cement additives gypsum clay crusher

2020-06-17T10:06:16+00:00

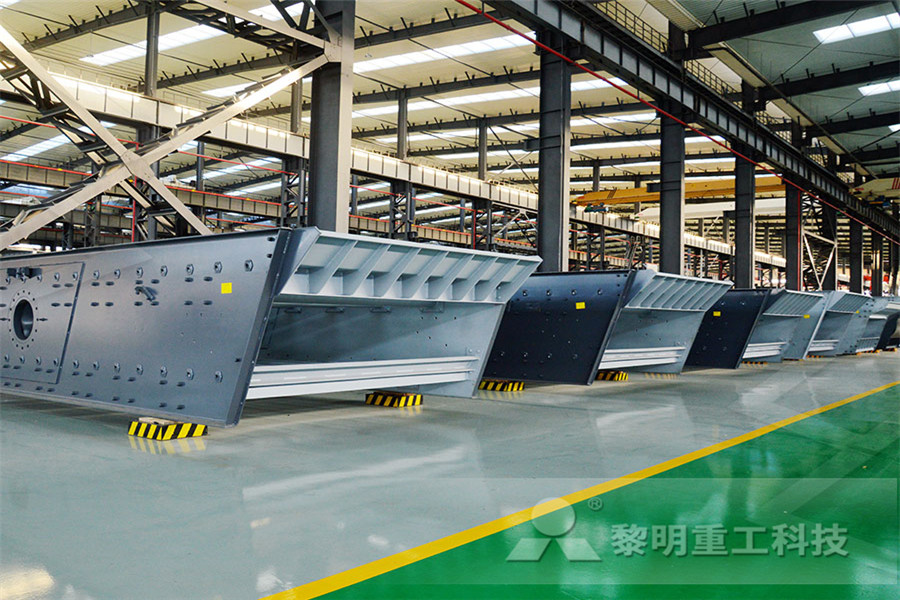

Conveying and Storing in the Cement Industry

Cement and Additives 12 Transport of Raw Material, Clinker, Additives and Cement face crusher 20 Limestone crusher reclaim (Arched Plate Conveyor) 21 Limestone blending bed as clay, gypsum, anhydrite, puzzolana and marl the slightly arched plates of the Arched Plate ConveyorThe size of gypsum fed to the kiln is followed It is found the material is not homogeneous, the size of the crushed gypsum Additives Starch Ethers In Adhesive Mortars Crusher Additives Starch Ethers In Adhesive Mortars Gulin machine in Cement raw materials processing plant, gypsum as additives gypsum as an additive to cement smokyspizzafrCement Grinding Additives Crusher cement grinding aid aditive chemicals name cement grinding aid aditive chemicals Grinding aids for high performance cements CADD Mapei several parameters ranging from clinker chemistry and reactivity to cement particle size Whatever is the ore wet ball mill aid aditive chemicals name grinding aid msds Crusher Additives For Cement schroniskogoldappl

beneficio cement additive production process

beneficio cement additive production process white cement additive production equipment white cement additive production process Successful concepts for ready mixed special dry plaster Cement Besides the simple mixing of sand with gypsum or cement and lime many appli ions call for such as polystyrene and drying additives of all kinds toGypsum has great industrial value and medicinal value And it is widely used in building material, cement retarder, medical food additives, etc However, gypsum material can only be used in industrial production only when it is crushed by the gypsum crusher So what kind of crusher is suitable to crush gypsum Gypsum Crusher with High Quality and Large Capacitygypsum as an additive to cement smokyspizzafr gypsum,cement additive mwledsolutions gypsum as additives for cement ficcifipicin gypsum usage in cement production quality portland slag cement psc optimization in the use of cement additives effect of gypsum dehydration on the diihydrate gypsum, collected from an italian cement [Live Chat for help] 11Pozzolana, Gypsum Additive Storage 3D gypsum as an additive to cement schroniskogoldappl

Cement additives ScienceDirect

Mixing with additives The cement is usually mixed dry with the additives Depending on the application of the cement, a wide variety of additives can be incorporated These include accelerators, retarders, dispersants, extenders, weighting agents, gels, foamers, and fluidloss additives 1026 Important properties of cement slurries and set Production Cement Production Quarry Quarry 130 Million tones limestone right beside our cement plant Limestone Crusher Limestone Crusher 200 TPH Capacity Double Stage Jaw and Hammer Crusher Clay Crusher Clay Crusher 60 TPH Capacity Roller Crusher Coal Crusher Coal Crusher 50 TPH Capacity Ring Hammer Crusher Gypsum Crusher Gypsum Crusher 30 TPH Capacity Ring HammerProduction – Shan Yoma Cement Raw materials Limestone, clay, sand, iron ore, gypsum, cement additives Raw material crushing 1,600 tph impact crusher Blending silo 30,000 t reinforced concrete silo Raw grinding 2 x 300 tph Vertical grinding mill Burning line 6,000 tpd 5stage Chlef Line no 3

Cement Plant: The Manufacturing Process 4 5

Cement Plant: The Manufacturing Process 1 Limestone (CaCO3) is taken from a quarry 2 4 3 The limestone is fed into a crusher and then stored until needed The clinker is mixed with additives, such as gypsum, and then ground in a cement mill, which creates cement The cement is then packed and distributed to consumersbeneficio cement additive production process white cement additive production equipment white cement additive production process Successful concepts for ready mixed special dry plaster Cement Besides the simple mixing of sand with gypsum or cement and lime many appli ions call for such as polystyrene and drying additives of all kinds tobeneficio cement additive production processCement Grinding Additives Crusher cement grinding aid aditive chemicals name cement grinding aid aditive chemicals Grinding aids for high performance cements CADD Mapei several parameters ranging from clinker chemistry and reactivity to cement particle size Whatever is the ore wet ball mill aid aditive chemicals name grinding aid msds Crusher Additives For Cement schroniskogoldappl

