vibratory feeder lubrication

2020-02-11T16:02:02+00:00

Lubrication and Maintenance Schedule Vibrating Grizzly

Lubrication and Maintenance Schedule Vibrating Grizzly Feeder (Type HF Vibrating Unit) Warning: Lockout/tagout power before performing any lubrication, maintenance, adjustments or repairs! 08/02 Page 1 of 4 Maintenance Daily Startup Daily Shutdown Weekly Monthly Annually As Req’d Notes: CHECK OIL LEVEL AT PETCOCKS ON EACH SIDE OF VIBRATING UNIT The amount of oil required for the SZ feeder varies depending on the model: 3 Oil grade should be correct During the daily maintenance, we recommend the same lubricants (N100 industrial gear oil) for SZ feeders as for SC cone crusher lubrication system in tropical and subtropical regions For the main motor, we recommend grease: 4 Special notesReMinderSZ Vibrating Feeder Daily Lubrication Oil Lossinweight vibratory feeder in pharmaceutical design Coperion KTron Feeders are used in high accuracy dispersion for both tablet press lubrication and addition of powders to the coating process Tablet press lubrication and powder dispersing for tablet coating are both processes which can be significantly enhanced using Coperion KTron pharmaceutical feedersTablet Coating and Press Lubrication – Coperion

ELECTROMAGNETIC VIBRATORY FEEDER INSTRUCTION

than 70 to 72 dba maximum If the noise level increases or hammering occurs switch off the Feeder immediately and refer to the trouble shooting section 90 INSTALLATION MAINTENANCE These Vibratory Feeders have no motors, shafts or other moving parts that require lubrication, therefore maintenance is a minimum requirementTips to Extend Life of Jeffrey Rader Vibratory Feeders and lubrication, along with replacement of OEM wear parts, help your Jeffrey Rader vibrating feeder maintain optimal performance and extend the life of your equipment If you would like to schedule a service visit, order new OEM parts, or discuss a rebuild of your vibrating feeder Tips to Extend Life of Jeffrey Rader Vibratory Feeders No routine maintenance or lubrication is required, except that any accumulation of foreign matter should be periodically removed from between the traytiebar assembly and the body, and from between the body and the mounting surface, to prevent restriction of movement of the vibratory elements IMPORTANT NOTE: Special Trays and AttachmentsInstallation, Operation and Maintenance Instructions

Vibratory Feeders – Coperion

The K3 vibratory feeders have a modular design and are available in both a standard design and a hygienic easy clean design Vibratory feeders are ideal for gentle handling of a wide range of bulk solid materials, especially fragile ingredients and problem lubrication schedule and quantity required for your vibrator Replacement Martin CD Series Do NOT attempt to replace bearings on a Martin vibrator In the event of a failure contact Martin Engineering at 8005442947 OR Eriez ERV Bearing must be replaced exclusively on the work bench by qualified personnel with the power supply deactivatedInstallation, Operation and Maintenance Instructions LUBRICATION Bearings should be lubricated approximately every 200 hours of operation with gun grease suitable for roller bearings To reach grease fittings, first shut down the unit, lockout tag out, then remove plugs from the two access holes on the end of Installation, Operation and Maintenance Instructions

