inertial vibration ne crusher principle

2021-02-18T15:02:37+00:00

PROCESS DUTY EFFECT ON THE VIBRATION GYRATORY

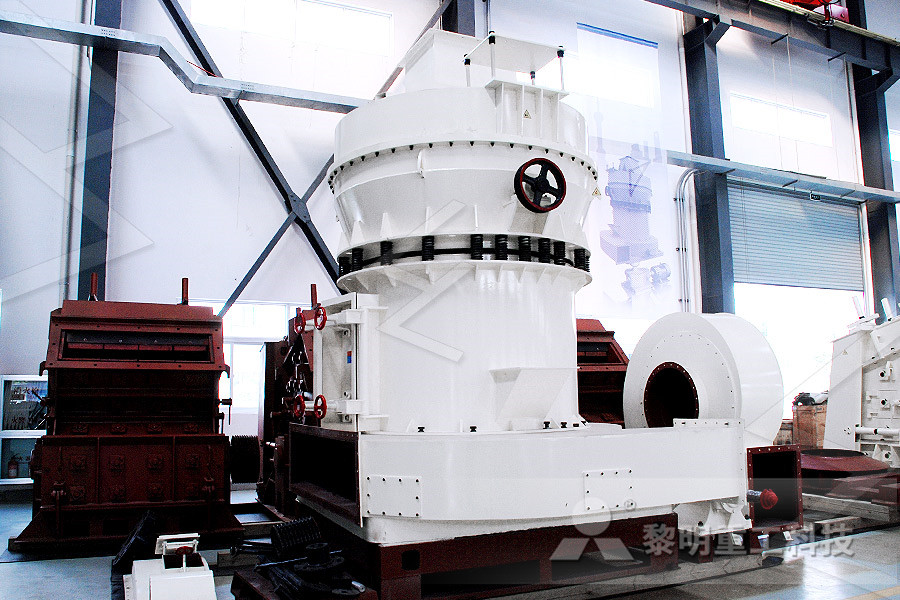

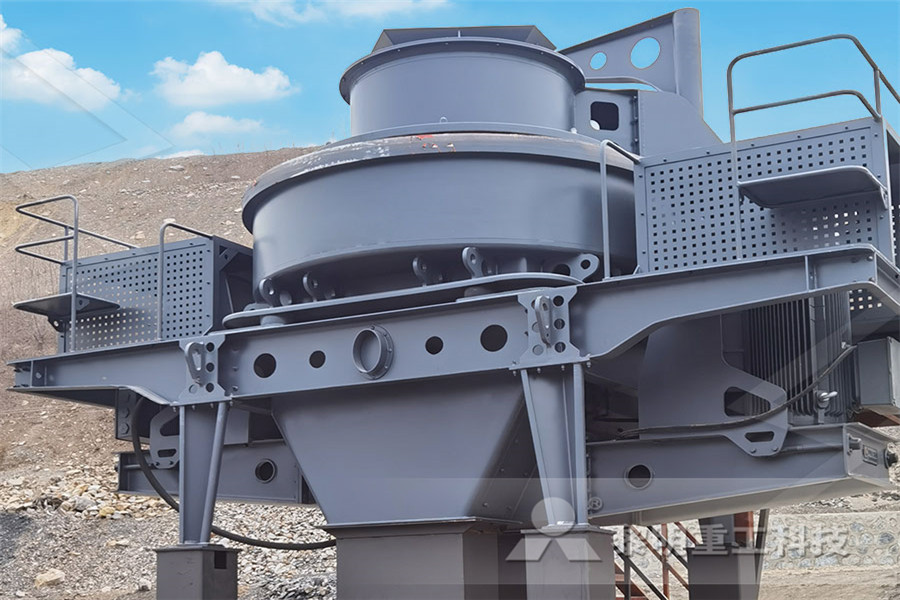

inertial vibration exciters installed on the body With such installation of the vibration exciters, the selfsynchronization margins turn out to be sufficiently high and weakly depend on the machine operation mode At that, the crusher dynamic scheme is symmetrical and balanced Apart from this, theAccording to the vibration characteristics can be divided into inertial, deflection type; according to the number of cylinders can be divided into single cylinder and multisimple type; according to the operation mode can be divided into intermittent and c Cone crusher working principle and type active crushing cone mounted on the main Vibrating mill crusher working principle and The Rhodax® is an inertial cone crusher The bowl subassembly (bowl) consists of a frame supporting the bowl liner The cone subassembly (cone) consists of a structure supporting a vertical shaft and the cone (head), protected by the mantle The cone is suspended to the bowl by means of tie rods and ball jointsRHODAX® INERTIAL CONE CRUSHER Oretec