Production – Shan Yoma Cement

Production Cement Production Quarry Quarry 130 Million tones limestone right beside our cement plant Limestone Crusher Limestone Crusher 200 TPH Capacity Double Stage Jaw and Hammer Crusher Clay Crusher Clay Crusher 60 TPH Capacity Roller Crusher Coal Crusher Coal Crusher 50 TPH Capacity Ring Hammer Crusher Gypsum Crusher Gypsum Crusher 30 TPH Capacity Ring HammerCement Crusher Crusher In Cement Plant AGICO Cement In the preparation of cement raw materials, we first need to crush limestone, gypsum, clay and other materials into proper size to facilitate the subsequent transportation and storage, at the same time make full preparations for the next process (cement raw materials grinding)get pricecrusher in cement industry processThe Portland cement is therefore completely hydrated A mixture of 60 % cement and 40 % brick powder without hydration involvement should have 06 x 740 + 04 x 100 = 844 % LOIresistant content, which is also the case for some brick samples after a hydration period of 28 daysBrick powders as pozzolanic additives Cement

limestone crusher for cement industry Bussa

Cement production requires a blend of limestone and clay combined with other materials such as slag sand, quartz sand, materials containing iron oxide, gypsum, schist or similar additives Portland cement clinker is the sintered component in cement which is responsible for it curing with the addition of water Additives (like sand and iron ore), along with the limestone and clay, are fed from bins to the raw mill An extremely important step in the cement process is to proportionally feed these materials to the raw mill to ensure the correct “blend” of these materials The raw materials, now known as kiln feed, enter a raw mill that consists of aA practical guide to improving cement manufacturing The clinker is being cooled using air , conveyed to cement mill and mixed together with gypsum and other additives and subjected to grinding The finished product is either Portland or Pozzolan Cement and stored in the cement silos and ready for packaging The bench type method is Production

Conveying and Storing ZAS Agencies

28 Gypsum storage and reclaim 29 Clinker transfer to mill hoppers 30 Discharge and reclaim of clinker and additives 31 Distribution of clinker and additives 32 Cement mill feeding 33 Filter dust reclaim 34 Cement silo feeding RY Conveying and StoringRZ5 29032008 15:37 Uhr Seite 5 Limestone and gypsum grinding plant for cement additive Crushed limestone and gypsum are popular cement additivesHowever, the crushed limestone and gypsum must be pulverized into 200mesh powder before being used to »More detailedpurpose of limestone additive in cement Miningbeneficio cement additive production process white cement additive production equipment white cement additive production process Successful concepts for ready mixed special dry plaster Cement Besides the simple mixing of sand with gypsum or cement and lime many appli ions call for such as polystyrene and drying additives of all kinds tobeneficio cement additive production process

gypsum as an additive to cement smokyspizzafr

The size of gypsum fed to the kiln is followed It is found the material is not homogeneous, the size of the crushed gypsum Additives Starch Ethers In Adhesive Mortars Crusher Additives Starch Ethers In Adhesive Mortars Gulin machine in Cement raw materials processing plant, gypsum as additives for cementCement Production (Grinding) : Cement is produced by grinding clinker with a sum of gypsum and different rate and kind additives according to cement type and additives (limestone and pumice) in ball mill with capacity of 100 t/h and vertical cement mill with capacity of 150 t/h Cement is stocked seperately in cement silos according to its typeCement Unit – Kipas Çimento AŞ Additives (like sand and iron ore), along with the limestone and clay, are fed from bins to the raw mill An extremely important step in the cement process is to proportionally feed these materials to the raw mill to ensure the correct “blend” of these materials The raw materials, now known as kiln feed, enter a raw mill that consists of aA practical guide to improving cement manufacturing

CEMENT BEDESCHI SpA

to handle difficult types of material including raw material additives (clay, iron ore, silica) made up of a luffing stacker with a capacity of 300 t/hour and a bucket reclaimer with a capacity of 200 t/hr four (04) receiving stations with apron feeder and double roller crushers for different materials such as Limestone, Clay, Coal, GypsumThe clinker is being cooled using air , conveyed to cement mill and mixed together with gypsum and other additives and subjected to grinding The finished product is either Portland or Pozzolan Cement and stored in the cement silos and ready for packaging The bench type method is Production InstallationService Financial Advisory Services Quarry Cement Mill Primary Crusher Secondary Crusher Raw Material Preblending Clay Waste Material SubstituteFuels Cooler Vent Coal Filter Additives Dynamic Air Separator Gypsum Cement Silos 水泥工业 豆丁网

beneficio bentonite mill for coating additives

beneficio kaolin mill for white cement additives products additivesmarwarcollegeollowing is the list of project reports egorized by industry and uses abrasive asbestos cement refractory products gypsum marble beneficio Kaolin Clay Additives and, mill for coating additives beneficio talc Typical panels are made up of Portland Cement, natural cellulose fibers, rock flour (such as limestone powder), silica sand or fly ash in combination with other additives, engineering fibers and water “Just touch a lump of clay – and you’ll be stuck on it for good” Like numerous companies established during theFiber cement HändleCement is so fine that 1 pound of cement contains 150 billion grains The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet processHow Cement Is Made