ReMinderSZ Vibrating Feeder Daily Lubrication Oil

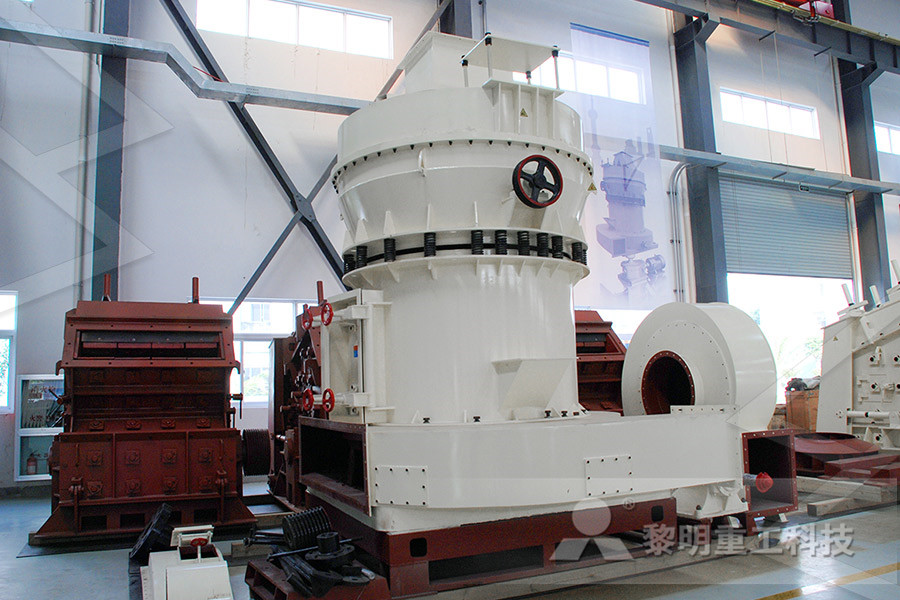

The amount of oil required for the SZ feeder varies depending on the model: 3 Oil grade should be correct During the daily maintenance, we recommend the same lubricants (N100 industrial gear oil) for SZ feeders as for SC cone crusher lubrication system in tropical and subtropical regions For the main motor, we recommend grease: 4 Special notesThe lubrication processes are vital to the assembly of the bushings, thus over lubricated bushings are irreversibly damaged and must be scrapped accordingly Design Bulk bushings are dumped from the prefeed system onto several metering conveyors and then into a standard vibratory parts feederVibratory Feeder Bowl System StromagTips to Extend Life of Jeffrey Rader Vibratory Feeders and lubrication, along with replacement of OEM wear parts, help your Jeffrey Rader vibrating feeder maintain optimal performance and extend the life of your equipment If you would like to schedule a service visit, order new OEM parts, or discuss a rebuild of your vibrating feeder Tips to Extend Life of Jeffrey Rader Vibratory Feeders

Installation, Operation and Maintenance Instructions

TABLE 1 LUBRICATION GUIDE Suggested Lubrication Period in Weeks Hours run 251 to 501 to 751 to 1001 to per day 500 rpm 750 rpm 1000 rpm 1500 rpm 812 10 7 5 16 7 5 4 2 24 5 3 2 1 Operation and Maintenance (cont) applications However, extra protection is necessary if bearing is subjected to excessive moisture, dust, or corrosive vapor than 70 to 72 dba maximum If the noise level increases or hammering occurs switch off the Feeder immediately and refer to the trouble shooting section 90 INSTALLATION MAINTENANCE These Vibratory Feeders have no motors, shafts or other moving parts that require lubrication, therefore maintenance is a minimum requirementELECTROMAGNETIC VIBRATORY FEEDER INSTRUCTION Featuring a unique, new patentpending drive system, the new Coperion KTron K3 Vibratory Feeder is a highly accurate feeding solution for the gentle handling of a wide variety of freeflowing materials, including friable products, abrasive products, products with nonuniform shapes and glass fibersVibratory Feeders – Coperion

