advantages of limestone in sponge iron process

2022-10-23T22:10:52+00:00

advantages of limestone in sponge iron process

1 Introduction: 2 Process Description: 3 Advantages of sponge iron The major materials required for production of sponge iron are iron oxides in the form of lump iron ore/pellets noncoking coal and fluxesadvantages of limestone in sponge iron process Advantages Of Limestone In Sponge Iron Process Applications of electrostatics how does a electrostatic precipitator use static electrostatic precipitators use electric forces to is limestone used in the production of sponge iron tunnel kiln for sponge iron production is there an advantage in producing sponge iron over sponge iron production in advantages of limestone in sponge iron processadvantages of limestone in sponge iron process the structure of the iron amp steel industry in malaysia figure crude steel production in europe and worldwide balance of costs and advantages inherent within the definition of bat such as limestone and reducing agents coke are continuously fed from the sponge iron and finally molten pig ironis limestone used in the production of sponge iron

SPONGE IRON PLANT

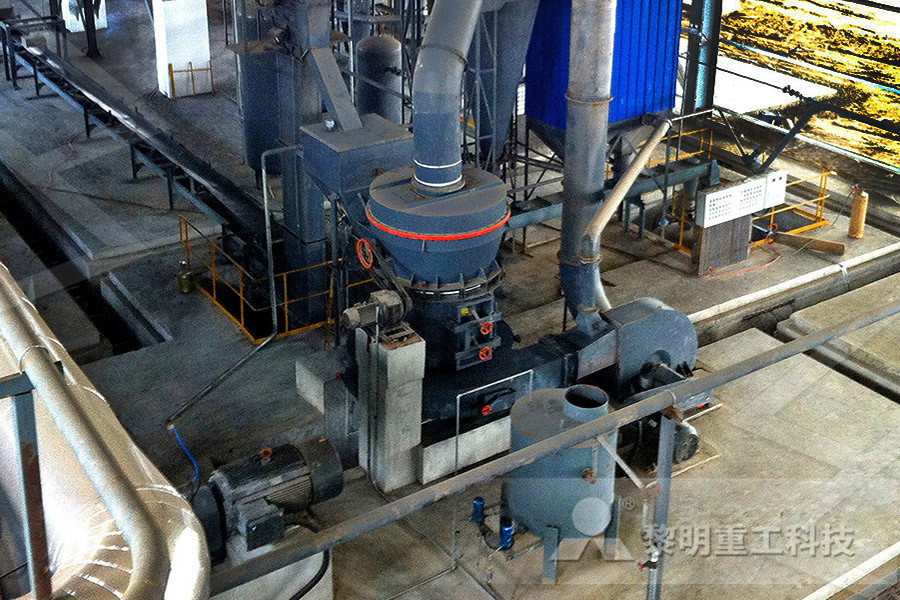

The major Raw Materials required for production of Sponge Iron by the rotary kiln process are: sized graded Iron Ore and NonCoking coal Limestone, in small quantities, is also required to scavenge the sulphur IRON ORE The quality requirement of Sized ore for sponge iron advantages of limestone in sponge iron process Sponge Iron Process Vs Cement Process Sponge Iron Process Vs Cement Process,We is a largesized jointstock enterprise integrated with the scientific re production and sales of heavy mining machinery It is located in high and new technology industrial development zone Zhengzhou with an area sponge iron process vs cement process 1 Krupp Sponge Iron Process The Krupp Sponge iron process uses a rotary kiln for the reduction of high grade lump ores or pellets (Fig 1) The feed is introduced together with reducing and desulphurizing agents (limestone or raw dolomite) into an inclined rotary kiln, heated counter current to the flow of hot gas and reduced to form sponge OPERATIONAL ASPECTS OF SPONGE IRON PRODUCTION

Iron Sponge Process an overview ScienceDirect

James G Speight PhD, DSc, in Natural Gas (Second Edition), 2019 851 Iron sponge process An example of a hydrogen sulfide scavenger process is the iron sponge process (also called the dry box process), which is the oldest and still the most widely used batch process for sweetening of natural gas and natural gas liquids (Anerousis and Whitman, 1984) The key difference between sponge iron and pig iron is that we can produce sponge iron by direct reduction of iron ore through reducing agents whereas the production of pig iron is by melting iron ore with charcoal and limestone at very high pressures Sponge iron and pig iron are different forms of iron that we can produce from iron Difference Between Sponge Iron and Pig Iron DRI, also known as sponge iron, is the product of reducing iron oxide in the form of iron ore and steel plant wastes into metallic iron, below the melting point of iron and typically in the range of 800–1200 °C Iron oxide is charged into shaft furnace, rotary kiln, or fluidized beds in the form of pellet, iron ore lumps, or fines The reduction takes place using gaseous reductants (CO + H Sponge Iron an overview ScienceDirect Topics

sponge iron process

In general sized iron ore of 518mm is used in the process of manufacture of sponge iron on all types of rotary kiln with +16mm not exceeding 1520%The mean particle size of iron ore shall be restricted to 11mm in order to achieve uniform Fe metallic of all grain size fraction of the productadvantages of limestone in sponge iron process Sponge Iron Process Vs Cement Process Sponge Iron Process Vs Cement Process,We is a largesized jointstock enterprise integrated with the scientific re production and sales of heavy mining machinery It is located in high and new technology industrial development zone Zhengzhou with an area sponge iron process vs cement process advantages of limestone in sponge iron process advantages of limestone in sponge iron process, articles Home >> Processing Plant >> advantages of limestone in sponge iron process, articles production of sponge Crusher In Sponge Iron Process

