new process system for dal milling

2022-08-26T07:08:21+00:00

Modern Dal Milling Industries For Producing Quality

Leading Dal Milling Industries uses the unique method of Dal milling, which gives highend quality and also results mostly in providing better benefits In fact, it would be quite an awesome option for easily saving more time on producing a higher yield to the maximum level A new versatile inprocess monitoring system for milling Mathieu Ritou, Sébastien Garnier, Benoît Furet, JeanYves Hascoët To cite this version: Mathieu Ritou, Sébastien Garnier, Benoît Furet, JeanYves Hascoët A new versatile inprocess monitoring system for milling International Journal of Machine Tools and Manufacture, Elsevier,A new versatile inprocess monitoring system for milling The criteria were found to be unreliable, due to misinterpretation of sudden changes in cutting conditions Therefore, in the second section, a versatile inprocess monitoring system is suggested, to tackle the problem of reliability A new approach is proposed based on our experiments of milling forces under a range of cutting conditionsA new versatile inprocess monitoring system for

Milling process ( RICE DAL ) SlideShare

MILLING SYSTEMS A rice milling system can be a simple one or two step process, or a multi stage process In a one step milling process, husk and bran removal are done pass and milled or white rice is produced directly out of paddy In a two step process Rice and Dal are the most important agricultural products of India Rice and dal milling is an age old activity It has gone through many developments from hand process to the latest method involved rubber roller, sheller and polishing by mechanical process Dehusking of paddy and dal are most the same and the machines are also identicalPROJECT PROFILE ON RICE DAL MILL MACHINERYNew Process Milling of 185070 The Grist Mill at Keremeos, Keremeos, British Columbia, Canada, practicing their form of "new process" milling New Process Milling of 185070 by Theodore R Hazen This is probably one of the most misunderstood of all milling process, even more so, than the operation of a New Process Milling of 185070 Angelfire

A new versatile inprocess monitoring system for

Tool condition monitoring (TCM) systems can improve productivity and ensure workpiece quality, yet, there is a lack of reliable TCM solutions for smallbatch or oneoff manufacturing of industrial parts TCM methods which include the characteristics of the cut seem to be particularly suitable for these demanding applications In the first section of this paper, three processbased indicators If using 3D CAD/CAM system in conjunction with modern high speed machine tools and controls, a saving of about 40% in time of the whole process can be achieved Before discussing the specific functions required for high speed machining, we will give some examples of applications where high speed machining has been put into practiceModern Control Systems for High Speed The new biphasic system for furfural production was brought forwarded using DCM as the organic phase and the concentrated prehydrolysis liquor (CPHL) containing NaCl as the aqueous phase CPHL was obtained from the oxalic acidassisted ball milling and microwaveinduced hydrothermal treatments of corncob ( Deng et al, 2016 ), and contained A feasible process for furfural production from the pre

