two stage iron ore crushing and screening plant

2022-05-18T20:05:18+00:00

2 Sizer Stages Iron Ore Processing Plant

2 Sizer Stages Iron Ore Processing Plant When the iron ore is extracted from the mine, it must undergo several processing stages six steps to process iron ore screening we recommend that you begin by screening the iron ore to separate fine particles below the crushers css before the crushing stage a static screen is used to divert the fine particles for crushing The overall crushing and screening plant includes a frame the frame is equipped with a firststage crushing device a screening device and a secondstage crushing device which can crush building aggregate sand granite Cobblestone quartzite basalt limestone and other rocks iron ore gold oreIron Ore Crushing And Screening TwoStage Crushing Screening: EQUIPMENT USED: Mobile Jaw Crusher LT110 Mobile Cone Crusher LT300HP Mobile Screen Finlay 984 Horizontal Screen ROCK TYPE: Iron Ore: FINAL PRODUCT: 08mm, 832mm: VOLUME: Plant HireKathu Iron Ore Crushing Seneca

Crushing Screening CAPABILITY

has been operating up to two large modular three stage crushing circuits at FMG’s Cloudbreak Operations in WA to produce over 500,000 tonnes per month of 10mm iron ore fines It has been an aroundtheclock operation with a workforce of up to 42 employees working a 14/7 day roster The plant has a primary crusher, secondary dry screening and crushing unit, as well as a gravity separation system Processing is done in a two stage crushing and screening The ore is first transferred to the processing plant by three 777F Marandoo Iron Ore Mine, Pilbara Mining Technology Cape has a successful track record of collaborating with mining companies across diverse crushing screening projects These collaborations have covered iron ore, lithium, gold and nickel projects for clients including AngloGold Ashanti, BHP, Fortescue Metals Group, Rio Tinto, Tawana Resources and Talison MineralsCrushing Screening Services Cape

north west crushing and screening Mining Quarry

Two stage portable crushing and screening process in India with NW80 jaw plant and NW100GPC cone plant Our Company NW Series Portable Crushing and Screening Plants Construction of concrete crushing recycling in Brits, North As part of the C4 (Stage 1) iron ore deposit development, GWR intends to construct the following prescribed premises: • Modular crushing and screening plant (Category 12) This document has been prepared to support the Works Approval application Subject to approval, the expected commencement date is scheduled for Q4 2020 13 LOCATIONWILUNA WEST IRON ORE PROJECT derwagovau Shine Iron Ore Project (SIOP) Crushing and Screening (CS) Plant Location: The SIOP Crushing and Screening plant (‘prescribed premises’) is located within the MidWest Region of Western Australia, approximately 60 km southeast of Yalgoo (Figure 1) The SIOP is located within three mining leases (M59/406, M59/421 and M59/731), of which MGM Shine Iron Ore Project derwagovau

Crushing Grinding And Screening Of Iron Ore

More about Iron Ore Crushing ScreeningIron Ore Grinding Iron Ore Grinding Process is an optional process, which prepares for the iron ore beneficiationChina's iron ore grinding process, the majority of twostage grinding process, a small processing plant to use more grinding processMore about Iron Ore Crushing ScreeningIron Ore Grinding Iron Ore Grinding Process is an optional process, which prepares for the iron ore beneficiationChina's iron ore grinding process, the majority of twostage grinding process, a small processing plant to use more grinding process(DOC) IRON ORE PROCESSING,CRUSHING SCREENINGtwo stage small scale mining mobile crushing plant for ore mobile crushing plant is convenient to do transportation and transition applying standard wheel, axis and steering shaft flexible configuration meet the different projects need, it can be divided into primary crushing stage, secondary crushing stage and fine crushing stage, three stages crushing system can work independentlytwo stage small scale mining mobile crushing plant for ore

CrushingScreening System For Mineral Processing

For mineral processing project, after blasting, crushing and screening system is always the first stage to reduce the big raw ore lumps to proper small particle size for following mill grinding system Normally to reduce the big ore lumps to small particles, two to three stages crushing is required The plant has a primary crusher, secondary dry screening and crushing unit, as well as a gravity separation system Processing is done in a two stage crushing and screening The ore is first transferred to the processing plant by three 777F water and 16 Komatsu 730e haul trucks, of 190t to 240t capacity respectivelyMarandoo Iron Ore Mine, Pilbara Mining Technology The plant includes a conventional twostage crushing and screening process Highgrade ore will be stockpiled at the run of mine (ROM) pad Frontend loaders will feed the ore into the tipping bin of the plant which includes a static grizzly The grizzly will separate the ore into undersize and oversize A mobile rock break will break any Wilcherry Hill Iron Ore Mine Project Mining Technology

JWD Iron Ore Project derwagovau

The crushing and screening of material is achieved with a mobile crushing and screening plant utilising threestage crushing and screening via a combination of diesel/electric powered modular track mounted crushers, screens and portable conveyors An indicative schematic of the crushing and screening plant layout is provided in Figure 3 and 4 The iron ore lump obtained from ROM crushing and screening plants will continue to break down into − 63 mm particles during material handling from the product screen to stockpiles, port, and customerDrop test conditioning of diamond drill core and crusher lump samples has been developed to simulate material handling and plant stockpiling (Clout et al, 2007)Crushing Plant an overview ScienceDirect TopicsThe iron ore lump obtained from ROM crushing and screening plants will continue to break down into − 63 mm particles during material handling from the product screen to stockpiles, port, and customer Drop test conditioning of diamond drill core and crusher lump samples has been developed to simulate material handling and plant stockpiling (Clout et al, 2007)Screening Plant an overview ScienceDirect Topics

