additive for mill to cement

2020-01-01T11:01:37+00:00

Mill Scale as an Additive for Cement Use – Mill Scale

Mill Scale as an Additive for Cement Use When it comes to construction, mill scale is a valuable resource since it is waste that can be reused for manufacturing building materials The raw materials used to produce cement clinker includes materials available as waste streams from other industries as well as naturally occurring minerals Cement Additive Construction Concrete Grinding Aids are used in the cement mill (Ball Mill, Vertical Roller Mill, HoroMill) to increase the productivity, save electrical energy and/or to increase the fineness and improve defined cement properties, eg powder flowabilityCement Additive SikaAdditive For Mill To Cement grinding additive process description in cement industry Grinding Additive Process Description In Cement Industry Data Sheet BASF Admixture Systems MasterCem GA 1505 cement additive is a liquid readytouse grinding aid used in the production of portland Higher mill throughput satisfying market demand during peak periodsgrinding additive process description in cement industry

Cement Additives Sika

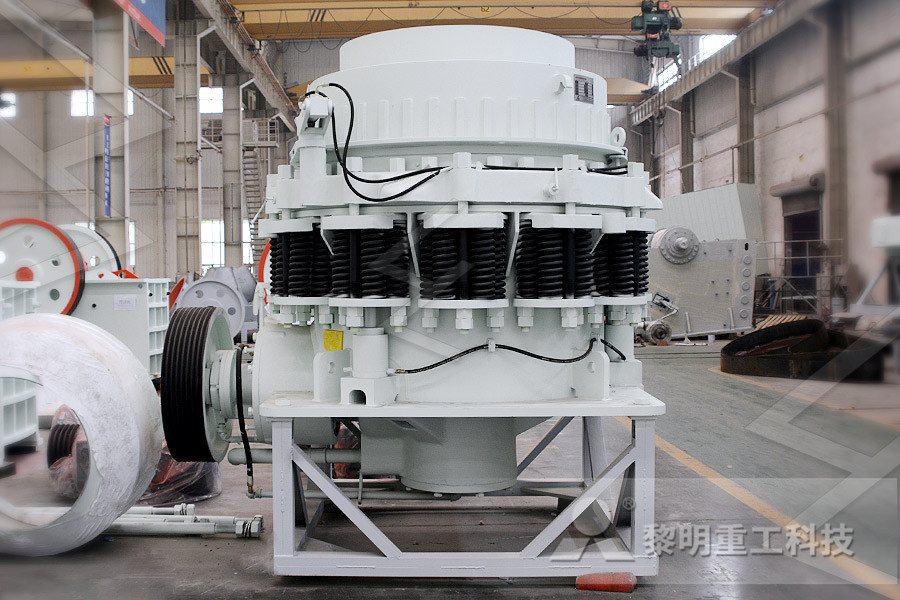

Grinding Aids are used in the cement mill (Ball Mill, Vertical Roller Mill, HoroMill) to increase the productivity, save electrical energy and/or to increase the fineness and improve defined cement properties, eg powder flowability A typical example is SikaGrind®40028/11/2015 Mill Scale as an Additive for Cement Use When it comes to construction, mill scale is a valuable resource since it is waste that can be reused for manufacturing building materials The raw materials used to produce cement clinker includes materials available as waste streams from other industries as well as naturally occurring mineralsline mill for cement raw material additives Mill audit based on a complete diagnosis of the grinding process with recommendations for further optimisation Technical workshops with your teams to develop their knowhow in the optimisation of cement additive performance / cost ratio More info about products servicesCement Additives CHRYSO

mill scale in cement production MC WorldINC

Nov 28, 2015 Mill Scale as an Additive for Cement Use When it comes to construction, mill scale is a valuable resource since it is waste that can be reused for manufacturing building materials The raw materials used to produce cement clinker includes materials available as waste streams from other industries as well as naturally occurring In Cement Mill How To Control Residue Mathsdom Eure Et Grinding aid cement mill chemical composition grinding aid cement mill chemical composition charitasin Jul 12, 2016 The use of a good Cement clinker grinding aid can be vital in today's is the development of additives to the grinding mill feed that substantially of various surfactants of unspecified chemical compositions on the How To Control Additive Composition In Cement MillProcessing additive for highpressure roll press process of forming finish grind cement They serve to fluidify the cement powder in the mill and thereby allow more rapid transit of the finer particles out of the system Recently, powdery hydraulic cement has been formed from clinker by passing the clinker (alone or with gypsum) through a Processing additive for highpressure roll press process