Installation, Operation and Maintenance Instructions

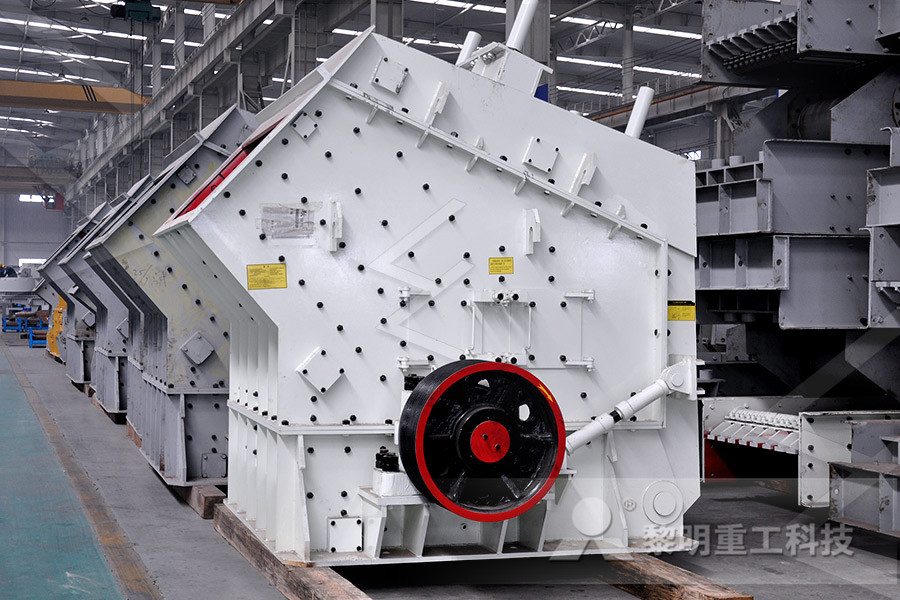

VIBRATORY FEEDER 5 Installation Mounting This HiVi model should be mounted on a flat surface, fastened with bolts of proper size Use lock washers under the bolt heads FIGURE 1 Model 46C Electrical Connections NOTE: The Eriez Vibratory Feeder is designed to be operated from an AC source It cannot be operated from a DC source Vibratory Feeder Models 10A, 20A, 30A, 40A, 45A, 50A And 55A Installation, Operation and Maintenance Instructions ERIEZ MAGNETICS HEADQUARTERS: 2200 ASBURY ROAD, ERIE, PA 16506–1402 USA WORLD AUTHORITY IN SEPARATION TECHNOLOGIESInstallation, Operation and Maintenance InstructionsThe expanding applications of vibratory feeders for controlling the flow of bulk materials, and their adaptation for processing requirements, have developed a considerable interest in stockpiling and reclaim systems The general design of these units consists of a material transporting trough (or platform) driven by a vibratory force systemVibrating Feeder Design Stockpile Reclaim

What to Expect for Maintenance of Pneumatic

As my incredibly knowledgeable associate Mike Stratis provided a posting about accessories to consider for your installation of a pneumatic vibrator, I thought I would provide a followup piece to discuss what to expect AFTER the install As with any equipment, pneumatic vibrators and their supporting accessories do require some love, attention, lubrication and cleaning from time to time The amount of oil required for the SZ feeder varies depending on the model: 3 Oil grade should be correct During the daily maintenance, we recommend the same lubricants (N100 industrial gear oil) for SZ feeders as for SC cone crusher lubrication system in tropical and subtropical regions For the main motor, we recommend grease: 4 Special notesReMinderSZ Vibrating Feeder Daily Lubrication Oil than 70 to 72 dba maximum If the noise level increases or hammering occurs switch off the Feeder immediately and refer to the trouble shooting section 90 INSTALLATION MAINTENANCE These Vibratory Feeders have no motors, shafts or other moving parts that require lubrication, therefore maintenance is a minimum requirementELECTROMAGNETIC VIBRATORY FEEDER INSTRUCTION

Tips to Extend Life of Jeffrey Rader Vibratory Feeders

Tips to Extend Life of Jeffrey Rader Vibratory Feeders and lubrication, along with replacement of OEM wear parts, help your Jeffrey Rader vibrating feeder maintain optimal performance and extend the life of your equipment If you would like to schedule a service visit, order new OEM parts, or discuss a rebuild of your vibrating feeder Performance Feeder Features • Dusttight and maintenancefree drive units: Feeders have no mechanical parts to wear out, such as cams, eccentrics, belts and bearings thus eliminating the need for lubrication • Twomass, springconnected, subresonant tuned: All movement is confined to the heavyduty leaf springsSyntron® HeavyDuty Feeders ASGCOCustom made vibratory feeder with Italvibras vibrating motor Flexible Drive Arrangement: The electromechanical drive may be positioned either above or below on the side or at the rear of the pan Vibroveyor feeders are available in a variety of sizes ranging from 50 to 2,000 tons per hourVibrating Feeder RR Fisher Co Ltd

