steps of iron ore processing

2021-12-07T06:12:53+00:00

The Six Main Steps of Iron Ore Processing Multotec

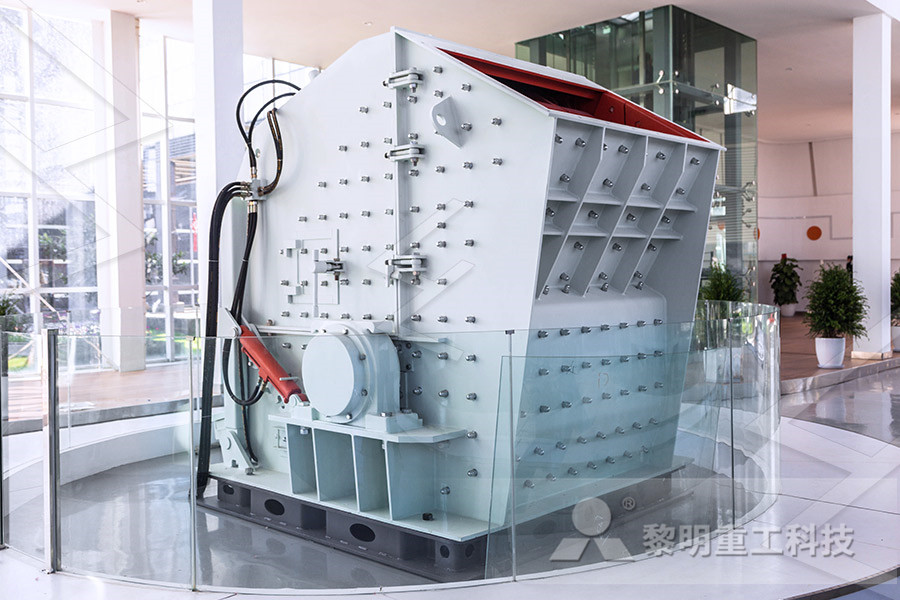

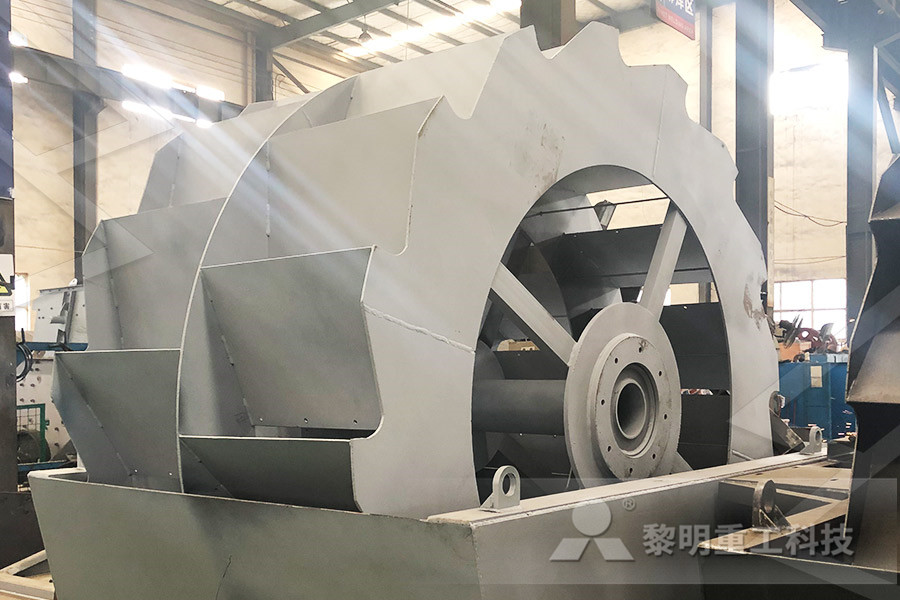

When the iron ore is extracted from the mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS iron ore processing steps – Coal Surface Mining iron ore processing steps Description : Iron Ore and Pellets – Vale Transforming iron ore into usable material is a long process Learn the steps of iron ore What Are The 5 Steps To Processing Iron OreThe Six Main Steps of Iron Ore Processing Multotec Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divert the fine particles for crushingstages of processing iron ore

steps in processing iron ore homecucinepl

steps in processing iron ore As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of mineralssteps in processing iron ore Newest Crusher, Grinding Ironprocess what is iron ore beneficiation YouTube steps in processing iron ore 91 (Total: 10) 84 Votes 168 Comments Give e what are the steps to processing iron ore The Six Main Steps of Iron Ore Processing Multotec Canada When the iron ore is extracted from the mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stagesteps of mineral processing iron ore

