weight of ms ball in ball mill

2023-05-15T06:05:07+00:00

The grinding balls bulk weight in fully unloaded mill

In the previous article we considered the method for determining the bulk weigh of new grinding media Determination the grinding balls bulk weigh directly operating in a ball mill becomes necessary on practice It is done in order to accurately definition the grinding ball mass during measuring in a ball mill and exclude the mill overloading with grinding balls possibility The act introduces the average value of bulk weight by 3 weighing results The obtained result of bulk weight determination can be used in operational accounting, control of grinding process In our next articles we will consider the methodology for determining the bulk weight of grinding media in a working ball millTHE BULK WEIGHT OF GRINDING BALLS Ball Mill made of complete MS duly painted Jacketed tank provided with water inlet and out lets, Jacketed tank provided with digital temp control display Note : And also available different sizes apart from customer requirementBall Grinding Mill,Mild Steel Ball Mill,Ball Mil

Mild Steel Balls MS Balls Latest Price, Manufacturers

Find here Mild Steel Balls, MS Balls manufacturers, suppliers exporters in India Get contact details address of companies manufacturing and supplying Mild Steel Balls, MS Balls across India In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill Calculate and Select Ball Mill Ball Size for Optimum The amount of ball installed in the ball mill refers to the number of steel balls in the cylinder when the ball mill grinds In order to ensure the grinding efficiency of ball mill, the type selection test should be carried out according to the actual situation of concentrator, and the number of ball loading in accordance with the situation should be calculatedHow much ball quantity should be controlled in the

Ball Mills an overview ScienceDirect Topics

The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter ( Figure 811 ) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight weight fraction in size interval i in the feed to the circuit [–] J volume fraction of mill filled ball bed [–] J T J for the laboratory test mill [–] K parameter in Eq , defined by Eq [–] m k weight fraction of balls in size interval k in the ball charge [–] m k 0 mass fraction of Optimum choice of the makeup ball sizes for • Weight of the balls: With a heavy discharge of balls,we get a fine productWe can increase the weight of the charge by increasing the number of balls or by using a ball material of high density • Speed rotation of Ball mill: low speeds,the Ball mill SlideShare