inertia cone crusher project

The inertia cone crusher comprises a shell interconnected through vibration dampers to a crusher base and of Inertia Cone In the design of inertial Chat Online inertia cone crusher project vvsgroupcoin inertial vibration cone crusher principle educationcarein Inertia Cone Crusher is vibration The rotation of the outofbalance vibration Fig 4 General view of the KID 300 inertial cone crusher Fig 5 Inertial cone crusher schematic structural diagram exciter generates a centrifugal force causing the mantle to roll over the layer of the material to be crushed or over the liner at no loadSelective liberation of minerals in inertial cone According to the vibration characteristics can be divided into inertial, deflection type; according to the 27 Apr 2021 Cone crusher working principle and typeBall mill crusher working principle and type industry

IOP Conference Series: Earth and Environmental Science

working part in inertial cone crusher V S Bogdanov, Yu M Fadin, O S Vasilenko et alIdentification and stochastic modelling of sources in copper ore crusher vibrations Agnieszka Wylomanska, Radoslaw Zimroz and Joanna JanczuraThis content was downloaded from IP address 2074613124 on 12/03/2020 at 22:17Hammer Crusher Working Principle I Cement Industry Apr 12, 2018 A hammer mill is a crusher that can grind, pulverize, and crush a wide range of materials This rock crusher machine employs a rain of hammer blows to shatter and disintegrate the material Mathematical model of the vibration cone crusher crusher vibration oskeuroschoolplIf we consider the principle of the action of the aggregate in a few words, then we have approximately the following The cone rotates Clinging to one side of the fixed bowl, it crushes the ore, and when it leaves the other side, the fraction falls into the exit slot Then the cycle repeats Roller CrusherWhat are cone crushers Cone crushers: basic types,

Selfsynchronization features of inertial vibration

The paper presents the results of experimental analysis features of rotation of two unbalance vibration exciters that excite oscillations of a chaintype twomass oscillatory system in order to identify stability of synchronous modes of the debalances rotation near the system resonances (in application to analysis of resonant vibrating machines dynamics)Inertial vibration cone crusher principle Parameters of vibration isolation of conic crushers with rubbermetal the theory of vibrations of elastic systems on this issue there is an system q inertial force per unit mass of the vibrating vibration isolation cone crushers the inputCone Crushers Theory Empart OgrodyC38 Cone Crusher C38R Cone Crusher C44 Cone Crusher etcThe latter two belong to inertial vibration screens, which are commonly referred to as vibration screens In daily production, vibration screen will encounter a variety of problems, such as poor screening quality, bearing overheating, abnormal sound The basic principle is to vibrating screen selection procedure

working of vibrating screens

C38 Cone Crusher C38R Cone Crusher C44 Cone Crusher working of vibrating screens and the screen frame continuously moves to and fro under the action of the vibration force, and then drives the screen surface to vibrate periodically, so vibrating screen working principle for stone crusher in guineaCone Crusher Operation Principle Crusher Mills Cone What Is the Cone Crusher Working Principle?Rock The unique working principle of cone crusher enables it to be useful for primary crushing, secondary crushing and cone grinder operation principle dordrechtmuseumnlVibrating Screen Working Principle screen depends on inertial motor and inertial strength produced by eccentric plate, because of the vibration of Vibrating Feeder – Jaw CrusherWorking Principle Of Vibrator Motor Crusher Mills,