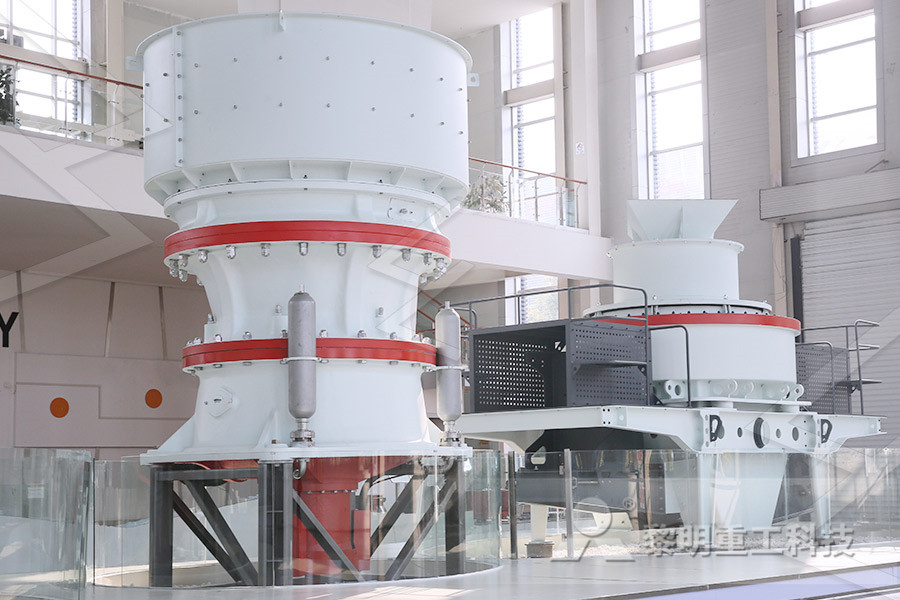

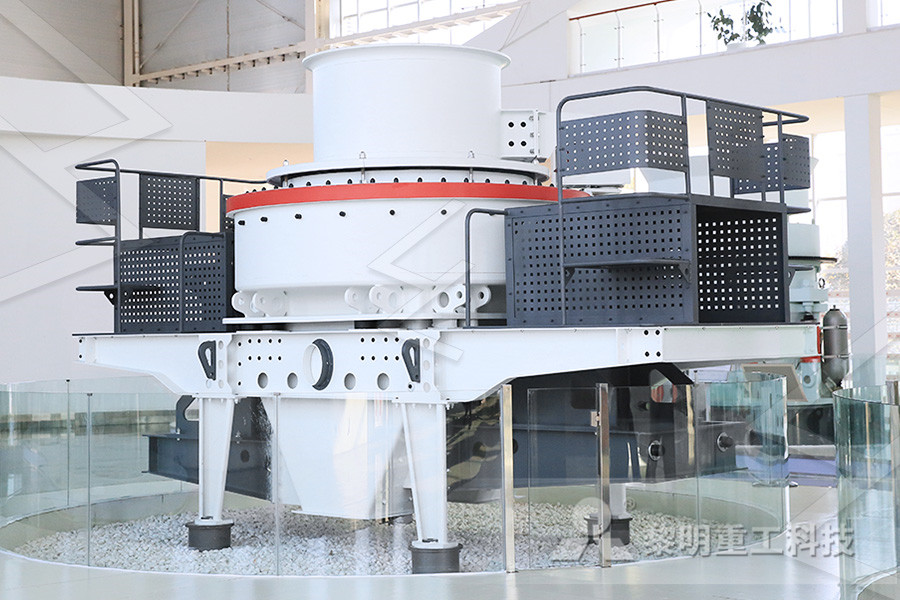

Milling Machines DAL DT Technologies

The new CORiTEC 650i and CORiTEC 650i Loader machine systems are equipped with highquality industrial milling technologies The machine impresses with its precise, vibrationfree and dynamic motion sequences in demanding and complex metal work All other materials can be milled in high quality as well with this system, in wet or dry machining Dal mills, mini dal mill, dal mill machinery, pulse mills, dal dal mill, mini dal mill, mini dal mill Flow diagram for milling of the process of details of premilling of pulses after proper cleaning is show here after in a tabulated chart »More detailedflow chart of gram dall mill MiningAbout 44% of these are flour mill, 6% are grinding equipment, and 1% are bean product processing machinery A wide variety of dal mill machine options are available to you, There are 408 dal mill machine suppliers, mainly located in Asia The top supplying country or region is China, which supply 100% of dal mill machine respectivelyChina Dal Mill Machine, China Dal Mill Machine

Types of Pulses Processing and Machinery Used for

Since sun drying is a weather dependent process, the operation of the mill stops during rainy and cloudy seasons To make conventional milling plants operational round the year, artificial or mechanical drying is essential Accordingly, various manufacturers developed some batch or continuous dryers for use in dal 6FWPD2 is our grade 1 maize milling machine mainly produce different size particle,and process 5% flour,after polishing the corn part Skip to content +86 shining@shiningallgrade 1 maize milling machineAdvanced process Milling systems A rice milling system can be a simple one or two step process, or a multi stage process One step milling husk and bran removal are done in one pass Two step process removing husk and removing bran are done separately Multistage milling can be done in the villageor local consumption or commercially for marketing rice; rice undergoes a number of different processing Milling and processing IRRI Rice Knowledge Bank

