jaw crusher swing bearing

2021-09-20T13:09:29+00:00

Jaw Crusher

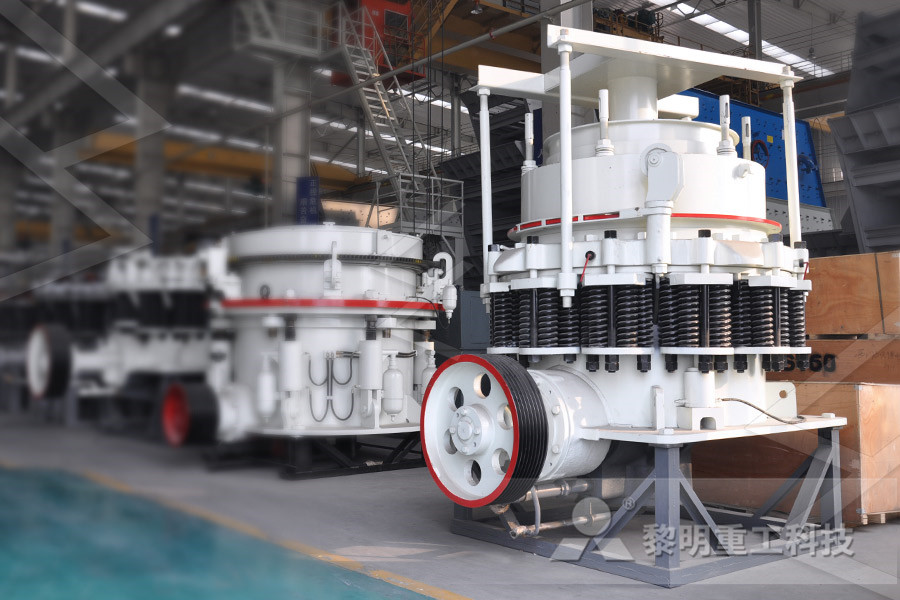

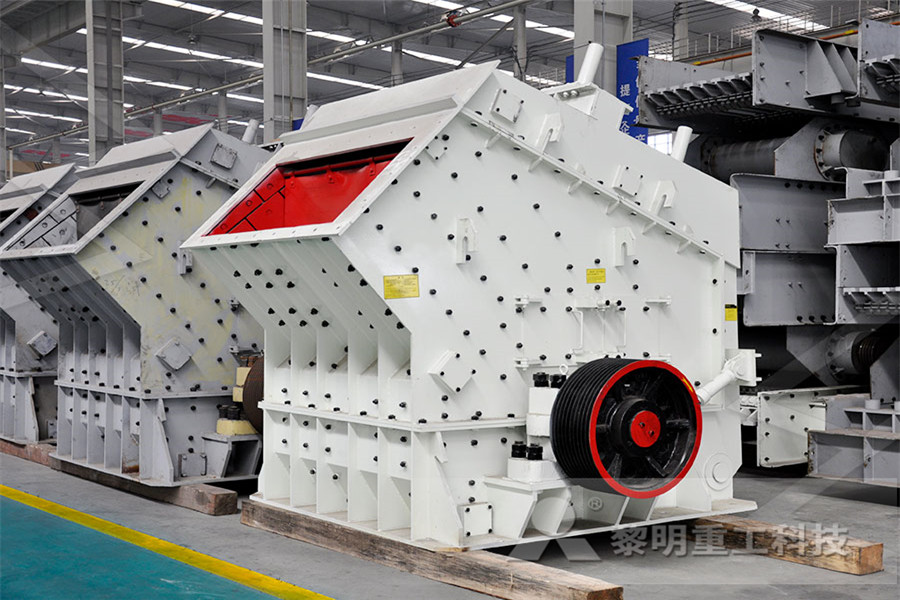

Jaw Crusher Bearings: Fag or SKF heavy duty selfaligning double row bearings on swing jaw and main frame Bath oil lubrication ensures positive lubrication Bearing life in excess of 8 years under typical quarry applications Crusher Swing Jaw Repair Customer Challenge: The bearing on the swing jaw of a key piece of operational equipment in a large quarry was failing inservice too regularly and frequent downtime taken to repair it had not resolved the issuesCrusher Swing Jaw Repair DMM engineeringJaw crusher bearing size x jaw crushers are sized by the top opening of the crushing chamber for example a 32 x 54 jaw crusher measures 32 from jaw die to jaw die at the top opening or gape opening and 54 across the width of the two jaw dies the narrower bottom opening of the crushing chamber is used to size the discharge material DetailsBearing Size For Jaw Crusherjaw Crusher

