belt filter for iron fines

2019-01-16T05:01:01+00:00

Horizontal vacuum belt filter HVBF ANDRITZ

High extraction efficiencies are the key to profitability in most washing applications, whether it is for gold, uranium, phosphoric acid, copper, or alumina The horizontal vacuum belt filter can attain wash efficiencies of more than 998% as plug flow displacement and multistage countercurrent washing is utilized over the filtration area The continuously rotating filter screen is constantly cleaned by spray nozzles at one end and a scraper at the other, allowing fines to be collected in a catch basin beneath the belt In the standard system, fines are collected on a large woven wiremesh screen that periodically must be removed and cleaned, a process that requires stopping BeltFiltration System for Widely Used Underwater of water to provide frictionless belt movement WEAR STRIP AND WEAR BELT The concept of wear strips and wear belt for vacuum sealing was developed by DELKOR in 1976 and has since adopted by all major belt filter manufacturers around the world Wear strips are made from highly wear resistant, low friction material and are attached to the vacuum boxHORIzONTAL BELT FILTERS TENOVA

Belt Filter Press – PHOENIX Process Equipment

Belt Filter Press The PHOENIX Belt Filter Press dewaters slurries of prethickened solids from a pumpable liquid phase to a solid, conveyable, and stackable cake Over 30 years ago, PHOENIX belt presses were applied for dewatering thickened tailings resulting from mineral washing processes The bed of the iron ore fines formed on the dewatering screen can be thought of as a cake of fine and ultrafine mineral particles on a filter cloth The dewatering phenomenon is often quantified by the Laplace–Young equation, which relates the pressure necessary to drain a capillary to the surface tension, contact angle and a nominal Improved dewatering of iron ore fines by the use of iron rejects will end up disposed in a tailings dam [2] Tailings disposal and processing of iron fines have become crucial for environmental preservation and recovery of iron valuables, respectively, and therefore the processing of iron ore tailings and fines in the mining industry has grown in importance 7]POTENTIAL APPLICATIONS FOR DRY BENEFICIATION OF

Magnetic Filter – Permanent Magnets Ltd

Magnetic Filters are used for filtration of iron particles from products in liquid/slurry form They essentially used in chemical, food, pharma and oil industries They are also frequently used in hydraulic circuits in cooling systems The Filter Magnets are made This cake greatly increases the filter's ability to capture very small fines, in some cases down to 1 micron in size The use of pressure keeps the dirty coolant flowing through the filter for long filtration cycle times on the same section of media The Oberlin Filter can COOLANT FILTRATION Oberlin Filter The Tilden openpit iron mine – Michigan State University When the Empire and Tilden mines are producing concentrated iron ore pellets energy to convert ironbearing rock into marblesized pellets of concentrated ore In time, it is the cost of transporting the ore from the everdeepening pit bottom Iron ore concentrate (known as "filter cake") provides the ingredient for the cost of conversion of iron ore fines into filter cake

F1 Guidelines for Handling Aluminum Fines Generated

Fines and how they are generated During fabricating operations, aluminum fines may be generated by such activities as grinding, sawing, cutting, sanding or scratch brushing and at least some of them will be fine enough to be potentially explosible The term “dust” or “powder” is frequently used to describe such particles The bed of the iron ore fines formed on the dewatering screen can be thought of as a cake of fine and ultrafine mineral particles on a filter cloth The dewatering phenomenon is often quantified by the Laplace–Young equation, which relates the pressure necessary to drain a capillary to the surface tension, contact angle and a nominal Improved dewatering of iron ore fines by the use of Innovative Technique to generate saleable Iron Ore Fines from beneficiation plant Tailings Sauvick Mazumdar RaghavendraM Subhash Naik Dy COO, IOD, Goa Ass FEED TO CERAMIC FILTER CERAMIC FILTER MAG CONCENT RATE TRIPPER CONVEYOR BELT COVERED SHED Conclusion With the synergy from the above study, further inhouse and external R D study on Innovative Technique to generate saleable Iron Ore Fines

