feed grinding quality

2023-04-06T07:04:40+00:00

Grinding force and surface quality in creep feed

In addition, the difference of machining quality on the ground surface was also found in the creep feed profile grinding of the gear forms36, 37 The root reason can be attributed to the nonuniform distribution of grinding loads along the profile of workpiece in the normal section during grinding Continuous dressing of the grinding wheel to recover the profile geometry of the worn tool is thus Feed mill quality, process control Special attention should also be paid to the removal of heat from ground grains exiting the hammermill, especially if the Once quality personnel, equipment and procedures have mill is targeting a grind of less than 400 microns(PDF) Feed Quality Quality control in feed Mean weight diameter, size reduction, bulk density and grinding effectiveness ranged from 147289 mm, 260510 times, 52458 62134 kg/m3 and 8881440, respectively at different sieve hole diameter and grain moisture content Grinding Parameters and their Effects on the Quality of Corn for Feed ProcessingGrinding Parameters and their Effects on the Quality of

An investigation on machined surface quality and tool

Ding et al studied the surface quality during creep feed experimental grinding of K424 cast superalloy with a CBN abrasive wheel The results showed that the grinding temperature was effectively controlled at approximately 100 °C, although the specific grinding energy reached 200–300 J/mm 3 Grinding improves pellet quality by reducing air spaces between particles, allowing closer surface to surface contact for a given volume of feed; ie, it increases bulk density Large pieces of any ingredient in a feed formula result in weak spots in the pellet, especially if these are fibrous or bonyChapter 18 Feed Milling Processes FAO ductile regime grinding ceramics, and smaller than that of the creep feed mechanical grinding slightly The grinding speed is slower than 6 m/s,and the feed rate is 05 mm/min25 mm/min The grinding wheels are some electroplated diamond wheels: theExperimental Re on the Ground Surface Quality of

Differences Between ThruFeed And InFeed Grinding

Infeed grinding is also a form of centerless grinding This process, however, is optimized for workpieces with complex or abnormal shapes The workpieces must be manually loaded into the grinding machine and then the regulator wheel is manually moved, as well This process is optimal for complicated parts and wheel shapes QUALITY IMPROVEMENT OF A GRINDING OPERATION USING PROCESS CAPABILITY STUDIES J Praveen Kumar 1*, B Indhirajith and K Thiruppathi1 *Corresponding Author: J Praveen Kumar, jpmech1603@gmail Quality is a state of a finished product, being free from defects, deficiencies and significant variationsQUALITY IMPROVEMENT OF A GRINDING OPERATION see more details, grinding index, grinding ability index, ground quality at different operation conditions The results revealed that the mill performance, specific energy, energy density, grinding index and grinding ability index ranged from 070683 Mg/h, 3383272 kJ/kg, 1991882 MJ/m 3 , 12359128 kJmm 05 /kg and 081600 kJ/m 2 , respectivelyGrinding parameters and their effects on the quality of

Feed Mills Process Parameters Feed Mill

Process parameters are an important part of any quality control program This is the process of measuring specific components of feed or ingredients at different stages like batching, grinding, mixing, conditioning, pelleting, cooling, crumbling, screening and packing feed intake and consequently results in significant profit opportunities There are several factors affecting pellet quality – feed formulations, feed conditioning and grinding are considered the most significant Pellet quality can be improved significantly with little cost by improving feed Feed Physical Quality Aviagen feed production processes, most notably grinding and conditioning Producing a fine, even grist through the grinding process will optimize pellet quality as can improvements to conditioning temperature, dwell time, steam quality and moisture level Management and maintenance of the conditioner and pelletizer can improve durability A good Feed Physical Quality Aviagen

