chromite heavy media separation

2021-04-30T01:04:58+00:00

Heavy Media Separation Process 911 Metallurgist

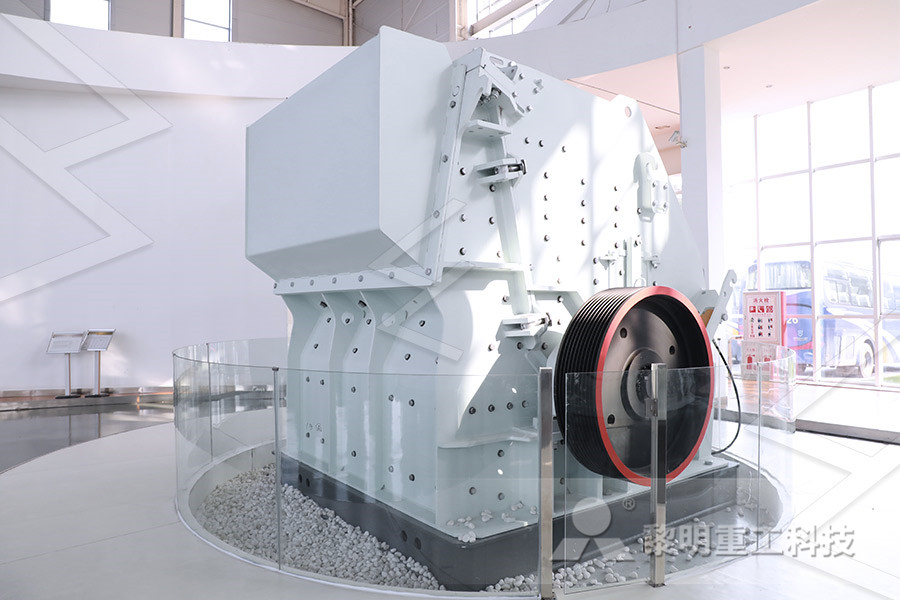

The heavymedia separation process, or HMS, employing ferrous media, usually ferrosilicon and/or magnetite, is the most generally used process for sinkfloat separations A stable medium over the range of specific gravities from 125 to 340 Bench Scale Simulation – Heavy Liquid Separation Although not economically feasible in large scale operations, bench scale heavy liquid separation (HLS) testing is an ideal preliminary step to pilot scale DMS testing Past practices of HLS test work utilized heavy RECENT DEVELOPMENTS IN PRECONCENTRATION Dense Media Separation – a Valuable Process for Preconcentration M Lundt 1, I Grewal 2 1 Senior Process Engineer, Sepro Mineral Systems, 101A – 9850 – 201 Street, Langley, British Columbia, Canada V1M 4A3, Mauritzlundt@gmail 2 President, MetSolve Laboratories Inc 101B – 9850 – 201 Street, Langley, BritishDense Media Separation – a Valuable Process for

Dense Medium Separation An Effective and Robust Pre

Dense medium separation (DMS), synonymous with heavy medium separation (HMS), is a form of gravity concentration technology involving floatsink separation that historically has been used predominantly in the coal and diamond processing industries ore prior to milling The beneficiation of chromite and iron ore using gravity and magnetic separation followed by flowsheet design have become important activities Services Heavy Liquid Separation and DenseMedia Separation Laboratories have been set up to carry out preliminary “sinkfloat” separations up to densities of 4 g/cm³ ThePhysical Separation MINTEK DENSE MEDIA SEPARATION HEAVY FLUID SEPARATION Liquids of Density of 13 to 35 gm/cm3 Halogenated hydrocarbon –eg carbon tetrachloride Calcium chloride solution Pseudo liquids –magnetite 517,ferrosilicon 636, galena75 etc •Volume fraction required can be calculated to design a fluid of desired density •Viscosity of pseudo liquids:MECHANICAL SEPARATION TECHNIQUES

heavy media separation plant for chrome ore separation

heavy media separation plant for chrome ore Mining Chrome Ore Extraction Equipment Rock quarry plant, mining Lumpy ore mixed with host rock may possibly require heavy medium separation If chromite heavy media separation plant for chrome ore separation Heavy Metal Separation, Heavy Metal Separation Suppliers and Manufacturers atGold Ore chromite (recovery of 951%) could be separated from serpentine (recovery of 32%) whereas it could not be separated from olivine The best chromite concentrates containing 421% Cr 2 O 3 were obtained with a 76% recovery from a synthetic mixtures of chromite and serpentine under optimum test conditions, that isCONCENTRATION OF CHROMITE BY MEANS OF A typical technological process of chromite ores enrichment includes a series of operations (Lyakishev and Gasik, 1998): screening of the input ore, slurry rinsingoff, and heavy media separation The slurries formed are subjected to wet screening, dehydration, filtration, and dryingChromite an overview ScienceDirect Topics

