle control at all speeds Kilen from Europe’s leading spring manufacturing group offers the widest range of standard and heavy duty replacement springs in the market Produced in Sweden using cold coiling technology, every Kilen spring undergoes a multistage manufacturing process to ensure optimum performance and the longest possible service lifeCOIL Automeister Kilen have over 150 years spring manufacturing experience, and today produce the world's largest range of coils springs We are still open to keep you moving Click to read our COVID19 FAQ Use code 'SAVE5' to get 5% off your entire order PROUD TO BE A UK BASED COMPANY by Kilen Parts In Motion

Side Load Coil Spring Technology Part Info

Kilen is firmly committed to providing the highest quality products, and produces a side load spring design wherever that is used as the original All Kilen springs come with a 3 year warranty and are certified OE ‘Matching Quality’, allowing fitment without warranty restrictions and giving you complete peace of mindSuch springs would be very likely to shorten or sag in use, resulting in the vehicle rideheight dropping This is a problem with some suspension springs, and even if only one of the springs on an axle looks shortened, due to relaxation or sag, it is necessary to replace bothCoil Spring Technology Part Info The Technical Indicator Moog Raw 4x4 Eibach Sogefi Group Neapco Components MW Industries, Inc Ironman 4Ã 4 Kilen Springs 33 Suspension Coil Springs Manufacturing Suspension Coil Springs Market Size 2021 Latest InDepth

SUSPENSION SPRING QUALITY CERTIFICATE

EN10021 General technical delivery conditions for steel EN10277 Technical delivery conditions Spring manufacturing DIN 2095 Specifications for cold coiled compression springs DIN 20961 Quality requirements for hot formed springs DIN 20962 Quality requirements for mass production ASTM A125 Steel springs, Helical, Heat treated, Specification forThe Lesjöfors Group provides the widest range of springs and pressings to customers in diverse industries across the world With a unique expertise in high technological, custommade solutions and a flexible manufacturing capacity, Lesjöfors is the premier partner for all spring requirementsHome Lesjöfors Industrial Springs and PressingsBILSTEIN Sweeps the Podium in LOORRS Championship BILSTEIN short course racers did it again in rounds nine and ten of the Lucas Oil OffRoad Race Series (LOORRS) with two additional podium sweeps – bringing them to a total of five BILSTEIN sweeps in the 2020 Pro 2 seasonHomepage BILSTEIN

Original EquipmentStyle Replacement Springs for Passenger

ADVANCED DESIGNS FOR NEWER VEHICLES The Monroe spring range includes the latest technology sideload compensation front springs and tapered wire miniblock rear springs for many newer vehicles A leading choice of vehicle manufacturers, sideload compensation front springs feature sophisticated parabolic shapes that help provide optimal vehicle control at all speedsApproximately onethird of defective springs result from production problems The other twothirds are caused by deficiencies in the wire used to form the springs In 1998, reers reported the development of a wire coilability test (called FRACMAT) that could screen out inadequate wire prior to manufacturing springsHow springs is made material, manufacture, making