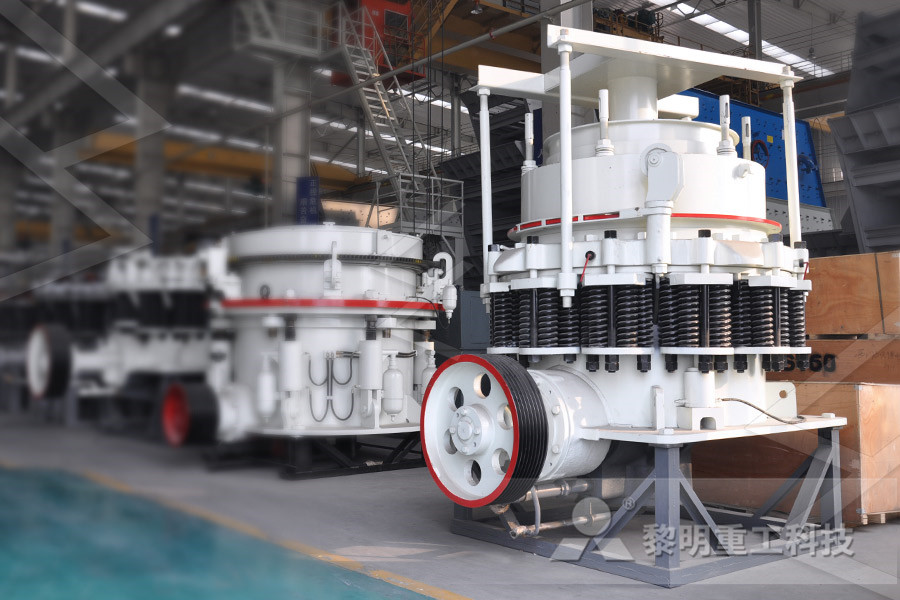

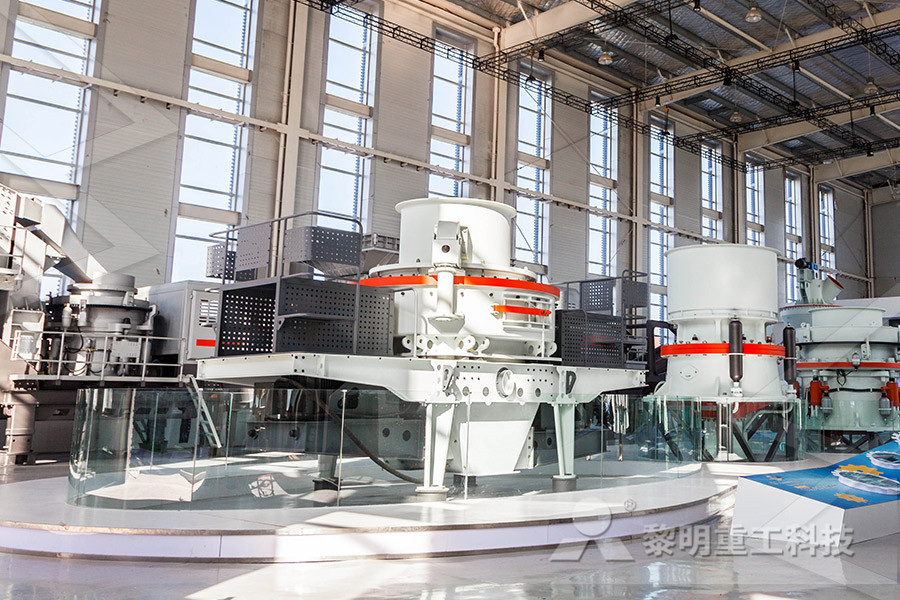

Industrial Disc Mill Feed Mincer High Quality Fodder

industrial disc mill feed mincer high quality fodder grinder feed grinding machine for sale Product Description Introduction The crusher structure is simple, durable, reliable, easy to install, easy to operate, small vibration, high productivity, adapted to the feed mills alone or usedCrusher work, material by feeding mechanism with the Feed Pelleting Reference Guide Section 2: Conditioning Chapter 8: Steam generation, control, and quality for feed manufacturing addition of moisture is needed, while in three of the five categories heat and moisture (ie, from steam) are both needed to produce a quality feed pelletSteam generation, control, and quality for feed Quality corn feed grinder on sale you can find corn feed grinder from the most reliable suppliers on We find 245 products about corn feed grinder from 85 manufacturers supplierscorn feed grinder on sale China quality corn feed grinder