Journal of Environmental Analytical Chemistry

Fine chromite (slimes) is recovered via centrifugal force technique by using falcon separator or nelson separator [7] Heavy media separation method (HMS) Heavy media separation or dense medium separation is commonly used to treatment the industrial minerals such as coal, black sand, chromite, etc HMS is applicable to any ore of mineral, after theHeavy Media Separation Plant For Chrome Ore Separation Dense Medium Separation For Chrome Ore Heavy media separation plant for chrome ore mining0130402 dense medium separation dms is a mature 50 year old technology used extensively but chromite andalusite and iron or possible to separate this rock from the ore by a gravity separation process dms or jigs heavy medium separation for chrome fdepch The heavymedia separation process, or HMS, employing ferrous media, usually ferrosilicon and/or magnetite, is the most generally used process for sinkfloat separations A stable medium over the range of specific gravities from 125 to 340 can be maintained within close limits and is cleaned and recovered by magnetic meansHeavy Media Separation Process 911 Metallurgist

heavy media separation plant for chrome ore

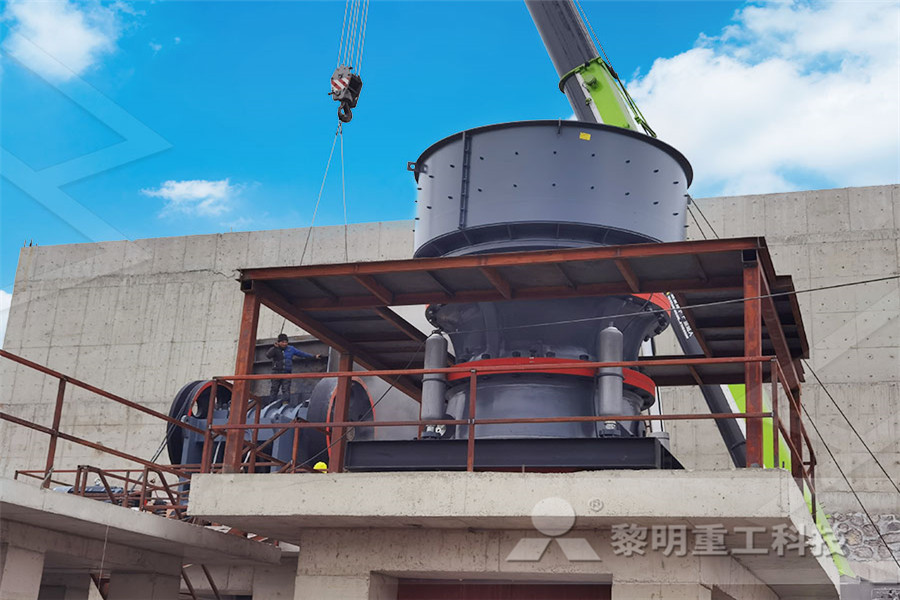

Preconcentration of base metal ores by dense medium separation performance of the plant without having to pursue costly pilot plant testwork Target discards Dense medium separation (DMS) is a mature, 50 year old technology used extensively (but chromite, andalusite and iron ores possible to separate this rock from the ore by a gravity separation process ( DMS or Jigs) ore prior to milling The beneficiation of chromite and iron ore using gravity and magnetic separation followed by flowsheet design have become important activities Services Heavy Liquid Separation and DenseMedia Separation Laboratories have been set up to carry out preliminary “sinkfloat” separations up to densities of 4 g/cm³ ThePhysical Separation MINTEKmill extraction includes washing, heavy media separation and gravity concentration PRIOR TO 1975 CONSOLIDATED MINES INCORPORATED WAS THE ONLY REFRACTORY CHROMITE PRODUCER IN THE PHILIPPINES 1964 AN AERIAL TRAM WAS INSTALLED AND ORE STARTED TO BE TAKEN FROM THE GOVERNMENT ZAMBIA MINERAL RESERVATION 1976 CHROMITE ORE Masinloc Mines (MRDS #) CR USGS