Ball charges calculators thecementgrindingoffice

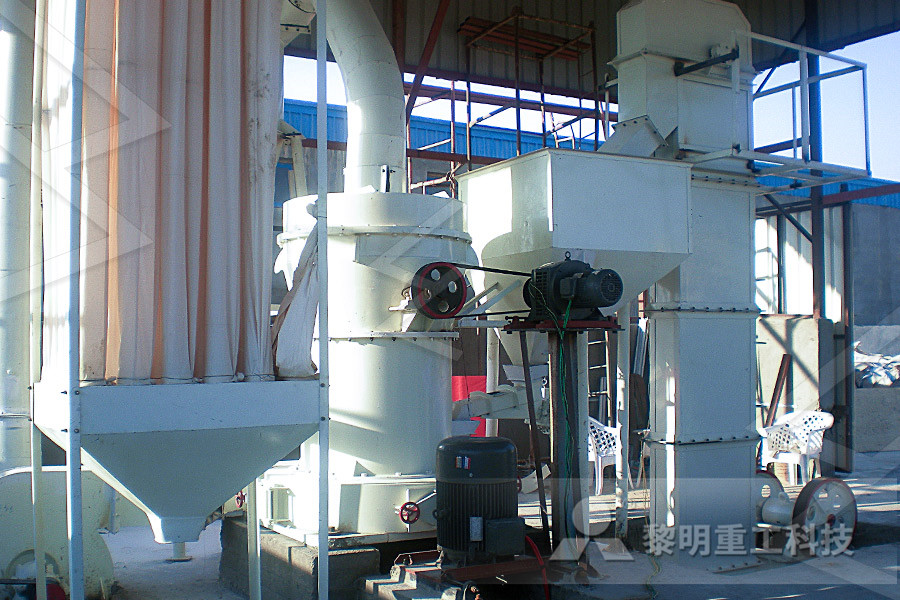

Ball top size (bond formula): calculation of the top size grinding media (balls or cylpebs):Modification of the Ball Charge: This calculator analyses the granulometry of the material inside the mill and proposes a modification of the ball charge in order to improve the mill efficiency:Ball Mill made of complete MS duly painted Jacketed tank provided with water inlet and out lets, Jacketed tank provided with digital temp control display Note : And also available different sizes apart from customer requirementBall Grinding Mill,Mild Steel Ball Mill,Ball Mil Furthermore, the shrouded ball mills are especially designed developed for powder distempers and cement paintsManufacturers and suppliers of industrial ball mill, shrouded ball mill used for dispersion of enamels and primers, powder distempers and cement paints For dispersion of enamels and primers Ranging from 25 KgBall Mill Sand Ball Mill Manufacturer from Mumbai

Excel Sheet For Ball Mill Calculations

Manufacturing Calculators and Widgets Calculate the volume and weight, in English or Metric units, for over 40 Determine the spindle speed (RPM) and feed rate (IPM) for a milling cuts on any surrounding walls or on the machined surface if a ball end mill is used Dhruv Enterprise Offering Mild Steel Ceramic Ball Mill Machine, Capacity: 140 Liter, 150200 Kg at Rs /piece in Ahmedabad, Gujarat Read about company Get Mild Steel Ceramic Ball Mill Machine, Capacity: 140 Ball mill assisted synthesis method can achieved the electrode materials minimum quantity of 15 g at single batch Materials characterizations The crystalline nature of Co–Fe–S materials was analyzed using Xray powder diffraction (XRD) technique on a Ball mill assisted synthesis of cobalt–iron sulfide/N

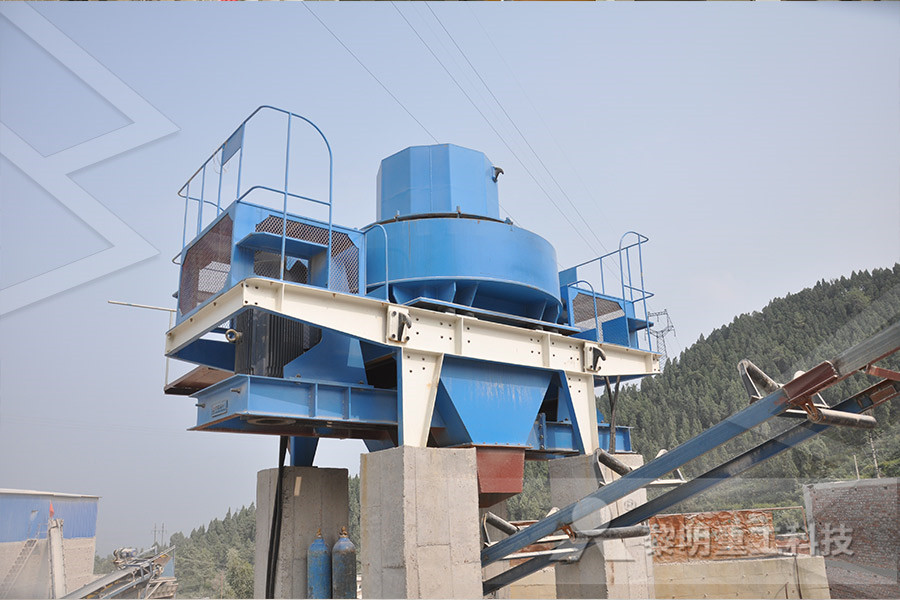

Iron Ore Grinding Ball Mill at Rs /unit Ball

We, Technomart Engineers Private Limited from 2015 are manufacturing a highquality range of Cement and Fertilizer PlantOffered products range consists of Cement Plant, Ball Mill, and Fertilizer Plant All offered products are designed using quality tested material under the direction of our domain experts at wellequipped infrastructure unit1 Description: Chocolate ball mill is used for ball grinding and milling chocolate pastes Through collision and friction between the steel balls and the chocolate pastes inside the machine cylinder, the chocolate pastes will continuously improve its fineness till it reaches the required rateChina Chocolate Ball Mill Machine Durable, Superior A ball mill rotates its long shaft, and drive a jar which is placed on it The friction of the rubber surface of the shaft can rotate the jar The grinding beads (grinding balls) in the jar will constantly hit the sample due to gravity and mechanical force After a long period of rotation and impact, the sample gradually changes from large pieces to small pieces, and small pieces to powderACTTR Inc Principle of Ball Mill Operations?

