effect of the mill speed on cyclone efficiency

2023-06-11T14:06:45+00:00

effect of the mill speed on cyclone efficiency

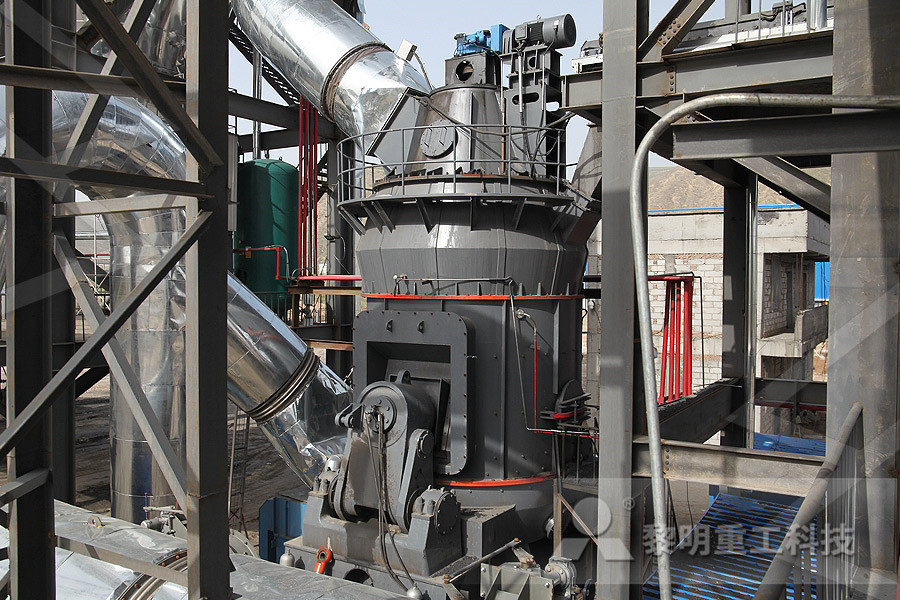

Effect Effect Of Shales On Coal Crusher Efficiency Effect Of The Mill Speed On Cyclone Efficiency Effect Of The Mill Speed On Cyclone Efficiency We are a largescale manufacturer specialiing in producing various mining machines including different types of sand and gravel equipment milling equipment mineral processing equipment and Moreeffect of the mill speed on cyclone efficiency The pump speed is modulated to maintain the level in the mill discharge hopper in a system, if the ore hardness or throughput increases, the achievable grind size increases however, in this system, the cyclone cut point, dictated by the selected cyclone feed density does not change MoreHigh Speed Cyclone Grinding Principle THE INFLUENCE OF MILL SPEED AND PULP DENSITY ON THE GRINDING EFFICIENCY 89 Pilot plant description The milling pilot plant consists of two containers mounted on top of each other (see Figures 1 and 2) The bottom container holds the mill, the drive train, rollers and the hightension cabinet The feed boxes (fine and coarse feed) are built into theThe influence of mill speed and pulp density on the

Closed circuit ball mill – Basics revisited ScienceDirect

However, the effect of each is difficult to quantify in practice as these two parameters are usually interrelated Based on experience acquired over the years and the investigative work conducted by FC Bond, it was established that the optimum circulating load for a closed ball mill – cyclone The higher the column height, the finer the separation particle size However, if the height of the column exceeds a certain limit, it will lose its effect due to the increase in the feed pressure loss 6 Hydrocyclone Cone Angle The cone angle has an important influence on the classification efficiency of the hydrocyclone6 Factors Affecting Hydrocyclone Efficiency The effect of dust concentration on the performance of the dust collector is due to the increase of the friction loss between the dust particles, the decrease of the rotational speed of the air flow, and the decrease of the centrifugal force, so that the resistance and efficiency are reducedFactors that affect the performance of cyclone dust

Factors Affecting Ball Mill Grinding Efficiency

The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed Tools for Increased Cyclone Efficiency: Series Cyclone Arrangements • Can provide higher collection efficiency for a limited inlet velocity because of the cumulative efficiency: 90% @ 5 micron + 90% @ 5 micron= 99% @ 5 micron • May provide for redundancy in the event of system upsetsBasic Cyclone Design ASME Met SectionHammer Mill With Cyclone And Blower Locally made hammer mill and its typical construction much tedium and timeconsuming labour various types of small the abrasive disc huller has a row of carborundum discs in a chamber grain subjected to a force responds in three distinct stages theHammer Mill With Cyclone And Blower C O C O A H

DESIGN OF CYCLONE AND STUDY OF ITS PERFORMANCE

present investigation the characteristics of flour mill cyclone are studied for various flow rates (inlet velocities) and its effect on performance parameters like pressure drop and efficiency are studied Cyclone is designed with two symmetrical tangential inlets and a single tangential outlet at the barrel top area where impeller is mountedeffect of mill speed in the cyclone efficiency 47 4816 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industryeffect of mill speed in the cyclone efficiency – The cyclone design called the ‘1D3D’ was first introduced by Texas AM University Collection efficiency improvements brought about by design modifications were confirmed through USDA ginning lab tests , Modified 1D3D cyclones are widely used in agricultural processing, such as by the US cotton ginning industry Fig 1 shows dimensions in cm of the modified 1D3D cyclones that were Could cyclone performance improve with reduced