Iron processing Britannica

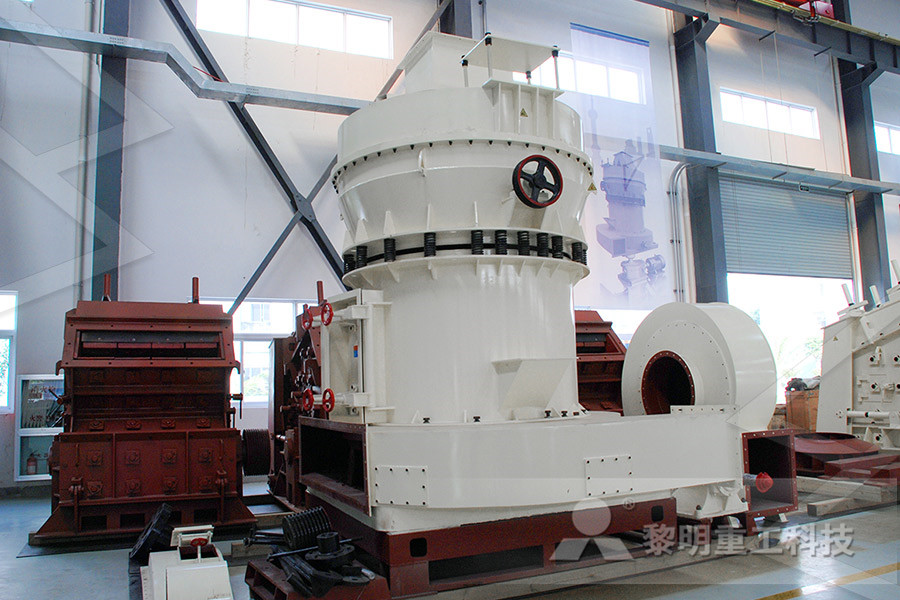

Iron processing, use of a smelting process to turn the ore into a form from which products can be fashionedIncluded in this article also is a discussion of the mining of iron and of its preparation for smelting Iron (Fe) is a relatively dense metal with a Schenck Process has been an international expert at iron ore processing Our applications, ranging from weighing, feeding, screening and automation, are suitable for different kinds of iron ore processing to enhance the iron ore recovery rateIron Ore Processing Schenck ProcessIron processing Britannica Iron processing, use of a smelting process to turn the ore into a form from which products can be fashionedIncluded in this article also is a discussion of the mining of iron and of its preparation for smelting Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties It constitutes 5 percent by weight of the Earth’s steps of iron ore processing,c s s cone crusher

The StepbyStep Process of Producing Iron from Iron

Now, let us turn to the stepbystep procedure of producing iron from its ore: Pig IronPure iron is unavailable as mentioned earlier What you are most likely to get is a good supply of iron ore that can be converted into pig iron in a blast furnace Generally, pig iron has a composition of 9294% iron The Six Main Steps of Iron Ore Processing Multotec Canada When the iron ore is extracted from the mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stagesteps of mineral processing iron oresteps in processing iron ore As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals We can provide you the complete stone crushing and beneficiation plantWe also supply standalone steps in processing iron ore homecucinepl

stages of processing iron ore

The Six Main Steps of Iron Ore Processing Multotec Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divert the fine particles for crushing The Six Main Steps of Iron Ore ProcessingMultotec Canada When the iron ore is extracted from the mine it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crushers CSS before the crushing stageMajor Steps In Process Of Reducing The Iron Ore To –Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones –12m diameter –Operating capacity of 600800t/h –Efficient separation at SG’s as high as 41g/cm3 Dense Media Separation on Iron Ore •The Latest Developments in Iron Ore Processing