Automatic milling machines for plastic profiles

This machine reflects a new concept in modular milling system s to process largescale multiwall PVC profiles up to 355 mm in width Its modularity gives the possibility to add extra milling units, up to a max of eight, depending on type of profile, extrusion speed or milling pattern To achieve this goal, industrial wheat milling processes employ a gradual size reduction approach, through repeated milling operations (by roller mills) followed by sifting operations (by plansifters) As an example, a milling process may exploit up to seventeen different steps, arranged in a complex configuration (Campbell, 2007)Modelbased approach to the design and scaleup of Finally, the QC process must be ongoing to ensure that remedial efforts, if required, have produced satisfactory results and to immediately detect recurrences or new instances of trouble The American Association of Cereal Chemists (AACC) publishes approved methods for determining various properties of flour and bakery productsWhy Quality Control Is Important For Milling? Miller

Stone milling versus roller milling: A systematic review

1 Introduction Grain milling might be the oldest manufacturing process in the world Archaeologists have found drawings, dating back to 2600 BC, of the basic process of rubbing or grinding using two stones on the walls of Egyptian tombs (Walker Eustace, 2016)Grinding (milling) of cereal grains is the fundamental operation currently used to produce flour, which is an ingredient in many Dal mills, mini dal mill, dal mill machinery, pulse mills, dal dal mill, mini dal mill, mini dal mill Flow diagram for milling of the process of details of premilling of pulses after proper cleaning is show here after in a tabulated chart »More detailedflow chart of gram dall mill MiningProcess of Dal Milling ( Pulse Milling ) Basic processes in dal milling are cleaning, grading, conditioning, de husking, splitting, and separation, polishing and bagging Major variation is involved with de husking process only Sometimes linseed oil is also used during dry milling operation to impart shine or better appeal to the milled dalIndustrial Plant Atta Chakki Plant (Flour Mill

DS Industries Dall Milling » Pulses/Dal Mill in

DS Industries Dall Milling is Pulses/Dal Mill in Gannavaram, Andhra Pradesh, IndiaSince sun drying is a weather dependent process, the operation of the mill stops during rainy and cloudy seasons To make conventional milling plants operational round the year, artificial or mechanical drying is essential Accordingly, various manufacturers developed some batch or continuous dryers for use in dal Types of Pulses Processing and Machinery Used for Milling systems A rice milling system can be a simple one or two step process, or a multi stage process One step milling husk and bran removal are done in one pass Two step process removing husk and removing bran are done separately Multistage milling can be done in the villageor local consumption or commercially for marketing rice; rice undergoes a number of different processing Milling and processing IRRI Rice Knowledge Bank

Mill flow diagram, mill adjustment and mill balance

The use of the purification system is reduced in modern mills due to cost efficiency and efficiency in other parts of the grinding process 3 Sizing System: The duty of sizing system is to separate bran, endosperm, and germ from endosperm particles attached to the shell and came from the purification system and to refine coarse semolina which MILLMORE ENGINEERING PRIVATE LTD, with four decades of experience in rice process engineering designs, manufactures, supplies and exports Modern Rice Milling Machinery, Automatic Paddy Parboiling and Drying Plants The company has an installed capacity of machinery equivalent to complete units (mills) per monthRice Milling Machinery Manufacturer,Automatic Paddy 1 Introduction Grain milling might be the oldest manufacturing process in the world Archaeologists have found drawings, dating back to 2600 BC, of the basic process of rubbing or grinding using two stones on the walls of Egyptian tombs (Walker Eustace, 2016)Grinding (milling) of cereal grains is the fundamental operation currently used to produce flour, which is an ingredient in many Stone milling versus roller milling: A systematic review

The Importance of New “SandtoSilicon” Processes

A new method for electroplating Si using a watersol KFKCl molten salt electrolyte and highpurity gaseous SiCl4 is proposed To gain a fundamental understanding of the process, the electrodeposition of Si from Si(IV) complex ions on a Ag electrode in a molten KFKClK2SiF6 system was studied by cyclic voltammetry at 923 K 95 Dal Milling Dal milling is actually the processing of different pulses According to the availability of raw materials, you can select different various products 96 Noodles Making Generally, two types of noodles are popular One is normal and the other is instant The process is quite simple In addition, it doesn’t require much Best 113 Small Manufacturing Business Ideas for 2021