Line Crusher Selection

2019-01-01T15:01:33+00:00

Selection Of Line Crusher divinechannel

Selection Of Crusher Based On Iron Ore Type Peru The selection of iron ore crusher the common problem in the iron ore crushing production line is that the wear parts of the fine crusher are seriously worn out and the repair and maintenance of the fine crusher are too frequent which makes the production efficiency of the iron ore crushing production line lower shorthead type coneCRUSHER SELECTION QUICK GUIDE 1 A typical example of primary crushing is reducing topsize from 900 to 300 mm 2 A typical example of secondary crushing is reducing your bottom line INCREASE REDUCTION OR REDUCE f INES – consider your opTiMal ouTpuT 75 mtph 81 mtph 81 mtph 81 mtph Feed 5–45 mm 59 mtph 6 mtph 16 mtphMASTER YOUR OUTPUT CRUSHER SELECTION QUICK Example: The HP crusher chamber selection table shows the minimum opening settings However, the presented settings are provided as a guide only The actual minimum setting is at which the crusher will operate without causing ring bounceSelecting crushing chambers for cone crusher

Selection Of Crusher Based On Iron Ore Type Peru

The selection of iron ore crusher the common problem in the iron ore crushing production line is that the wear parts of the fine crusher are seriously worn out and the repair and maintenance of the fine crusher are too frequent which makes the production efficiency of the iron ore crushing production line lower shorthead type cone GYRATORY CRUSHER 1Height required will be too high 2Difficulty in removing spares and fixing in UG 3Discharge product in down line operation 4Removal of shift, lifting shaft in UG is a difficult task 5Feeding is also to be thought 6Storing and feeding UG big size boulders may be difficultUnderground Crusher Selection and Design Crushing Jaw crusher selection is also heavily influenced by the subjective judgment/experience of individuals, which can result in the conservative selection and operation of jaw crushers The prediction of crusher performance is typically concerned with the size distribution of the product exiting the crusher, the machine’s power draw, and the capacityJAW CRUSHER SELECTION AND PERFORMANCE

Jaw crusherIron Selection Equipment, Mine Selection

Henan Bureau of Mines Machinery Co, Ltd offers Iron Selection Equipment, Mine Selection Machine, Rotary Kiln Equipment, etc The company took the lead in the same industry through lS09001: 2000 international quality management system certificationModel Selection Questions ? +91 422 A higher motor power and larger grinding unit allows besides increased grinding power, increased pumping and transport capacity of the grounded food waste through the water trap and into the drain pipeModel Selection Sharp Crusher The machines from the MCO EVOLINE use the innovative "dieseldirectelectric" drive concept Equipped with an efficient, powerful diesel engine with fluid coupling, the cone crushers from the EVOLINE impress with extremely low efficiency losses: the direct crusher drive provides maximum power directly at the crusherMOBILE CONE CRUSHERS MOBICONE EVO Wirtgen Group

Crushing Plant Design and Layout Considerations

• Electronic control of crusher discharge opening and feed rate With adjustment of a crusher’s discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses) Dance, A 2001) • More attention is being paid to the impact on crushing circuit design caused by variations GYRATORY CRUSHER 1Height required will be too high 2Difficulty in removing spares and fixing in UG 3Discharge product in down line operation 4Removal of shift, lifting shaft in UG is a difficult task 5Feeding is also to be thought 6Storing and feeding UG big size boulders may be difficultUnderground Crusher Selection and Design Crushing MOBICONE EVOLINE > CRUSHER UNIT POWERFUL CRUSHER UNIT The heart of the machine D D = 970 mm Crusher system size fully hydraulic Crusher gap adjustment Direct crusher drive via fluid coupling Extensive selection of crusher cone and bowl liners Integrated overload system Cone crusher with a large stroke Convenient crusher gap setting 15 01 MOBILE CONE CRUSHERS MOBICONE EVO Wirtgen Group

Crushing Plant Design and Layout Considerations

• Electronic control of crusher discharge opening and feed rate With adjustment of a crusher’s discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses) Dance, A 2001) • More attention is being paid to the impact on crushing circuit design caused by variationsSite selection and separation Coal crusher classification: In general, coal crushers are categorized into three types, discs, rings, etc, is fixed as far as the main shaft center line is concerned This main shaft carries in roller bearings from the box sides The movable cage frame arrangement is provided so as to set its inner radius Crushers an overview ScienceDirect TopicsCrusher bucket, screening bucket, iron separator and quick coupling are an everexpanding range of products strictly certified, whose use reduce costs, processing times and transportation of materials, while contributing to the environmentBucket crusher manufacturer crushing machine

al crusher selection criteria schroniskogoldappl

coal crusher selection criteria Pochiraju Industries Ltd Various types of crushers are available for coal crushing The refuse is dewatered and the medModel Selection Questions ? +91 422 A higher motor power and larger grinding unit allows besides increased grinding power, increased pumping and transport capacity of the grounded food waste through the water trap and into the drain pipeModel Selection Sharp Crusher Henan Bureau of Mines Machinery Co, Ltd offers Iron Selection Equipment, Mine Selection Machine, Rotary Kiln Equipment, etc The company took the lead in the same industry through lS09001: 2000 international quality management system certificationJaw crusherIron Selection Equipment, Mine Selection