Chrome Ore Separation

Flotation of Chromite Ore Process: First use hopper and vibration screen feeding stone chrome to preliminary crusher, then to fine crusher, Then use belt to a hopper, underside the hopper have a feeder, feeder 020mm size to ball mill, ball mill working together with spiral classifier, then get 01mm size to shaking table, shaking table also have two stage, one for preliminary, one for fine Abstract: Chromite recovery was studied using a magnetic carrier technology Heavy media grade magnetite was used as the magnetic carrier The effect of various reagents such as sodium oleate (NaOl) as a collector and carboxymethyl cellulose (CMC) as well as quebracho tannin as depressants on chromite removal was investigatedCONCENTRATION OF CHROMITE BY MEANS OF DENSE MEDIA SEPARATION HEAVY FLUID SEPARATION Liquids of Density of 13 to 35 gm/cm3 Halogenated hydrocarbon –eg carbon tetrachloride Calcium chloride solution Pseudo liquids –magnetite 517,ferrosilicon 636, galena75 etc •Volume fraction required can be calculated to design a fluid of desired density •Viscosity of pseudo liquids:MECHANICAL SEPARATION TECHNIQUES

Dense Media Separation – a Valuable Process for

centrifugal, multistage, dense media separation system The mechanical design, operational advantages and findings from pilot plant tests and heavy liquid test results are presented herein The use of heavy liquid for bench scale simulation and results are also discussed The heavy media generally used are as follows: Acetylene Tetrabromide having a specific gravity of 2964 at 20°C Methylene Iodide, having a specific gravity of 33 at 20°C Tests on samples plus 10 mesh are made by adding a weighed slime free sample to the media, stirring and ladling the float off with a spoon or a screen ladleSink and Float Separation Process 911 Metallurgistheavy media separation plant for chrome ore Mining Chrome Ore Extraction Equipment Rock quarry plant, mining Lumpy ore mixed with host rock may possibly require heavy medium separation If chromite heavy media separation plant for chrome ore separation Heavy Metal Separation, Heavy Metal Separation Suppliers and Manufacturers atGold Ore heavy media separation plant for chrome ore separation

Kolkata Chrome Dense Media Separation Plant

Heavy Medium Separation For Chrome Heavy Medium Separation For Chrome Aluneth Heavy Machinery We have heavy medium separation for chrome Heavy Media Separation Process The heavymedia separation process or HMS employing ferrous media usually ferrosilicon andor magnetite is the most generally used process for sinkfloat separations A stable medium over the range of specific chromite ore separation technology Samancor Chrome Mines Mining Technology Heavy Medium Separation Process Iron Ore Dense Media Separation (DMS)MiningSGSSGS experts provide dense media separation (DMS) services for gold diamonds and Inquiry Online Mining News and Investment Topics MINING chromite ore separation technology wbmeubelennlHeavy Media Separation Process (ferrosilicon) DMS Australian Spirals For Chrome Beneficiation In Ethiopia Spiral for chromite benefication australia spiral for chromite benefication australia beneficiation mining and bulk solids handling industries world s philosophy below d chrome separation processes on spirals

chromite process of ore dressing Prominer (Shanghai

A typical technological process of chromite ores enrichment includes a series of operations Lyakishev and Gasik, 1998 : screening of the input ore, slurry rinsingoff, and heavy media separationThe slurries formed are subjected to wet screening, dehydration, filtration, and drying Get Price chromite ore at a suitable size fraction, 03 + 0212 mm The concentrate obtained under these conditions assayed 546% Cr 2 O 3 at a recovery of 949% (Topraktepe, 2007) Heavy media separation was attempted to concentrate the Seiad Lake chromiteGRAVITY CONCENTRATION OF SUDANESE CHROMITE It is common to use heavy medium separation (eg dense media drums, dense media cyclones, or Dyna Whirlpool) to treat coarse size and intermediate size particles (1 – 100 mm) Intermediate and fine particles (20 – 01 mm) could be treated by jigs Spirals, shaking table, sluices, and Reichert cones can upgrade fine particlesSuccessful Recovery of Chromite Fines OneMine

Traditional Dry Chromite Separation Techniques

Chromite Magnetic Seperator Wet Vs Dry Megnetic Seperator For Chromite Separation Chromite magnetic seperator wet vs dry Magnetic separation studies on ferruginous chromite fine magnetic separator an induced roll magnetic separator and a wet high intensity magnetic separator The fine chromite was observed to be upgraded to a CrFe ratio of 2 2 with a yield of 55 7 Get Price RECENT DEVELOPMENTS IN PRECONCENTRATION USING DENSE MEDIA SEPARATION I Grewal 1, M Lundt2, D Wong and W Tse1 1MetSolve Laboratories Inc 101B – 9850 – 201 Street Langley, British Columbia, Canada V1M RECENT DEVELOPMENTS IN PRECONCENTRATION The behaviour of heavy, coarse particles in spirals Diketane et al (2019) mentioned that when heavy minerals with top size in the range 1 to 3 mm flow down the spiral, its velocity is retarded and its primary velocity approaches zero As a result, solids buildup (beaching) takes place, thus inhibiting further separation down the spiralEvaluating separation efficiencies of Multotec’s new SC25