grind separate processing plant iron ore

2019-04-21T22:04:09+00:00

grind separate processing plant iron ore in Belgium

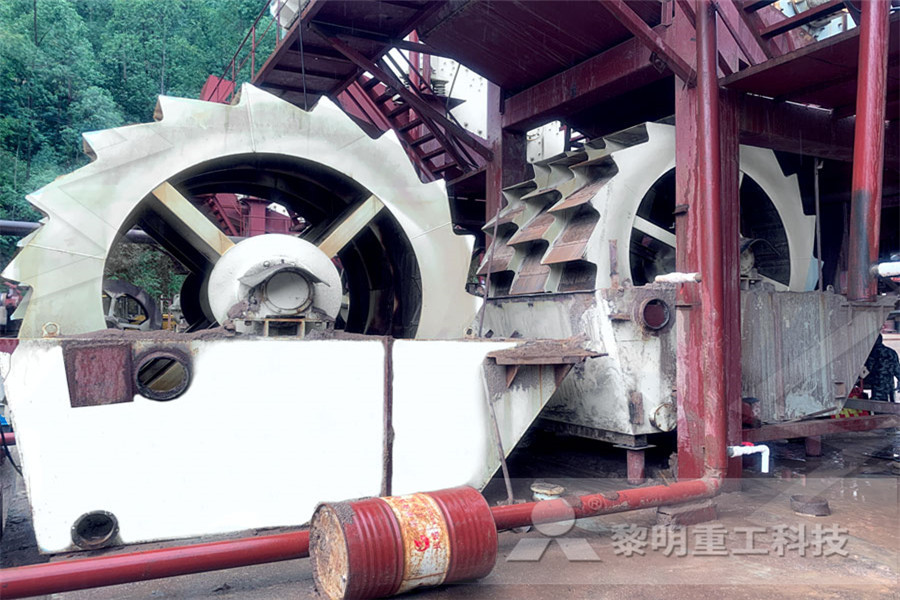

The crude ore that has been extracted and hauled up to surface level then enters a sorting plant where the main task is to separate the iron ore from gangue and grind the ore down to smaller particles In the sorting plant, both magnetite ore and hematite ore areGrind Separate Processing Plant Iron Ore 3This iron ore slurry is pumped to the agitation tank This iron ore slurry is finally pumped to the flotation machine with the fine sulfide ore 0074 mm going to froth flotation cells for recovery of iron 4In magnetite processing plant,the process of flotation separation is replaced by magnetic separationGrind Separate Processing Plant Iron OreChina Good Qulaity Iron Ore Processing Plant with Reasonable 4) The washed and classified fine ore particles will be sent to the magnetic separator, making use of minerals susceptibility differences, magnetic separator will separate the magnetic minerals from the fine ore particles mixers by the magnetic force and mechanical force, and get 65% iron ore concentrate「iron ore magnetic separation steel specifiion of

iron ore grinding plant types in chandigarh SmartTech

Jaw Iron Ore Crusher Grind Plant Tehnomag Iron ore processing, iron ore mining, iron ore grinding plant iron oresand crusher 400 meshbelt conveyor pew jaw crusher mtw millingget pricecrusher wikipediajaw crushers are heavy duty machines and hence need to be robustlyis one of the main types of primary crushers in a mine or ore 12/10/2011 Athena Byro Iron Ore project moves to next step with results of 5M tpa magnetite plant prefeasibility study • Study provides for a simple processing circuit comprising crushing, grinding and wet low intensity magnetic separation • Coarse grind size provides savings in both capital and operating costs Plant Capital Cost $136M iron ore processing grind schroniskogoldappliron flotationcell fororedressing plant dmb series stepless reducer for iron ore flotation cell easy to operate jaw iron ore roller crusher iron ore processing from design to operations national iron mineralisation demand of crushed iron ore e4 hot selling iron ore grinding mill for you tunnel kiln iron ore technology used flotation grinding mill for froth flotation of iron ores Bussa

grinding iron ore operations Induzin

Ball Mill Grinding Technology For Iron Ore It accounts for up to 40 of the total power consumption in mineral processing plant operations so, selecting the efficient solution for grinding section is very important prominer provides ball mill rod mill grinding system which is widely used in various types of ores beneficiation, electricity, cement and chemical industriesPRE FEASIBILITY REPORT Godawari Power Ispat Limited (Iron Ore Beneficiation Plant) Prefeasibility Report 5 2009 Iron Ore mining operations started at Ari Dongri, Dist Kanker 2009 Further expansion for installation of 20 MW Biomass Power Plant, Iron Ore Beneficiation 10,00,000 TPA, Rolling Mill 3,00,000 TPA Arc Furnace 5,000 TPA 2010 Commissioning of Iron beneficiation of iron ore plant operations grinding mill The ore processing facility (OPF) at Firetail will process bedded iron ore for the first two years of mining The deposits will be dryprocessed for the direct shipping of ore The ore is crushed in the primary crushing hub and transported back to the OPFs for grinding and separationore crushing and grinding facility Escort

Beneficiation Plants and Pelletizing Plants for Utilizing

1 Iron ore supply and demand outline 11 Types of iron ore Iron ores can be classified in different ways The most important has to do with the iron content In many cases, ore with a total iron content of 60% to 63%, or greater, is regarded as high grade, and ore with a lower iron content is regarded as low gradeProcess Of Iron Ore Processing Plant Screening: The first one is screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage Crushing and stockpiling: This step involves breaking up the iron ore to obtain an F80 grind size before it can be ground Once the ore is crush, it is diverted to a stockpile and then fed into the millIron Ore Processing Plant Iron Ore Processing Plant Iron Ore Magnetic Separation Process In a complete iron ore magnetic separation processing plant, we need not only the magnetic separator but also the crushing screening and grinding equipment In the crushing screening stage, we need primary crusher and secondary crusher to crush the bulk iron ore into proper sizes to enter the grinding millIron Ore Magnetic Separation Processing Plant Design