Jaw Crusher In Mounting Bearings

Improving Productivity Of Jaw Crusher Through Otif jaw crusher around 250 MT of loose bath is crushed per day 1 5 6 11 Figure 1 Jaw Crusher Reshifting of crank shaft assembly to crusher area fitted with new bearing Crank shaft assembly mounting on crusher inspection Read More; Bearing Jaw Crusher A reasonable swing jaw structure is a sufficient condition to ensure the superior performance of the jaw crusher, so the strength and stiffness of the swing jaw directly affect the performance and production efficiency of the equipmentCrusher swing jaw partscasting Pitman bearing broken Although the main crushing process is complemented by jaw plates, the crucial parts that give a motion to the moveable jaw plate are toggle plate, pitman bearing and flywheel The pitman drives the moveable jaw dies to push stone material towards stationary jaws, which would create strong pressing forces to both jaw diesThe Most Practical Jaw Crusher Repair and

Jaw Crusher Primary Crusher in Mining Aggregate

It uses curved plates to avoid the near the discharge of jaw crusher blocking The bottom of the swinging jaw is concave, and the relative lower part of the fixed jaw is convex The materials reduction in size when nears the exit So the material is distributed over a larger area, and the jaws The Jaw Crusher is ideal for stationary, skidmounted, or portable and bearing in on pitman and block for easy boltin removal and replacement More details 13 Jun 2014 bearing removal erin jaw crusher, Links: goo /DII9h4 More details : goo /N1nfWU (Hot!!!) is quite experienced inhow to replace jaw crusher bearing In order to optimize bearing life, only tapered roller bearings are used in jaw crushers The tapered bearings offer a combination of features that spherical bearings are unable to provide When considering the adjustable clearance, line contact, true rolling motion and ability to carry both radial and thrust loads, the tapered roller bearing is an obvious choice for all jaw crushersJaw Crushers Rock Crushers Aggregate Crusher

Jaw Crusher Components Parts 911 Metallurgist

The toggle plates are set at an angle to the arm and the swing jaw As the pitman is revolved the arm is pulled up This causes the toggle plates to come to the horizontal position The movement of the toggle plate forces the swing jaw to be Bearings In Jaw Crusher Bearing plays important role in the modern mechanical equipment Bearing is a component that fixes and reduces the load friction coefficient in the transmission process of machinery In other words, bearing is used to reduce the friction coefficient in the power transmission process and keep the axis stay in the centerBearings In Jaw CrusherCrusher Swing Jaw Repair Customer Challenge: The bearing on the swing jaw of a key piece of operational equipment in a large quarry was failing inservice too regularly and frequent downtime taken to repair it had not resolved the issuesCrusher Swing Jaw Repair DMM engineering

Bearing In Jaw Crusher

Jaw Crushers778 Кб Bearings Bearing mounts Eccentric shaft Flywheel • • • The pitman runs on spherical roller bearings Swing jaw pivots with bronze bushes, on a concentric shaft Eccentric shaft actuates a vertical pitman connected to a pair of toggle plates, and is not directly exposed to crushing loads Note: Crusher output A reasonable swing jaw structure is a sufficient condition to ensure the superior performance of the jaw crusher, so the strength and stiffness of the swing jaw directly affect the performance and production efficiency of the equipmentCrusher swing jaw partscastingThe swing jaw is activated by an eccentric main shaft which lifts and thrusts the swing jaw towards the fixed jaw, thus creating the crushing action The crusher discharge setting (CSS) is variable by mechanical shim adjustment of the swing jaw behind the toggle plateJaw Crusher Powertrac Building a Better Future

Bearing Size For Jaw Crusherjaw Crusher

Bearing Size For Jaw Crusher Pe 250 X 1000in Bangladesh Bearing size for jaw crusher pe 250 x 1000in bangladesh pe 250 x 400 jaw crusher diesel engine powered maximum input size 200 mm output size 2050 mm mobile crushing plant for sale philippines with jaw and impact mobile jaw crusher and mobile impact crusher are well sold mobile crushing plant for granite conbearing size for jaw crusher Figure 2 Laboratoryscale jaw crusher at the Colombian Geological survey, with the insert showing the top view of the crushing chamber Figure 3 shows the jaw crusher scheme indicating the main components of the machine and the operating variables such as the discharge opening and the displacement of the swing jaw Figure 3DEM Simulation of LaboratoryScale Jaw Crushing of a Nesans premium range jaw crushers are higher capacity stone or mineral processing crusher used in the primary stage and secondary stage of crushing That is to designed for the capacity range from 50 to 400 TPH, our jaw crushers shall be put into use for stones and minerals with varying crushing and abrasive indexJaw Crusher Nesans Mining and Automation Private