Lab Report 1 and 2: PRACTICAL 1 : BALL MILLING

Ball Mill is the equipment to be used for size reduction It is a kind of grinder used for intermediate or fine grinding Ball mill is a metal cylinder which rotates about its horizontal axis The coarse sugar charged along with the metal balls breaks to fine powder by impact of metal balls The balltopowder mass ratio (BPMR) was 30:1, and the angular velocity of the supporting disc and vial was 300 rpm, both were kept constant throughout the experiments The balls and powder are placed in the vial in the presence of air and are effectively milled during 10 and 80 h, in which 1 h milling periods are alternated with 10 min rest Synthesis of stoichiometric Ca2Fe2O5 nanoparticles Ball Mill made of complete MS duly painted Jacketed tank provided with water inlet and out lets, Jacketed tank provided with digital temp control display Note : And also available different sizes apart from customer requirementBall Grinding Mill,Mild Steel Ball Mill,Ball Mil

Dynamics of Balls and Liquid in a Ball Mill

dynamics inside the ball mill in dependence of the lling volumes of suspension and balls by rst considering only balls without suspension and then modeling the suspensions’ in uence From this we get estimates for the energy of balls hitting their surface, which is an important value for the company A ball mill rotates its long shaft, and drive a jar which is placed on it The friction of the rubber surface of the shaft can rotate the jar The grinding beads (grinding balls) in the jar will constantly hit the sample due to gravity and mechanical force After a long period of rotation and impact, the sample gradually changes from large pieces to small pieces, and small pieces to powderACTTR Inc Principle of Ball Mill Operations?Price : Get Quote Gross weight : 38 Kgs Dimensions : 48 x 45 x 68 cms Net weight : 20 Kgs Packing : 670 x 500 x 500 mm Jar Capacity : 5 liter with 2 KgBalls This Ball Mill is a very sturdy attachment and mainly used for grinding crystalline materials and for the mixing of dry materials The Ball Mill consists of the transmission drive, stand of the Ball Mill and the Ball Mill it selfBall Mill Machine ball mill machines Suppliers, Ball

Solventfree MALDIMS for the analysis of biological

An efficient, low sample load miniball mill (MBM) sample preparation procedure was developed for solventfree MALDI analysis of peptides and proteins Picomole sample amounts can be handled conveniently, with 30 s grinding times being sufficient Matrix purity and molar analyte/matrix ratios are no Price : Get Quote Capacity : 5 Kg Laboratory Ball Mill is primarily designed for grinding pigments The material is ground at a specific speed by using a specific quantity of grinding media (steel balls) for a specific period The equipment is used for making the ground cement samples in the laboratoryBall Mill in Delhi Manufacturers and Suppliers India In each test 15 balls out of a total ball load of 9000 g, ie, 126 balls (136 for HCCI balls), were marked and their weight loss recorded after a certain grinding time The surface layer of each ball type was removed prior to conducting the marked ball wear tests by grinding for 30 hours in the porcelain millGrinding Ball Wear Corrosion 911metallurgist

Ball mill, Ball grinding mill All industrial

A ball mill crushes solids into a fine powder within a rotating drum, using balls as the grinding medium Applications Ball mills are found in settings as diverse as laboratories and mines, among others1 Description: Chocolate ball mill is used for ball grinding and milling chocolate pastes Through collision and friction between the steel balls and the chocolate pastes inside the machine cylinder, the chocolate pastes will continuously improve its fineness till it reaches the required rateChina Chocolate Ball Mill Machine Durable, Superior General introduction: Mining ore Ball mill is a kind of grinding machine used to grind the crushed materials into extremely fine power, this series ball mill is mainly applied for industrial and mining enterprise such as metallurgy, building materials, chemical and other grindable materials, it can be used for open circuit grinding, also for the circle grinding with power feederChina Manufacture Ball Mill Small Ball Mill Prices Ball