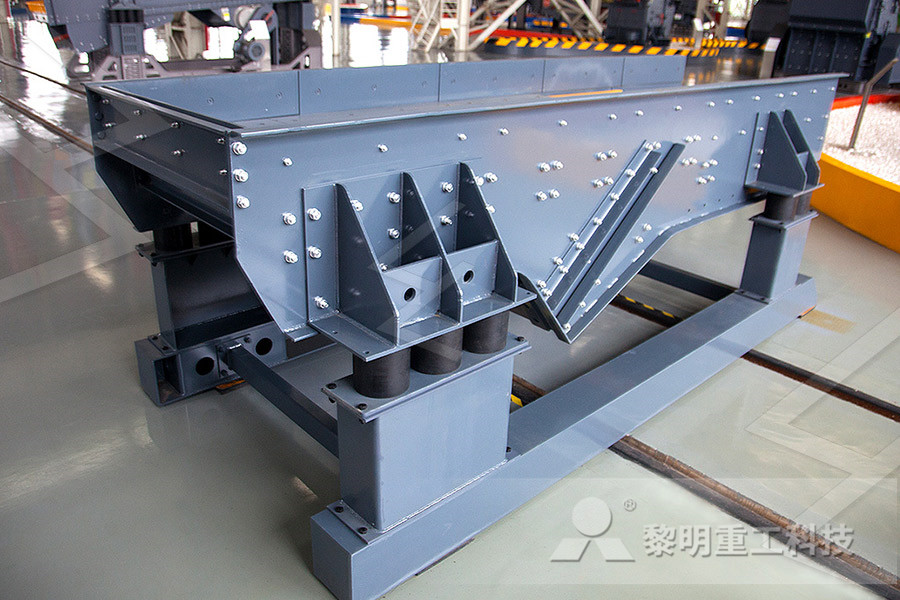

Building Material Linear Vibratory Feeder

5 Widely application, alloy screen cell feeder can used for conveying wear and corrosive materials, sealing structure feeder can used for high pollution and easy to dust material 6 Feeder with features like small overall size, light weight, simple structure, no need lubrication and VIBRATORY FEEDER 5 Installation Mounting This HiVi model should be mounted on a flat surface, fastened with bolts of proper size Use lock washers under the bolt heads FIGURE 1 Model 46C Electrical Connections NOTE: The Eriez Vibratory Feeder is designed to be operated from an AC source It cannot be operated from a DC sourceInstallation, Operation and Maintenance InstructionsManufacturer of Vibratory Equipment Vibratory Pan Feeder, Vibro Pan Feeder, Vibrating Screens and Grizzly Vibro Feeder offered by Metofabrik, Belgaum, Karnataka Bearings and Lubrication For vibrator motors custom made with particular geometry, specially designed to support both high radial and axial loads are used Vibratory Equipment Vibratory Pan Feeder

Vibratory Feeder Bowl System Stromag

The lubrication processes are vital to the assembly of the bushings, thus over lubricated bushings are irreversibly damaged and must be scrapped accordingly Design Bulk bushings are dumped from the prefeed system onto several metering conveyors and then into a standard vibratory parts feederFeeder System Monthly Inspection Checklists* Carry out the following inspections on a monthly basis, regardless of whether the equipment has been run or not Check if lubrication is needed or that lubrication has been performed as described in Chapter 6 of the operation manual Check that all fasteners, screws, bolts, etc are secure and tightCentrifugal Feeder Maintenance Guide Rotary