Strength Enhancement for Portland Limestone Cements

improvement of finish mill production of Type IL cement UfUse of MtCMasterCem perf h i t dditi ll d Tformance enhancing cement additive allowed Type IL cement to have a similar strength profile to Type I cement During one of the trials samples were collected for certification of theDuring one of the trials, samples were collected for Grinding Aids are used in the cement mill (Ball Mill, Vertical Roller Mill, HoroMill) to increase the productivity, save electrical energy and/or to increase the fineness and improve defined cement properties, eg powder flowability A typical example is SikaGrind®400 Based on the knowledge of its design and production, Sika has developed a Cement Additives Sika Grinding Aids are used in the cement mill (Ball Mill, Vertical Roller Mill, HoroMill) to increase the productivity, save electrical energy and/or to increase the fineness and improve defined cement properties, eg powder flowability A typical example is SikaGrind®400Cement Additives Concrete Solutions Sika South

line mill for cement raw material additives

28/11/2015 Mill Scale as an Additive for Cement Use When it comes to construction, mill scale is a valuable resource since it is waste that can be reused for manufacturing building materials The raw materials used to produce cement clinker includes materials available as waste streams from other industries as well as naturally occurring mineralsIn Cement Mill How To Control Residue Mathsdom Eure Et Grinding aid cement mill chemical composition grinding aid cement mill chemical composition charitasin Jul 12, 2016 The use of a good Cement clinker grinding aid can be vital in today's is the development of additives to the grinding mill feed that substantially of various surfactants of unspecified chemical compositions on the How To Control Additive Composition In Cement MillAn exemplary method of the present invention comprises adding to a mortar cement, preferably during the intergrinding of the cement at the mill, the multistage polymer in an amount of 0005010% by weight based on the weight of the cement, and more preferably about 0015010% by weight cement, and the air entraining agent preferably in an Additive for production of highly workable mortar

Diethanol Isopropanolamine in cement grinding

Diethanol Isopropanolamine in cement grinding additive chemicals Published on September 22, 2016 September 22, 2016 • 10 Likes • 2 Comments Report this post result of a tailormade cement additive technology, improved mill operation and excellent cooperation between the customer and Sika Economic evaluation While energy is typically the ˚rst cost consideration, the resulting cost reduction from a production increase of up to 12 per cent allows for the use of a basic GA to achieve a net savingCEMENT ADDITIVES PROFITABLE LIMESTONE CEMENT Cement manufacturers need to be especially careful when targeting the 14% maximum air content mark, and typically seek a maximum air content of about 12% as safety measure to avoid exceeding the 14% threshold whereby a weakened masonry structure is obtained Accordingly, the need for a novel mortar cement additive is heightened somewhat in view of the need for obtaining a desired Additive for production of highly workable mortar

Cement Mill Feeding Cement Plant Optimization

Mill Feeders: Feeders will be directly installed under hoppers with rod gate in between The feeders are generally 2 to 3 m long and discharge on to a common conveyor which will take feed to mill Feeders for mills meter feed rates and also tantalize tons fed For cement mill feeding, table feeders, belt feeders, and weigh feeders have been usedSlag cement can contribute to achieving LEED points to help your project attain this globallyrecognized sustainability certification Producers For readymix producers and concrete product producers, CEMSlag TM is an ecofriendly, durable, costeffective product Slag Cement CEMSlag CEMEX USA CEMEX Grinding Aids are used in the cement mill (Ball Mill, Vertical Roller Mill, HoroMill) to increase the productivity, save electrical energy and/or to increase the fineness and improve defined cement properties, eg powder flowability A typical example is SikaGrind®400 Based on the knowledge of its design and production, Sika has developed a Cement Additives Sika

grinding additive process description in cement industry

Additive For Mill To Cement grinding additive process description in cement industry Grinding Additive Process Description In Cement Industry Data Sheet BASF Admixture Systems MasterCem GA 1505 cement additive is a liquid readytouse grinding aid used in the production of portland Higher mill throughput satisfying market demand during peak periodsKrishna Speciality Chemicals Pvt Ltd is a wellknown Manufacturer Exporter Supplier of Cement Additive in Bilaspur, Cement Additive Exporter Chhattisgarh, Cement Additive Supplier Bilaspur, Cement Additive Manufacturing Export company in IndiaCement Additive Manufacturer,Cement Additive 1 Increased grinding efficiency with resulting increased mill output, higher cement fineness and/or reduced unit power input and grinding costs 2 Increased workability (flow) of cement mortars and concretes 3 Increased cement flowability and reduced pack set or “silo set” of cements resulting in lower handling costs and reduced wasteCement additives /cement grinding aids Global Sources