Jaw Crusher Working Principle 911 Metallurgist

Jaw Crusher Terminology jaw crusher crosssection The horizontal component of motion (throw) at the discharge point of the singletoggle jaw crusher is greater than the throw of the Dodge crusher at that point; in fact, it is about threefourths that of Blake machines of similar shortside receivingopening dimensions The combination of favorable crushing angle, and nonchoking jaw The Jaw Crusher is ideal for stationary, skidmounted, or portable and bearing in on pitman and block for easy boltin removal and replacement More details 13 Jun 2014 bearing removal erin jaw crusher, Links: goo /DII9h4 More details : goo /N1nfWU (Hot!!!) is quite experienced inhow to replace jaw crusher bearingCrusher Swing Jaw Repair Customer Challenge: The bearing on the swing jaw of a key piece of operational equipment in a large quarry was failing inservice too regularly and frequent downtime taken to repair it had not resolved the issuesCrusher Swing Jaw Repair DMM engineering

Crusher swing jaw partscasting

A reasonable swing jaw structure is a sufficient condition to ensure the superior performance of the jaw crusher, so the strength and stiffness of the swing jaw directly affect the performance and production efficiency of the equipmentThe swing jaw is activated by an eccentric main shaft which lifts and thrusts the swing jaw towards the fixed jaw, thus creating the crushing action The crusher discharge setting (CSS) is variable by mechanical shim adjustment of the swing jaw behind the toggle plateJaw Crusher Powertrac Building a Better FutureWHAT IS A JAW CRUSHER? / JAW CRUSHER Swing Jaw 10 Discharge 11 Fixed Jaw Jaw Crusher Parts G: Gape width, b: maximum feed size, In singletoggle jaw crushers, the movable jaw is supported by the bearing on an eccentric shaft driven by the pitman to which it is attached The pitman is supported by a toggle plate at the bottom of the What is a Jaw Crusher? – MEKA Crushing Equipment

Bearing Size For Jaw Crusherjaw Crusher

Bearing Size For Jaw Crusher Pe 250 X 1000in Bangladesh Bearing size for jaw crusher pe 250 x 1000in bangladesh pe 250 x 400 jaw crusher diesel engine powered maximum input size 200 mm output size 2050 mm mobile crushing plant for sale philippines with jaw and impact mobile jaw crusher and mobile impact crusher are well sold mobile crushing plant for granite conbearing size for jaw crusher how to change bearings on a jaw crusher Crusher Bearings Knowing the basics leads to bett Mar 03 2016 Bearing speeds and loads are generally moderate but on occasion the load spikes as uncrushable material passes through the chamber In a typical jaw crusher two outer bearings located on either side of the main frame support an eccentric shaft while two inner bearings support a moveable jaw how to change bearings on a jaw crusher Since the large and medium jaw crusher bearings and the eccentric shaft are pressure cycle lubrication, when the oil pump fails, the jaw crusher needs to swing the power for 1520 minutes to stop, so it is necessary to press the oil pump to apply oil to the bearing Keeping it lubricated, there is no accident of burning the bearing 3Jaw Crusher Lubrication Knowledge Analysis 201909

Jaw Crusher Handbook Stone Crusher PDF JXSC Mine

This jaw crusher handbook that we hope can help you to learn more about the stone crusher jaw crusher working principle When the jaw stone crusher working, the motor drives the belt and Pulley, moves the movable jaw up and down through the eccentric shaft The angle between the bracing plate and movable jaw gets bigger when the jaw rising The LT110 Jaw Crusher An Optimal Bination The LT110 Jaw Crusher an optimal bination of high crushing capacity and ease of transports This plant is an excellent solution for efficient primary crushing either as a stand alone unit or in bination with secondary and Etso Model C140 Jaw Crusher Jaw crusher is used to crush large block of rocks into required granularity, preparing for the following crushing step Undoubtedly, the spare parts of jaw crusher would be worn out or damaged What reason cause the spare parts wear out? Jaw plate Jaw plate brittleness, particle size, and density change may cause the wear of jaw plate At the same time, the speed of eccentric shaft is too What Reason cause the Spare Parts of Jaw Crusher