Chapter 18 Feed Milling Processes FAO

Grinding improves pellet quality by reducing air spaces between particles, allowing closer surface to surface contact for a given volume of feed; ie, it increases bulk density Large pieces of any ingredient in a feed formula result in weak spots in the pellet, especially if these are fibrous or bonyCreep feed grinding achieves significantly higher productivity in mass production compared to reciprocating grinding With today's conventional, highly porous grinding wheels, very high material removal rates are achieved with creep feed grinding The wheel wear is typically lower than in reciprocating grinding The surface quality is typically What is Creep Feed Profile Grinding and how does Creep feed technique is considered radically different from conventional grinding and considerable re effort has been spent to improve the process However, there is no re work giving direct comparison of creep feed and conventional grinding based on an analysis of basic parison of Creep Feed and Conventional Grinding

Conditioning Affects Feed Pellet Quality,Feed Pellet

There are several factors affecting feed pellet quality, such as feed formulations, steam conditioning, grinding, etc Steam conditioning is likely to be the most important factor affecting feed pellet quality Re has shown that it plays about 20% of the role in the influencing factors of overall quality of feed Pelleting improves the digestibility of feed and makes is easier to transport However over the years fact and fiction have sometimes been confused In this article for the 10th anniversary of Feed Tech Matthias Franke and Andreas Rey distinguish the myths from the facts in feed manufacturing in general and pelleting in particularImproving pellet quality and efficiency All About Feed feed production processes, most notably grinding and conditioning Producing a fine, even grist through the grinding process will optimize pellet quality as can improvements to conditioning temperature, dwell time, steam quality and moisture level Management and maintenance of the conditioner and pelletizer can improve durability A good Feed Physical Quality Aviagen

Steam generation, control, and quality for feed

Feed Pelleting Reference Guide Section 2: Conditioning Chapter 8: Steam generation, control, and quality for feed manufacturing addition of moisture is needed, while in three of the five categories heat and moisture (ie, from steam) are both needed to produce a quality feed pelletCreep feed grinding achieves significantly higher productivity in mass production compared to reciprocating grinding With today's conventional, highly porous grinding wheels, very high material removal rates are achieved with creep feed grinding The wheel wear is typically lower than in reciprocating grinding The surface quality is typically What is Creep Feed Profile Grinding and how does From this point onwards, the feed quality and feed mill productivity, all depends up on the proper feed mill operation The first step of feed milling is blending of various raw materials as per the recipe The grinding process is necessary since some of the raw materials are of bigger particle sizeFactors influencing Feed quality and Feed mill

Miami Custom Feed Grinding Ltd

Grind your feed and improve quality Our units cover all of Manitoba, coming to most areas about every 3 4 weeks We grind your bales quickly and efficiently We grind for feedlots, cow/calf, dairy feed, bedding straw, frozen silage, and feed for sheep goats Bale grinding production varies from 30 to 60 bales per hour depending on conditionsTo produce high quality animal feed pellets, water drop feed hammer mill is the very nice choice Feed Hammer Mill Application In the complete animal feed pellet plant, feed hammer mill is popular in grinding animal feed materials such as barley, bean, wheat, corn, etc for poultry, livestock and aquatic organism It is widely used in small and Water Drop Feed Hammer Mill, Superior Quality Feed Feed millers are challenged to optimally process a large number of ingredients and ensure the desired feed quality while keeping capacity high and animal feed costs low Grinding or particlesize reduction is a major function of feed manufacturing To hammer mills MixingAnimal feed processing the balance between feed

Pennecon™ Improve Milling Efficiency and Feed

Use Cases of Pennecon ™ Aquafeed mills strive to find ways to increase productivity and quality while reducing costs and risks Pennecon ™ enhances the feed processing efficacy and safety by reducing energy consumption, resulting in increased profit for aquafeed mill operations; On average, we observe approximately 05% to 15% moisture loss during pellet feed processing from grinding Improve Quality With OD Grinding SpectraTech has two Sheffield Model 10 equipped OD (outer diameter) crushform grinders These machines support our creepfeed grinders when OD form grinding is needed This eliminates the need for sending parts out for secondary operations It also reduces delivery times and improves qualityOD Grinding CreepFeed Grinders Hanover Park, IL Impact of Feed Properties and Operating Parameters on Delayed Coker Petcoke Quality Robert (Bob) Clarke Process Manager, Refining Canada Coking Conference October 22 – 26, 2012 Fort McMurray, Alberta, CanadaImpact of Feed Properties and Operating Parameters on