Mining and Minerals Clear Edge

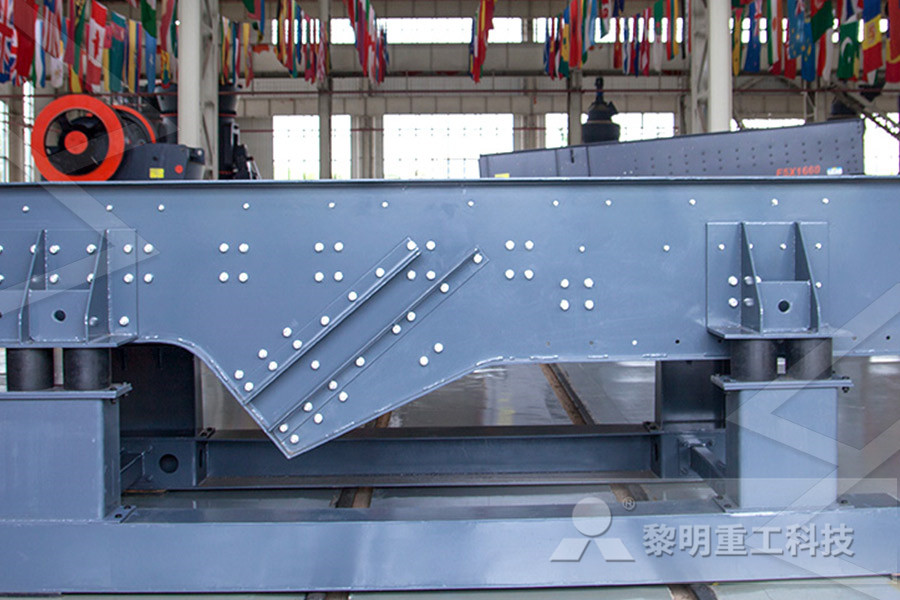

Filter presses, rotary disc filters, and horizontal vacuum belt filters are the most common filtration equipment used during the iron ore extraction process We understand the precise results needed from iron ore to make steel and our filter media has a reputation for delivering: Excellent retention efficiency and cake moisturesEQUIPMENT: Belt Feeder and Fines Hopper AIM: To redesign the hopper to achieve a reliable mass flow and uniform extraction of ore along the full length of the hopper using the existing belt feeder Australia Bulk Handling Technologies The filter media may be a continuous nylon belt alone, stretched between the shells, or disposable media can be used on top of continuous nylon belt Generally, this type of filter consists of a filter unit, a settling tank or sump, and a dragout chain The metalworking fluid mix returns to CENTRAL FILTRATION SYSTEMS FOR METALWORKING

Magnetic Filter – Permanent Magnets Ltd

Magnetic Filters are used for filtration of iron particles from products in liquid/slurry form They essentially used in chemical, food, pharma and oil industries They are also frequently used in hydraulic circuits in cooling systems The Filter Magnets are made up of either Ceramic or High Intensity Rare Earth MagnetEriez High Intensity Magnetic Filters The magnetic collection of fine particles requires a highintensity, highgradient magnetic field An electromagnetic matrixtype separator, referred to as a magnet filter, has proven to be the most effective method of separationEriez High Intensity Magnetic FiltersThis was the first iron ore pelletizing plant installed for Wuhan Iron Steel Company Equipment Specifications : Traveling Grate – 5664 mm x 69500 mm Rotary Kiln – 6858 mm diameter x 45720 mm long Annular Cooler – 21945 mm x 3657 mm Plant Commissioning : March 2006 Iron Ore Feed Material: Combination of 80% Hematite and 20% Magnetite –– Iron Ore Pelletization Iron Ore