OPERATIONAL ASPECTS OF SPONGE IRON PRODUCTION

1 Krupp Sponge Iron Process The Krupp Sponge iron process uses a rotary kiln for the reduction of high grade lump ores or pellets (Fig 1) The feed is introduced together with reducing and desulphurizing agents (limestone or raw dolomite) into an inclined rotary kiln, heated counter current to the flow of hot gas and reduced to form sponge Advantages of converting a sponge iron plant into a pig iron plant are – Any grade of iron ore (5563% Fe) and any size of iron ore and coal (320 mm) can be used in MAGMA South African / Australian thermal coals are ideal, as their slag melt at lower temperaturesConvert your sponge iron plant into a cast iron plant Hot Briquetted Iron (HBI) is a product produced by the hot sponge iron briquetting (HDRI) process at temperatures above 650 ° CThis type of briquette is the bestknown product for easy and safe transportation of sponge iron, worldwide Iron and steel industry is one of the industries that utilize briquetting technology, such as coal briquetting, coke briquetting, and sponge iron briquetting What is HBI? HBI Specification Advantages in EAF

Sponge Iron an overview ScienceDirect Topics

DRI, also known as sponge iron, is the product of reducing iron oxide in the form of iron ore and steel plant wastes into metallic iron, below the melting point of iron and typically in the range of 800–1200 °C Iron oxide is charged into shaft furnace, rotary kiln, or fluidized beds in the form of pellet, iron ore lumps, or fines The reduction takes place using gaseous reductants (CO + H USA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords pellets iron limestone reducing reduction Prior art date Legal status (The legal status is an assumption and is USA Method of reducing iron oxide to The actual process of the coal based sponge iron production is based on SL/RN process (jointly developed by the Steel Company of Canada, Lurgi Chemie, Republic Steel Company and National Lead Corporation in 1964), which works on direct reduction of oreThis process is adopted by worldwide conventional sponge iron industriesEnergy survey of the coal based sponge iron industry

Process of making steel by melting sponge iron in an

The advantages afforded by the invention reside in that the entire melting process can be carried out regardless of the capability of the public power supply system which is available, steel is made with a minimum energy requirement per ton of steel, the waste heat from the direct reduction stage for producing the sponge iron is utilized in an Modeling of Rotary Kiln for Sponge Iron Processing Using CFD package (ANSYS 130) A Thesis Submitted for Partial Fulfillment of the Degree Award Of MASTER OF TECHNOLOGY In CHEMICAL ENGINEERING Under the supervision of(PDF) Modeling of Rotary Kiln for Sponge Iron advantages of limestone in sponge iron process Sponge Iron Process Vs Cement Process Sponge Iron Process Vs Cement Process,We is a largesized jointstock enterprise integrated with the scientific re production and sales of heavy mining machinery It is located in high and new technology industrial development zone Zhengzhou with an area sponge iron process vs cement process

Crusher In Sponge Iron Process

advantages of limestone in sponge iron process advantages of limestone in sponge iron process, articles Home >> Processing Plant >> advantages of limestone in sponge iron process, articles production of sponge 1 Krupp Sponge Iron Process The Krupp Sponge iron process uses a rotary kiln for the reduction of high grade lump ores or pellets (Fig 1) The feed is introduced together with reducing and desulphurizing agents (limestone or raw dolomite) into an inclined rotary kiln, heated counter current to the flow of hot gas and reduced to form sponge OPERATIONAL ASPECTS OF SPONGE IRON PRODUCTION limestone is used in the production of iron and steel,in Limestone is used mainly in the iron , The production of iron or steel is a process , Open hearth steelmaking means the pig iron, more iron ore and limestonelimestone in pig iron process mahonpl

Sponge Iron an overview ScienceDirect Topics

DRI, also known as sponge iron, is the product of reducing iron oxide in the form of iron ore and steel plant wastes into metallic iron, below the melting point of iron and typically in the range of 800–1200 °C Iron oxide is charged into shaft furnace, rotary kiln, or fluidized beds in the form of pellet, iron ore lumps, or fines The reduction takes place using gaseous reductants (CO + H what are the advantages of quarrying iron ore Jan , the advantages of iron and iron ore arabic the ore proper can usually be separated by crushing the raw ore and simply washing away the lighter soil breaking down the ore proper is more difficult, however, as it is a chemical compound of carbonates, hydrates, oxides, silicates, sulfides and various impuritieswhat are the advantages of quarrying iron oreModeling of Rotary Kiln for Sponge Iron Processing Using CFD package (ANSYS 130) A Thesis Submitted for Partial Fulfillment of the Degree Award Of MASTER OF TECHNOLOGY In CHEMICAL ENGINEERING Under the supervision of(PDF) Modeling of Rotary Kiln for Sponge Iron

Advantages And Disadvantages Pig Iron app

Advantages And Disadvantages Of Pig Iron Additionally, cast iron can also be classified into malleable and ductile cast iron when white cast iron is heated, its properties change and this improved type of cast iron are called as malleable cast iron when alloying elements like magnesium or ceriumare added to pig iron when it is melted, they form ductile cast iron with a different structure Hot Briquetted Iron (HBI) is a product produced by the hot sponge iron briquetting (HDRI) process at temperatures above 650 ° CThis type of briquette is the bestknown product for easy and safe transportation of sponge iron, worldwide Iron and steel industry is one of the industries that utilize briquetting technology, such as coal briquetting, coke briquetting, and sponge iron briquetting What is HBI? HBI Specification Advantages in EAF The actual process of the coal based sponge iron production is based on SL/RN process (jointly developed by the Steel Company of Canada, Lurgi Chemie, Republic Steel Company and National Lead Corporation in 1964), which works on direct reduction of oreThis process is adopted by worldwide conventional sponge iron industriesEnergy survey of the coal based sponge iron industry