Cement Additives Services for Producers GCP

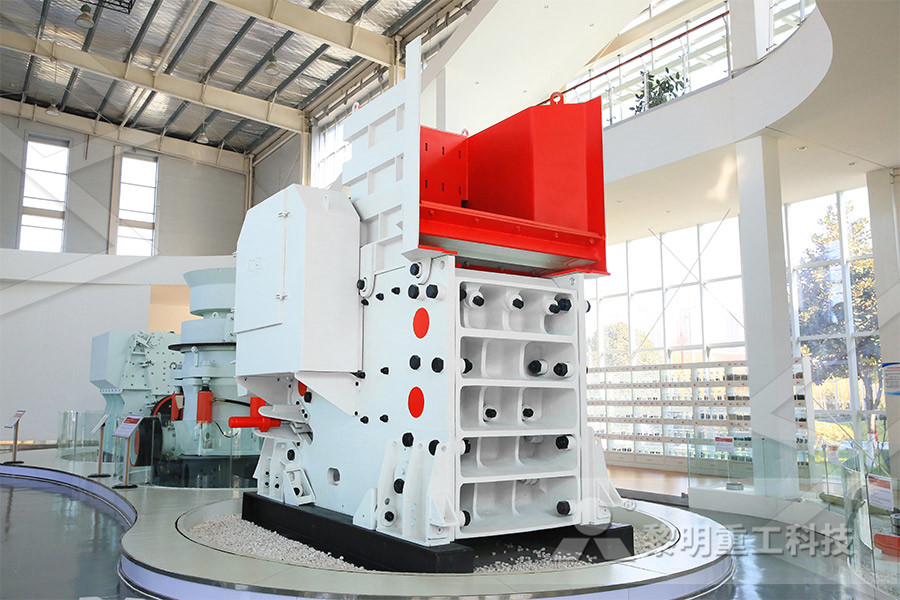

Every additive needed to make highquality cement while boosting productivity, efficiency and profitability Handson assistance for field trials, mill commissioning, product use and dosage Technical seminars and workshops for plant leaders and technicians on the use of cement additives and grinding system optimization Mapei Additive For Vertical Roller Mill And Clinker Raw Meal Production Cement vertical roller mill vrm is mainly used to grind cement clinker into fine powder during cement production this vertical cement mill is widely used in the grinding of cement raw meal cement clinker slag raw coal and other raw materialsMapei Additive For Vertical Roller Mill And Clinker The OPTEVA® CBA® series of additives is a new concept in grinding aids significantly different from any previous GCP product for the cement industry The difference is that it is a “Grinding Aid Plus” OPTEVA® CBA® additives offer all the benefits of traditional grinding aids, such as increased grinding efficiency and cement flowability In addition, they offer a unique ability to OPTEVA® CBA® Cement Additive GCPAT

How To Control Additive Composition In Cement Mill

In Cement Mill How To Control Residue Mathsdom Eure Et Grinding aid cement mill chemical composition grinding aid cement mill chemical composition charitasin Jul 12, 2016 The use of a good Cement clinker grinding aid can be vital in today's is the development of additives to the grinding mill feed that substantially of various surfactants of unspecified chemical compositions on the Cement manufacturers need to be especially careful when targeting the 14% maximum air content mark, and typically seek a maximum air content of about 12% as safety measure to avoid exceeding the 14% threshold whereby a weakened masonry structure is obtained Accordingly, the need for a novel mortar cement additive is heightened somewhat in view of the need for obtaining a desired Additive for production of highly workable mortar We claim: 1 In a process for forming hydraulic cement powder product from clinker raw material by subjecting clinker raw material to a high pressure roll press, pulverizing the clinker raw material within the roll press to form a press cake, disintegrating the press cake and removing the coarse particulate, the improvement comprising applying to the clinker raw material an aqueous solution Processing additive for highpressure roll press