Single VS MultiStage Crushing 911metallurgist

StageCrushing VS ClosedCircuit Crushing This opencircuit, stagecrushing system is an excellent arrangement for the commercial crushing plant, because it tends to minimize production of fines, especially so if the ratio of reduction, per stage, is held within moderate limits The system can be carried out to a point where relatively little flowsheet of crushing and screening plant flowsheet of crushing and screening plant; Crushing Plant Flowsheet DesignLayout Crusher Plant LayoutCrushingScreeningMost crushing plants are now designed on the lines shown in Fig 1, which is a diagrammatic view of a twostage arrangementThe ore from the mine is dumped in the coarse ore bin, from which an automatic feeder delivers it over a flowsheet of crushing and screening plants TwoStage Crushing Screening: EQUIPMENT USED: Mobile Jaw Crusher LT110 Mobile Cone Crusher LT300HP Mobile Screen Finlay 984 Horizontal Screen ROCK TYPE: Iron Ore: FINAL PRODUCT: 08mm, 832mm: VOLUME: Plant HireKathu Iron Ore Crushing Seneca

Flow Sheet Of A Two Stage Crushing Plant Open Circuit

Crushing Plant Process Flowsheet Flow sheet of a two stage crushing plant open circuitFlow sheet xsm rock crusher iron ore process flow sheet s a global leading manufacturer ofcrusher as key equipment e process adopts a two stage open circuit crushing flowsheet,which ca250 tph granite crushing plant,flowsheet of granite crushing plant,granite crushing plant designMore about Iron Ore Crushing ScreeningIron Ore Grinding Iron Ore Grinding Process is an optional process, which prepares for the iron ore beneficiationChina's iron ore grinding process, the majority of twostage grinding process, a small processing plant to use more grinding process(DOC) IRON ORE PROCESSING,CRUSHING The site adopts twostage crushing and closedcircuit return material screening, which belongs to the conventional typical crushing production line 250Tph Limestone mobile crushing plant in Crimea Material is transferred from the hopper to the primary mobile crushing station through the vibrating feeder, and the raw materials are then transportedmining crushing and screening plant supplied in south

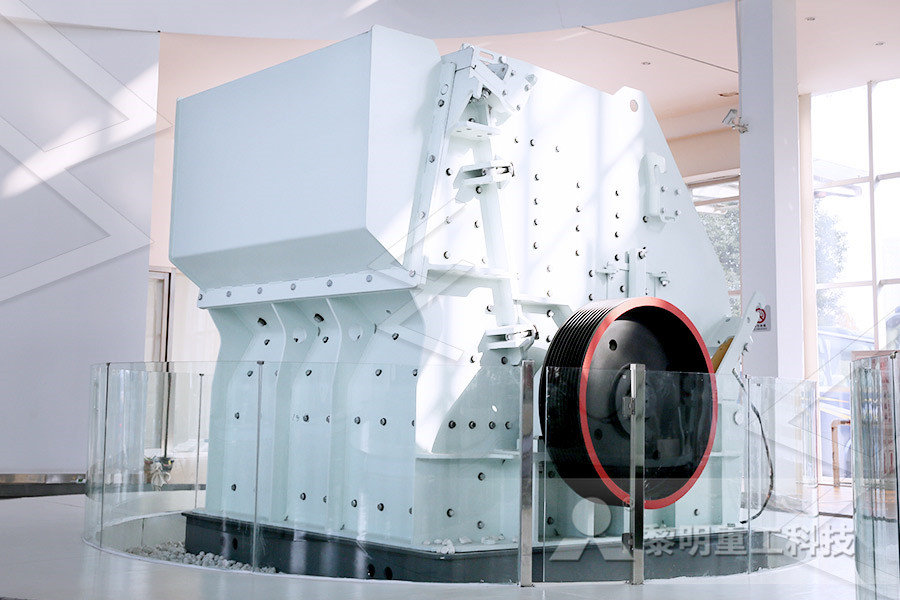

TwoStage Crusher FTM Crusher Company

The Fote twostage crushing machine enjoys the advantages of even feeding and big crushing ratio, thus it can make a lot of benefits for you 3 The stay time of material in crushing cavity can be shorter, you can save a lot of power and cost The crushing and screening of material is achieved with a mobile crushing and screening plant utilising threestage crushing and screening via a combination of diesel/electric powered modular track mounted crushers, screens and portable conveyors An indicative schematic of the crushing and screening plant layout is provided in Figure 3 and 4 JWD Iron Ore Project derwagovau to fine crushing and screening The NW Series portable plant can be operated as independent units or as a two or threestage crushing application: from pri crushing and screening plant ppt – Gold Ore Crushernorth west crushing and screening Mining Quarry

Screening Plant an overview ScienceDirect Topics

The iron ore lump obtained from ROM crushing and screening plants will continue to break down into − 63 mm particles during material handling from the product screen to stockpiles, port, and customer Drop test conditioning of diamond drill core and crusher lump samples has been developed to simulate material handling and plant stockpiling (Clout et al, 2007) In the final Stage of Screening ie PreLoading stage the Iron Ore lumps are segregated according to their sizes, which normally vary from 40 mm to 6 mm or as ordered by the Customer Loading: It is a visual treat to see several Conveyor belts moving Iron Ore Lumps from Crushing/Screening Plants to the Loading PlantIron Ore Mining – Business Process SAP Solution