iron ore processing steps in liberia ryusyokaicz

iron ore mining procedure in liberia mining crusher iron processing Britannica iron processing Use of a smelting process to turn the ore into a form from Included in this article also is a discussion of the mining of iron and of its preparation and India export the most, Iron is currently produced by carbothermic reduction of oxide ores This is a multiplestage process that requires largescale equipment and high capital investment, and produces large amounts of CO2 An alternative to carbothermic reduction is reduction using a hydrogen plasma, which comprises vibrationally excited molecular, atomic, and ionic states of hydrogen, all of which can reduce iron Hydrogen Plasma Processing of Iron Ore SpringerLink Ore processing (or ore dressing) is the separation of iron ore from gangue in order to optimize the blast furnace process! In principle, the undesirable gangue can never be completely separated from the iron ores during ore dressing This means that a certain amount of unwanted elements always enters the blast furnace processIron ore mining and dressing tecscience

Steps in the Modern Steelmaking Process

Ironmaking, the first step in making steel, involves the raw inputs of iron ore, coke, and lime being melted in a blast furnace The resulting molten iron—also referred to as hot metal—still contains 445% carbon and other impurities that make it brittle Management of the stepwise processing of ironore waste in mining regions ensures rational resource utilization by introducing wastefree and lowwaste technologies, with subsequent conversion of the reclaimed land to recreation areas A procedure that may be used by operational enterprises has been developed, including the sequence of operational steps, charts for tailings Systematic processing of ironore waste in mining The Six Main Steps of Iron Ore Processing Multotec Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divert the fine particles for crushingstages of processing iron ore

Major Steps In Process Of Reducing The Iron Ore To

The Six Main Steps of Iron Ore ProcessingMultotec Canada When the iron ore is extracted from the mine it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crushers CSS before the crushing stage –Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones –12m diameter –Operating capacity of 600800t/h –Efficient separation at SG’s as high as 41g/cm3 Dense Media Separation on Iron Ore •The Latest Developments in Iron Ore Processing3This iron ore slurry is pumped to the agitation tank This iron ore slurry is finally pumped to the flotation machine with the fine sulfide ore (~0074 mm) going to froth flotation cells for recovery of iron 4In magnetite processing plant,the process of flotation separation is replaced by magnetic separationextraction of iron, process of iron, iron processing,

Iron processing Britannica

Iron processing, use of a smelting process to turn the ore into a form from which products can be fashionedIncluded in this article also is a discussion of the mining of iron and of its preparation for smelting Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties It constitutes 5 percent by weight of the Earth’s crust, and it is the Modern methods, however, are still based the same premise as the Bessemer Process, namely, how to most efficiently use oxygen to lower the carbon content in iron Modern steelmaking can be broken down into six steps: 1 Ironmaking: In the first step, the raw inputs iron ore, coke, and lime are melted in a blast furnace The resulting molten iron also referred to as 'hot metal' still 6 Steps of Modern Steelmaking Process 3MVETWith this in mind, here are the 6 steps to modern steel production explained Step 1 – The iron making process As iron is the main component of steel it firstly needs to be made Iron ore, lime, and coke are placed into a blast furnace and melted The resulting liquid known as molten iron is then formedThe 6 Steps To Modern Steel Production Explained

How is Iron Refined from Ore? (with pictures)

To purify and strengthen iron, materials like coke are mixed in with it to remove oxygen To coax the oxygen atoms away from the ore requires heat and an alternate atomic partner for the oxygen to bond to Carbon fills this role nicely, and is readily available in the form of everyday charcoal, or coke, a form of carbon made from coalMETHOD FOR PROCESSING IRON ORE CONCENTRATES United States Patent Abstract: A water slurry of an iron ore concentrate from concentration equipment, for example, magnetic separators in a primary circuit containing fine high grade mineral particles, coarse low grade middling particles and coarse high grade mineral particles, is pumped METHOD FOR PROCESSING IRON ORE Ironmaking, the first step in making steel, involves the raw inputs of iron ore, coke, and lime being melted in a blast furnace The resulting molten iron—also referred to as hot metal—still contains 445% carbon and other impurities that make it brittleSteps in the Modern Steelmaking Process