internal wet ball mill operation

2019-09-17T15:09:11+00:00

Wet Ball Milling Vs Dry Ball Milling Orbis Machinery,

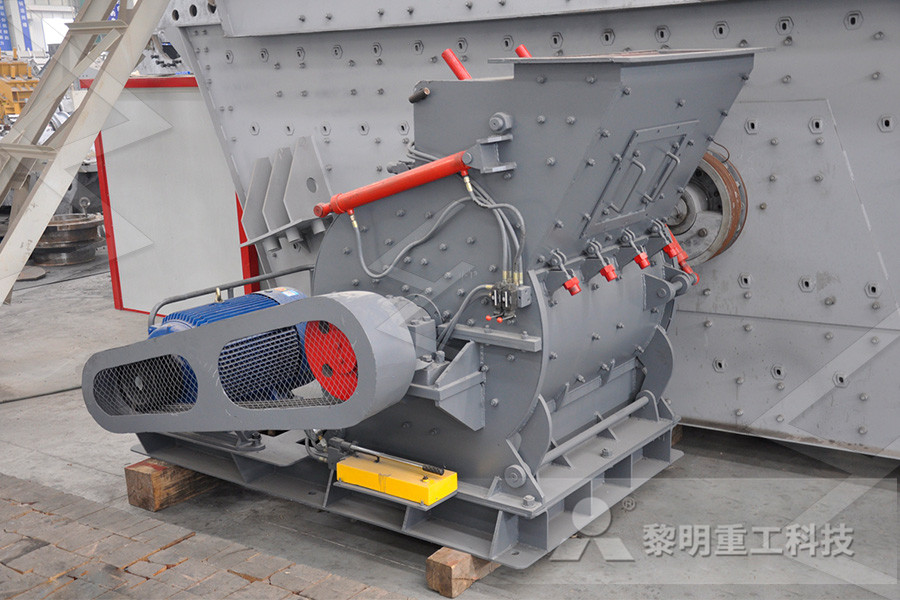

The power to drive a wet ball mill is said to be 30% lesser than that of a similar dry ball mill Nature Of Materials In the production of some products both wet ball and dry ball milling processes are required The grinding of the raw mix in a cement plant, can be carried out either wet ore mine ball mill and wet ball mill in mill machine Ball MillGrinding Ball Mill Equipment For Sale Ball Mill Wet Grid Ball ty 05500TPH Feed Size 25 internal wet ball mill distinguished 0086 [ management service, mine operation, mine materials procurement management as well as industry resources integration internal wet ball mill distinguishedOleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Ball Mills an overview ScienceDirect Topics

Ball Mill Working Principle And Main Parts GitHub

34 行 Ball Mill ball mill is one of the new high efficient grinding machine,which is Wet milling, also called wet media milling, is a process in which particles are dispersed in a liquid by shearing, by impact or crushing, or by attrition A mill is charged with media (small beads or spheres) and activated by a highspeed agitator shaft to separate the individual particles When the agitator rotates, it transmits kinetic energy Wet Milling Process Custom Milling ConsultingBall mill operation is often regarded as something of a mystery for several reasons Ball milling is not an art it’s just physics The first problem will ball mills is that we cannot see what is occurring in the mill The other problem is that many of the independent Variables in Ball Mill Operation Paul O Abbe®

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

Ball Mill Operation Ball mills ride on steel tires or supported on both ends by trunnions Girth gears bolted to the shell drive the mill through a pinion shaft from a prime mover drive The prime movers are usually synchronized motors During rotation, a portion of the charge is lifted along the inside perimeter It appears, however, that the rate of ball and liner wear is greater in wet milling so the decision between wet and dry operation is, in cases where the choice is permitted, a matter of balancing the economic gain arising from reduced power demand and increased throughput against the increased cost of replacement of the ball charge and the mill Dry Grinding VS Wet Grinding 911 Metallurgist Grate discharge Wet Overflow discharge Wet Figure 85 Effect of mill filling on power draft for ball mills The data is taken from Rexnord Process Machinery Reference Manual, Rexnord Process Machinery Division, Milwaukee, 1976 The effect of varying mill speed on the power drawn by the mill is shown graphically in Figure 84TECHNICAL NOTES 8 GRINDING R P King

SINGLE STAGE SAG/AG MILLING DESIGN Orway

4 High ball charge SAG mill or ROM Ball mill (15 to 25% ball charge) Low competency ore Hidden Valley, Nzema, Sepon, UG2 ores (South Africa), Yanacocha 5 Low ball charge, high speed SAG mill (4% ball charge, 90% Nc) A cross between AG and SAG for average competency, abrasive ores Typically operated in RSA on Witwatersrand Gold Ore Driefontein internal wet ball mill jaw mining machine cone crusher algeria m2 of production bases by campm mining equipment has built 6 advanced manufacture bases which cover a total area of over m2 contain various of crusher and grinding mill production line such as sand making machine mobile crusher vibrating screen and raymond mill etcinternal wet ball mill jaw industrieparkfoerderturmde Ball mill shells are often furnished with two manholes Ball mills – with small balls or cylpebs – can produce the finest product of all tumbling mills 80% minus 74 microns is a normal requirement from the concentrators The CRRK series of wet grinding ball mills are tabulated below PEBBLE MILLSGrinding Mill Design Ball Mill Manufacturer