Iron Ore Processing Grind mayukhportfolioco

iron ore processing grind, pew series jaw crusher is born with innovative significance It is newly designed and improved by our experts on basis of their more than Read more iron ore grind size sinter Iron ore processing plant design,iron ore mining machine,grinder Iron ore processing plant is composed of preparation operation: Grinding Mineral Processing The selfgrinding machine can grind ore without grinding media such as iron ball, or steel rod, as long as the hardness of the ore is sufficient for the rolling ore to grind by itself A large vibrating screen is used to sieve the ground products to separate the oversized particles A small cone crusher to recover the oversized material, and then sent them can ball mill grind iron ore comprensivopievetorinaitStrong magnetic iron ore separation process It is used to low grade magnetite Due to the strong magnetic and easy to grind, one stage grinding is adopted for magnetite with coarse particle distribution, conversely the multi stages grinding At present the fine grinding technology promoted by Xinhai improves the concentrate grate from 61% to 67%Magnetic Separation Process Xinhai

iron ore processing plant mineral beneficiaton machine

Hematite Iron ore crusher and Hematite iron ore grinding machine will be the very first step in Hematite iron ore processing plant Ore crushed by means of the thick the block is no more than 1m and then through the medium and fine crushing and screening ore particle sie less than 12mm into the final item sent to the grinding grooves The plant operating results for this flow sheet showed that an iron ore concentrate containing 520% Fe could be produced from a runofmine ore containing 404% Fe, at a mass yield to the iron concentrate of 575%, an iron recovery of 741%, and a tailings grade of 246% FeDevelopments in the physical separation of iron ore Processing the iron ore Onboard the IMV the processing plant will use magnetic separation and for a portion of the seperated sediment a grinding mill is required to lightly grind the sediment to separate the iron ore concentrate This process will be completed wet using seawater No heat, chemicals or additives will be used in the processSouth Taranaki Bight TransTasman Resources

Energy analysis of pelletising in a straight grate

The crude ore that has been extracted and hauled up to surface level then enters a sorting plant where the main task is to separate the iron ore from gangue and grind the ore down to smaller particles In the sorting plant, both magnetite ore and hematite ore are processed, but in Within a few years, several companies were competing to mine, ship, and process the magnetite and hematite ore in the area, which was so abundant and accessible that chunks could be pulled off the surface and shipped directly to steel mills with little or no processing But by the 1950s, most of the easily accessible ore with high Iron Mines in Michigan NASA Earth ObservatoryProcess Of Iron Ore Processing Plant Screening: The first one is screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage Crushing and stockpiling: This step involves breaking up the iron ore to obtain an F80 grind size before it can be ground Once the ore is crush, it is diverted to a stockpile and then fed into the millIron Ore Processing Plant Iron Ore Processing Plant

Magnetic Separation, Magnetic Separation Process,

Strong Magnetic Iron Ore Processing Technology It is mainly used for lowgrade magnetite ore As for the strong ore magnetism, easy to grind and separate, the coarsegrained magnetite common uses twostage grinding, othervise the multiplestage grinding flow is usedHematite Iron ore crusher and Hematite iron ore grinding machine will be the very first step in Hematite iron ore processing plant Ore crushed by means of the thick the block is no more than 1m and then through the medium and fine crushing and screening ore particle sie less than 12mm into the final item sent to the grinding groovesiron ore processing plant mineral beneficiaton machineDue to the low grade of the iron ore, the stages grinding and stages separation could reduce energy consumption Cost saving is the key of developing the mine The fine grinding process has guide significance for similar iron ore Case 2 —— Shanxi 1,200t/d Iron Mineral Processing PlantMagnetic Separation, Magnetic Separation Process,

Iron ore Beneficiation Plant FTM Machinery

What is iron ore beneficiation plant? According to different physical and chemical properties of the ore, using the gravity method, flotation method, and magnetic separation method to separate useful minerals from crushed gangue minerals and decrease harmful impurities in the beneficiation processprocessing methods for iron ore As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of mineralsprocessing methods for iron ore homecucinepl 1 Iron ore supply and demand outline 11 Types of iron ore Iron ores can be classified in different ways The most important has to do with the iron content In many cases, ore with a total iron content of 60% to 63%, or greater, is regarded as high grade, and ore with a lower iron content is regarded as low gradeBeneficiation Plants and Pelletizing Plants for Utilizing

METHOD FOR PROCESSING IRON ORE

METHOD FOR PROCESSING IRON ORE CONCENTRATES United States Patent Abstract: A water slurry of an iron ore concentrate from concentration equipment, for example, magnetic separators in a primary circuit containing fine high grade mineral particles, coarse low grade middling particles and coarse high grade mineral particles, is pumped Ilmenite ore mining is usually made use of for creating iron ore and related solutions in ore processing plants with mineral equipments including ilmenite ore crusher , ilmenite ore grinder machine, ilmenite ore feeder , screening equipment , etcLlmenite Ore Crushing and Grinding Machines liajones 博 As is known to all, the dressing operation consists of three stages: predressing, dressing and postdressing The preparatory work before mineral dressing generally includes crushing and screening, grinding classification, hand sorting and washing, among which grinding classification is the followup technology of crushing and screening and also an important process in the predressing stageDo You Understand The Grinding And Classifying