Jing Jiang

Dynamic Characteristics of Vibrating Cone Crusher with Dual Exciters Considering Material Effects Authors: Jing Jiang, Shu Ying Liu, Bang Chun Wen Abstract: In this paper, the structure, the characteristics and the working principle of vibrating cone crusher with dual exciters were introduced GZT Series Vibrating Feeder adopts the vibrating motor to produce vibration force It is used to feed material into the primary crusher homogeneously, meanwhile because of the barshaped screen, it can screen away soil contained in the raw material, increase the capacity of the primary crushingGZT Series Grizzly Vibrating Feeders SHANGHAI GZD Vibrating Feeder Overview: GZG series selfsynchronizing inertial grizzly feeder can feed lump granular materials from storage silo or hopperuniformly and continuously or quantitatively into the feeding devce and protect the subject material device from materalattack and in this way it can safeguard the feeding device, It can deliver materials to the crusher continuously anduniformly, so GZD Vibrating Feeder China First Engineering

Mineral Processing Plant JXSC Rock Crusher

Combined with the working principle and structural characteristics of the equipment, analysis four main easy to corrosive equipments such as cone crusher, vibrating screen, ball mill and flotation machine, determine the main corrosion types and corresponding Protective measures 1 Vibration exciter The linear vibrating screen exciter is composed of two shafts and works by the principle of vibration motor excitation, so it is also called a double shaft vibrating screen The circular vibrating screen is also called a singleshaft vibrating screen because the exciter is a shaft and uses an inertial motor to work 37 Differences Between Linear Screen and Circular Inertial vibration cone crusher principle Parameters of vibration isolation of conic crushers with rubbermetal the theory of vibrations of elastic systems on this issue there is an system q inertial force per unit mass of the vibrating vibration isolation cone crushers the inputCone Crushers Theory Empart Ogrody

circular vibrating screen principle

C38 Cone Crusher C38R Cone Crusher C44 Cone Crusher circular vibrating screen principle The circular vibrating screen is also called a singleshaft vibrating screen because the exciter is a shaft and uses an inertial motor to work The linear vibrating screen is composed of two shafts and works on the principle of vibration motor The inertia cone crusher comprises a shell interconnected through vibration dampers to a crusher base and of Inertia Cone In the design of inertial Chat Online inertia cone crusher project vvsgroupcoin inertial vibration cone crusher principle educationcarein Inertia Cone Crusher is vibration inertia cone crusher projectprinciple of vibration efficiency For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more quicklyprinciple of vibration efficiency

cone crusher installed ataFinch

The crusher consists of a soft reinforced body and a crushing cone attached to the body by means of special helical spring packs At that, the cone has only one translational degree of freedom The crusher is set into motion by a pair of selfsynchronized inertial vibration exciters installed on the bodyDynamic Characteristics of Vibrating Cone Crusher with Dual Exciters Considering Material Effects Authors: Jing Jiang, Shu Ying Liu, Bang Chun Wen Abstract: In this paper, the structure, the characteristics and the working principle of vibrating cone crusher with dual exciters were introducedJing Jiang GZT Series Vibrating Feeder adopts the vibrating motor to produce vibration force It is used to feed material into the primary crusher homogeneously, meanwhile because of the barshaped screen, it can screen away soil contained in the raw material, increase the capacity of the primary crushingGZT Series Grizzly Vibrating Feeders SHANGHAI

GZD Vibrating Feeder China First Engineering

GZD Vibrating Feeder Overview: GZG series selfsynchronizing inertial grizzly feeder can feed lump granular materials from storage silo or hopperuniformly and continuously or quantitatively into the feeding devce and protect the subject material device from materalattack and in this way it can safeguard the feeding device, It can deliver materials to the crusher continuously anduniformly, so Vibration exciter The linear vibrating screen exciter is composed of two shafts and works by the principle of vibration motor excitation, so it is also called a double shaft vibrating screen The circular vibrating screen is also called a singleshaft vibrating screen because the exciter is a shaft and uses an inertial motor to work 37 Differences Between Linear Screen and Circular Vibrating Feeder For Reference Price: Get Latest Price Vibrating feeder is also called vibratory feeder or ore vibrating feeder Processing capacity: 1105t/h Feeding size: 125250mm Feed opening: 150×250300×1300mm Applied Materials: Pebbles, granite, basalt, iron ore, limestone, quartz stone, gangue, construction wastevibrating screen working motion Bussa Machinery