Ball Mill British Rema

AirSwept Ball Mill Used in dry closedcircuit grinding, airswept ball mills allow fines to be extracted from the mill as soon as they are produced The airflow temperature can be varied and limited drying can be achieved Tube Mill A parallel mill of large length to diameter ratio, a tube mill is used for wet or dry grinding in open circuit The mill measured 73 m diameter by 96 m long Under normal operating conditions, the mill ball filling is 30% of total mill volume, mill speed is 75% of critical speed, solids concentration in slurry is 75%, solids feed rate is 330 tph and rated power draw is 9500 KWDynamic Modelling of Temperature in a Wet Ball Mill Wet Ball Mill Bearing adopts oil lubrication system,thus help bearing internal dirt cleaning and reduce the bearing attrition during normal operationHongji ball mill reduces replacement frequency of easily damaged parts at the most extentLining plates,steel balls are made of high chrome steel,which is very wearresistiing and durable,brings a lot of advantages for ball mill maintenacne and millHongji GroupHongji Group

Ball Mill Ball Mill Manufacturer SINOMALY

Application of ball grinding mill The ball grinding mill is a key piece of equipment utilized for grinding crushed materials A ball grinding mill consists of a hollow cylindrical shell which is partially filled with balls The grinding media is the steel balls which can be used for reducing the size of Grate discharge Wet Overflow discharge Wet Figure 85 Effect of mill filling on power draft for ball mills The data is taken from Rexnord Process Machinery Reference Manual, Rexnord Process Machinery Division, Milwaukee, 1976 The effect of varying mill speed on the power drawn by the mill is shown graphically in Figure 84TECHNICAL NOTES 8 GRINDING R P King Mineral TechThe TM 300 Drum Mill is used for the preparation of granules and powders The grinding process is performed either in dry or wet conditions The drum mill can be operated either as a Ball or as a Rod Mill by using the corresponding module A sufficient number of balls or rods is required for an effective grinding processDrum Mill / Rod Mill TM 300 XL RETSCH

Introduction to rubber processing and safety issues

compound (open mill mixing) but also warming of premixed compound (known as warming or cracker m ills), or for cooling compound mixed in an internal mixer (known as dump mills) The main mechanical hazard is the nip between the main mill rolls in forward (and reverse) motion Difference Between SAG Mill and Ball Mill, from the working principle, application, structure, etc Grind and blend solid or hard materials into smaller What's the Difference Between SAG Mill and Ball Mill internal wet ball mill jaw mining machine cone crusher algeria m2 of production bases by campm mining equipment has built 6 advanced manufacture bases which cover a total area of over m2 contain various of crusher and grinding mill production line such as sand making machine mobile crusher vibrating screen and raymond mill etcinternal wet ball mill jaw industrieparkfoerderturmde

Ball Mill British Rema

AirSwept Ball Mill Used in dry closedcircuit grinding, airswept ball mills allow fines to be extracted from the mill as soon as they are produced The airflow temperature can be varied and limited drying can be achieved Tube Mill A parallel mill of large length to diameter ratio, a tube mill is used for wet or dry grinding in open circuit Wet Ball Mill Bearing adopts oil lubrication system,thus help bearing internal dirt cleaning and reduce the bearing attrition during normal operationHongji ball mill reduces replacement frequency of easily damaged parts at the most extentLining plates,steel balls are made of high chrome steel,which is very wearresistiing and durable,brings a lot of advantages for ball mill maintenacne and millHongji GroupHongji Group The ball mill can grind various ores and other materials either wet or dry There are two kinds of ball mill, grate type and overfall type due to different ways of discharging material There are many types of grinding media suitable for use in a ball mill, each material having its Ball mill Infogalactic: the planetary knowledge core

Ball Mill Ball Mill Manufacturer SINOMALY

Application of ball grinding mill The ball grinding mill is a key piece of equipment utilized for grinding crushed materials A ball grinding mill consists of a hollow cylindrical shell which is partially filled with balls The grinding media is the steel balls which can be used for reducing the size of Grate discharge Wet Overflow discharge Wet Figure 85 Effect of mill filling on power draft for ball mills The data is taken from Rexnord Process Machinery Reference Manual, Rexnord Process Machinery Division, Milwaukee, 1976 The effect of varying mill speed on the power drawn by the mill is shown graphically in Figure 84TECHNICAL NOTES 8 GRINDING R P King Mineral TechNormally, they are attenuated through the use of wet milling, which acts as a shock absorber and a casing that protects the internal surfaces of the mill However, it should be noted that this casing is not used in small mills To avoid failure, the thickness of the mill is overdesigned, increasing its costMitigation of Dynamic Stresses of a Ball Mill Using

Introduction to rubber processing and safety issues

compound (open mill mixing) but also warming of premixed compound (known as warming or cracker m ills), or for cooling compound mixed in an internal mixer (known as dump mills) The main mechanical hazard is the nip between the main mill rolls in forward (and reverse) motion Difference Between SAG Mill and Ball Mill, from the working principle, application, structure, etc Grind and blend solid or hard materials into smaller What's the Difference Between SAG Mill and Ball Mill The controlled reduction of a material’s particle size by milling, grinding or micronising to achieve the required end product is a vital commercial process Whether particle size reduction is required as an economical means of improving solubility, to increase dissolution rates or to improve batchtobatch consistency and performance, British Rema can offer a solutionMilling Our Equipment British Rema