Mineral Processing Crushing Plant design,

PRIMARY CRUSHER SELECTION CRITERIA • Will it produce the desired product size at required capacity • Will it accept the largest feed size expected • What is the capacity to handle peak loads • Will it choke or plug • Is the crusher suited to the type of crushing plant design • Is the crusher suited for underground or inpit duty In the production process of jaw crusher, elbow plate, jaw plate and other wearresisting parts are subjected to different degrees of impact wear and cutting wear, so manufacturers generally choose high hardness and high toughness materials to produce these wearresisting partsBut hardness and toughness themselves are contradictoryConsequently in actual production, the working Factors influencing the material selection of wear coal crusher selection criteria Pochiraju Industries Ltd Various types of crushers are available for coal crushing The refuse is dewatered and the medal crusher selection criteria schroniskogoldappl

Underground Crusher Selection and Design Crushing

GYRATORY CRUSHER 1Height required will be too high 2Difficulty in removing spares and fixing in UG 3Discharge product in down line operation 4Removal of shift, lifting shaft in UG is a difficult task 5Feeding is also to be thought 6Storing and feeding UG big size boulders may be difficultSelection Of Crusher Based On Iron Ore Type Peru Selection of crusher primary crusher selection criteria will it produce the desired product size at required capacity will it accept the largest feed size expected what is the capacity to handle peak loads will it choke or plug is the crusher suited to the type of crushing plant design is the crusher suited for underground or inpitSelection Of Crusher Based On Iron Ore Type PeruCrusher operating parameters, liner selection, material selection, plant process review, and customer goals all go into providing our customers with the ideal solutions If more than one option is available, we offer costbenefit options to make the decisionmaking process easier for youCone Crusher Liners

Selection Of Crusher Based On Iron Ore Type

Selection Of Crusher Based On Iron Ore Type Iron ore separation process iron ore separation process xsm excellent mining crushing machinery products or production line design the pany is mitted to building the chinese brand mine crushing and processing machinery mainly crusher mill sand making our products iron ore separation process in more than one hundred of the worldsales of countries and Crusher Manufacturers Line Up Advanced Equipment In accordance with this, we have made our selection of VSI and cone crushers more flexible, so has to accommodate higher volumes of feed materials, for higher production of crushed aggregates with higher reduction ratios and sand”Crusher Manufacturers Line Up Advanced EquipmentMcLanahan offers a wide selection of Impact Crushers for quarried limestone and semiabrasive minerals McLanahan draws from the 75 years of field experience with the Universal line of Impactors, which includes impact breakers and Andreasstyle impactors At present, we offer the New Hollandstyle primary impact breaker and the MaxCap XSeries Primary, providing a means to reduce quarry shot Impact Crushers Primary McLanahan

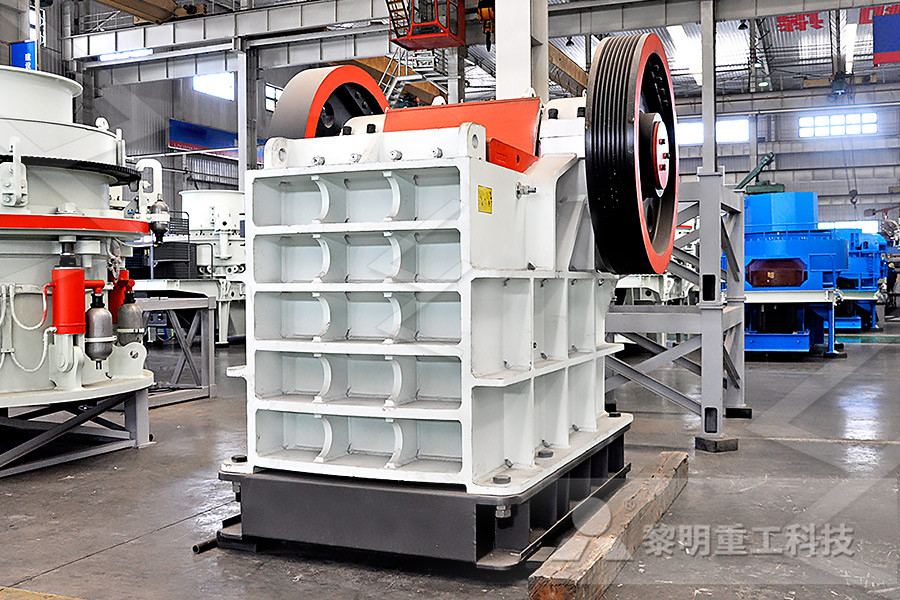

Mobile Jaw Crusher

The selection of equipment for the production line affects the quality of the product and the investment in the processing system Moreover, due to the fixed site selection and long route of the road construction, the required materials are huge and inconvenient to transport, which means that the mobile crushing is the best choice for road Vertical Line Shaft Pumps for slurry and load sharing problems that may arise from poor selection or worn Independant heavy duty bearings ; Keyed shaft Vertical Shaft Impact Crusher(VSI) – Jaw Crusher, Hammer Vertical Shaft Bearing Selection Crusher Mills, Cone Along with selection of the proper crusher, the proper screens and feeders need to be made Some of the information required to select the proper screen or feeder are listed below: Feed size Feed gradation Tons per hour Type of screening media (wire cloth, urethane, etc) Wet or dry processPQ University Lesson 2 Site Selection Plant