Coolant Filtration Paper Barnes International, Inc

IM filter Water soluble and medium viscosity oils MS817: 25: Recommended for grinding cast iron and some nonferrous materials Water soluble and medium viscosity oils MS877: 25: IM filter Similar to MS817 but more strength Particularly suited for heavy emulsions MS875: 20: IM filter High flow rate and good cleaning efficiency MS Iron ore western centeral eastern Exploration Detail: 26km 8km This mine is one of the largest mineral areas in Iran, also considered to be one of the Middle East’s richest deposits it is divided in three major zones; western, central and eastern These iron ore deposits contain a total geological resource of 12 billion tons of mostly magnetite with a Fe grade from 27 to 61%Sangan Iron Ore Mines(SIOM)Filter presses, rotary disc filters, and horizontal vacuum belt filters are the most common filtration equipment used during the iron ore extraction process We understand the precise results needed from iron ore to make steel and our filter media has a reputation for delivering: Excellent retention efficiency and cake moisturesMining and Minerals Clear Edge

Magnetic Filter – Permanent Magnets Ltd

Magnetic Filters are used for filtration of iron particles from products in liquid/slurry form They essentially used in chemical, food, pharma and oil industries They are also frequently used in hydraulic circuits in cooling systems The Filter Magnets are made up of either Ceramic or High Intensity Rare Earth MagnetInnovative Technique to generate saleable Iron Ore Fines from beneficiation plant Tailings Sauvick Mazumdar RaghavendraM Subhash Naik Dy COO, IOD, Goa Ass FEED TO CERAMIC FILTER CERAMIC FILTER MAG CONCENT RATE TRIPPER CONVEYOR BELT COVERED SHED Conclusion With the synergy from the above study, further inhouse and external R D study on Innovative Technique to generate saleable Iron Ore Fines a direct coolant flow path into the coolant reservoir and can filter a wide variety of materials, both in water and oil based coolant, down to 25 microns nominal options SOLID ROTATING MAGNETIC DRUM for collecting cast iron sludge/swarf BELT TYPE hinge or scraper belt FILTER DISC DIAMETER 10", 12", 16" SINGLE OR MULTIPLE DISCSCONVEYORS FILTRATION Hennig Worldwide

Avalani Engineering Corporation Manufacturer of

When the belt carcass must be protected from the liquid being filtered, Avalani Engineering Corporation offers filter belts with fabricfree zones These belts have the entire carcass removed from exposed areas, usually around the drainage holes and often the edges of the belt The carcass of the belt is safely protected by a wall of solid rubberIM filter Water soluble and medium viscosity oils MS817: 25: Recommended for grinding cast iron and some nonferrous materials Water soluble and medium viscosity oils MS877: 25: IM filter Similar to MS817 but more strength Particularly suited for heavy emulsions MS875: 20: IM filter High flow rate and good cleaning efficiency MS Coolant Filtration Paper Barnes International, IncWe use cookies to improve your experience on our website By using our site you agree to Cookies PolicyIron Ore Processing Flowsheet Multotec

F1 Guidelines for Handling Aluminum Fines Generated

Fines and how they are generated During fabricating operations, aluminum fines may be generated by such activities as grinding, sawing, cutting, sanding or scratch brushing and at least some of them will be fine enough to be potentially explosible The term “dust” or “powder” is frequently used to describe such particles Iron ore western centeral eastern Exploration Detail: 26km 8km This mine is one of the largest mineral areas in Iran, also considered to be one of the Middle East’s richest deposits it is divided in three major zones; western, central and eastern These iron ore deposits contain a total geological resource of 12 billion tons of mostly magnetite with a Fe grade from 27 to 61%Sangan Iron Ore Mines(SIOM)Filtering colloidal clay from your water can be a difficult feat to achieve The extremely fine particles can lead to cloudy well water and cannot be removed with standard filters Typical sediment filters of 30 microns will probably not be adequateHow to Filter Out Colloidal Clay From Well Water