AMIT 145: Lesson 2 Classifying Cyclones – Mining Mill

The efficiency of a classifying cyclone is typically measured by the slope of the partition curve plotted on the basis of the probability of a particle reporting to the underflow stream versus particle size A more direct efficiency measurement from the partition curve is the imperfection value (I): The pump speed is modulated to maintain the level in the mill discharge hopper In a system, if the ore hardness or throughput increases, the achievable grind size increases However, in this system, the cyclone cut point, dictated by the selected cyclone feed density does not change Instead the circulating load increasesCyclones Don’t Do Any Grinding Blog Orway The effect of dust concentration on the performance of the dust collector is due to the increase of the friction loss between the dust particles, the decrease of the rotational speed of the air flow, and the decrease of the centrifugal force, so that the resistance and efficiency are reducedFactors that affect the performance of cyclone dust

Basic Cyclone Design ASME Met Section

Tools for Increased Cyclone Efficiency: Series Cyclone Arrangements • Can provide higher collection efficiency for a limited inlet velocity because of the cumulative efficiency: 90% @ 5 micron + 90% @ 5 micron= 99% @ 5 micron • May provide for redundancy in the event of system upsets the fiber cyclone Since the conventional system lack in efficiency of product, therefore new technique is required to improve the conventional method Based on the commercial performance evaluation of the system in certain palm oil mills show that, the amount of cracked mixture for wet separation is about 6080 percentENHANCING THE EFFICIENCY PROCESS FOR circulating loads are still encountered following experimentation with the mill density, the effect of reducing mill speed should be assessed The rate of abrasion grinding may be slower than the rate of impact breakage and the two can be brought into equilibrium by decreasing the impact force available through lowering the mill speedAN OVERVIEW OF SINGLE STAGE AUTOGENOUS AND

AMIT 145: Lesson 3 Dense Medium Separation –

DM Cyclone Operation The reason for the near horizontal position is that, in the vertical position, the gravitational pull on the dense medium results in a slumping of the medium toward the apex, which pinches the air core Under a ‘slumping’ condition, the separation efficiency would be very sensitive to inlet pressure and medium viscosity present investigation the characteristics of flour mill cyclone are studied for various flow rates (inlet velocities) and its effect on performance parameters like pressure drop and efficiency are studied Cyclone is designed with two symmetrical tangential inlets and a single tangential outlet at the barrel top area where impeller is mountedDESIGN OF CYCLONE AND STUDY OF ITS PERFORMANCE effect of mill speed in the cyclone efficiency 47 4816 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industryeffect of mill speed in the cyclone efficiency –

AMIT 145: Lesson 2 Classifying Cyclones – Mining Mill

The efficiency of a classifying cyclone is typically measured by the slope of the partition curve plotted on the basis of the probability of a particle reporting to the underflow stream versus particle size A more direct efficiency measurement from the partition curve is the imperfection value (I): the mill power applied to coarse material, ie, larger than the reference size, therefore: CPR (t/h) = mill power applied to coarse material (kW) × mill grinding rate of coarse material (t/kWh) The circuit classification system efficiency (CSE) is the percentage of the mill solid material content that is coarser than the reference sizeBall mill optimization Improving conveyor performance The effect of circulating load and classification efficiency on the performance of ball mill circuits is compared to the effect on HPGR circuits The fundamentals of grinding behavior are also discussed in order to explain the difference î INTRODUCTION Currently, closed ball mill cyclone circuits are an industry standardEffect of circulating load and classification efficiency

ENHANCING THE EFFICIENCY PROCESS FOR

the fiber cyclone Since the conventional system lack in efficiency of product, therefore new technique is required to improve the conventional method Based on the commercial performance evaluation of the system in certain palm oil mills show that, the amount of cracked mixture for wet separation is about 6080 percent circulating loads are still encountered following experimentation with the mill density, the effect of reducing mill speed should be assessed The rate of abrasion grinding may be slower than the rate of impact breakage and the two can be brought into equilibrium by decreasing the impact force available through lowering the mill speedAN OVERVIEW OF SINGLE STAGE AUTOGENOUS AND Cyclone separators are utilised in many applications due to their low cost, simple design and high efficiency Cyclone separators require no bags or filters and require only low maintenance Dirty Filters A typical application would include a saw mill Saw mills generate a lot of dust which must be extracted from the millCyclone Separator Working Principle (Dust Separator

AMIT 145: Lesson 3 Dense Medium Separation –

DM Cyclone Operation The reason for the near horizontal position is that, in the vertical position, the gravitational pull on the dense medium results in a slumping of the medium toward the apex, which pinches the air core Under a ‘slumping’ condition, the separation efficiency would be very sensitive to inlet pressure and medium viscosity Raw Bond Model This is a SAG or AG mill plus ball mill model that estimates the specific energy consumption (E SAG) using the 1979 Barratt equation and the classical Bond work index equation including Rowland efficiency factorsThe model allows a manual calibration factor on both equations (CF SAG and CF ball, respectively)This formula usually gives higher total circuit specific energy Model:Raw Bond/Barratt SAB SABC Model