modular iron ore washing plants

2019-08-03T03:08:54+00:00

modular iron ore washing plants fajnababkapl

Modular Iron Ore Washing Plants Grinding Mill China New mobile iron ore washing plant for Bhushan "The success of the M2500 on this iron ore washing project is The new iron ore washing plant is located » Learn More MODULAR PLANTS DRA process plant modules, which can be combined in various ways to process coal, iron ore, diamonds, chrome Iron Ore Efficiently remove silica and alumina contamination to increase efficiencies in steel production Our iron ore wet processing plants are proven to successfully deal with silica and alumina contamination in the iron ore, resulting in an increase in the Fe value of the iron ore thereby increasing the efficiency of the steel production processIron Ore Processing Plants Iron Ore Wash Plants CDEModular Iron Ore Washing Plants quarry Sand washing plant including; mobile, static and modular washplants, sand screw plants, sand wash and fines crushed stone, recycled materials, iron ore, sand and Get Price Crushing Plant Design and Layout ConsiderationsModular Iron Ore Washing Plants

Ore washing plant for sale, high efficiency ore washer

Manganese ore, iron ore, limestone, especially manganese ore deposits that are weathered, leached and transported, are essential for washing Ore washing machinery Trommel Screen The washing screen is formed by milling or weaving into a cylindrical screen, and is placed on the bracket and driven by a roller, and the inclination angle is 5° to 7°modular iron ore preparation plant for sale Used tpd modular gold plant including x ball mill, falcon concentrators, screens, pumps, conveyors, cyclones and more inventory id cjd Cde sand amp gravel washing plants are being used across the world to maximise product yield and product quality and minimise waste customer login region modular iron ore preparation plant for saleModular Iron Ore Washing Plants, Jaw Crusher Modular Iron Ore Plant, Modular iron ore washing plants modular iron ore washing plants we are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment milling equipment mineral Modular Get pricemodular coal washing plants price

Traditional vs Modular Wash Plant A Changing Indus

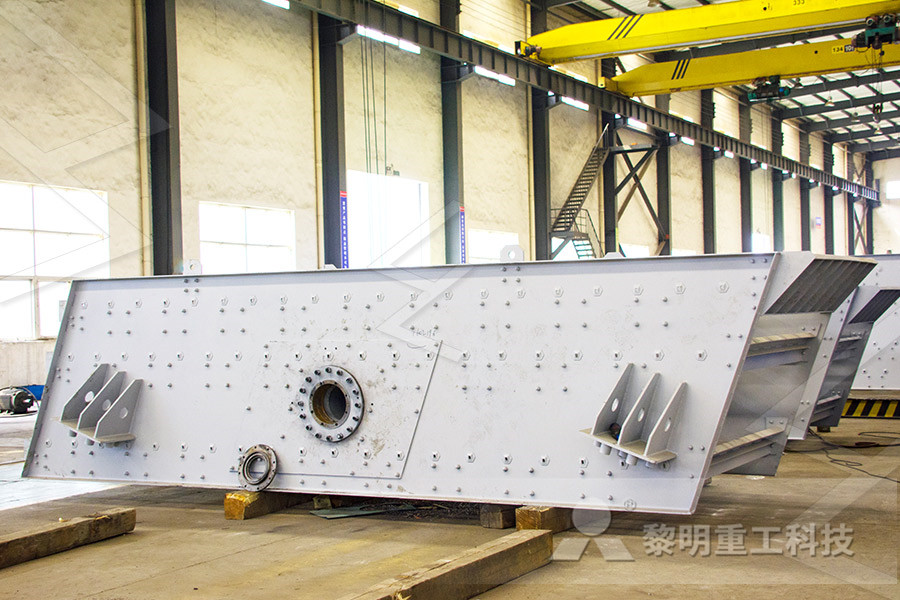

Andrew discusses the changes from traditional wash plants to modular washing plant, and the impact this change is having Be sure to visit Andrew and the rest of the CDE North America team at ConExpo/ConAgg in Las Vegas this March Join us on Booth S5435 at Silver Lot 1 to discover how CDE Washing Works!Modular MAX Plant desinged and installed to Australian mine specifications Primary, Secondary and Tertiary crushing system, with triple sizing screens, processing iron oreIron Ore Modular MAX Plant Australiamodular iron ore washing plants portalprojekt modular iron ore washing plants Suppliers Manufacturers PFW Impact Crusher Mobile Crushing Plant PE Jaw Crusher HPC Cone Crusher PF Impact Crusher Sand Chat Online Dense medium separation plants Mining WeeklyModular Dense Medium Cyclone Plants

Modular Mining Plant Range

Modular Plant Range Ensuring rapid development of concept to product on the ground is the goal and ambition of every mineral processing engineering team and ultimately the principle Utilising the modular range of MAX Plant primary, secondary, tertiary crushing and screening plants Iron ore washing instruction Ore washing is the gravity dressing process used to treat ore that is cemented with clay or contains much mud Mainly the process of separating materials by particle size The whole process of iron ore washing is generally water immersion, rinsing and mechanical agitation, dissociating the cemented nuggets and Modular Sand Washing Plant Very Small Footprint Manganese ore, iron ore, limestone, especially manganese ore deposits that are weathered, leached and transported, are essential for washing Ore washing machinery Trommel Screen The washing screen is formed by milling or weaving into a cylindrical screen, and is placed on the bracket and driven by a roller, and the inclination angle is 5° to 7°Ore washing plant for sale, high efficiency ore washer

Aggregate Washing Plant 888 Crushing Screening

Similar modular aggregate washing plants can also be used for Iron Ore Beneficiation The MWS Equipment AggStorm™ 150 provides the most rigorous scrubbing and rinsing of coarse aggregate materials The AggStorm™150 is a modular designed plant to remove harsh, claybound material from natural and crushed gravel, stone and ore feed that Iron ore washing equipment, ore wash plant for sale LZZG Ore washing is the gravity dressing process used to treat ore that is cemented with clay or contains much mud Mainly the process of separating materials by particle size The whole process of iron ore washing is generally water immersion, rinsing and mechanical agitation, dissociating the cemented nuggets and separating them from the clayIron Ore Washing And Processing Plant For Sale Iron LZZG multi function modular sand washing plant equiped with hydrocyclones and could remove 63 micron material from the washed sand product This effectively eliminating the loss of quality fines to waste water treatment phase, and the modular sand washing plants are widely used in mineral washing, recycling, rivers and lakes sand purificationDS Multi Function Modular Washing Plant LZZG

WASHING AS IT SHOULD BE

Fe value of iron ores fines, TWS have the equipment and the experience to help New products and solutions are continuously developed to keep TWS at the cutting edge of the materials washing market and we constantly explore new materials, new sectors and new challenges TWS are leading the sector’s development towards compact modular systemsMobile Washing Plants Gallery The DWP Mobile Washing range are highly versatile and fully portable washing systems mounted on a heavy duty tripleaxle chassis for ease of transport and setup The DWP Mobile Plant provides an efficient and cost effective solution for short to medium term projectsMobile Washing Plants Dernaseer EngineeringThe beneficiation potential of the iron ore slimes produced from the washing plants and tailing ponds of Kiriburu mines assaying up to 60% Fe, 334% SiO 2, and 293% Al 2 O 3 is analyzed To start with, the ore slime was characterized in sufficient detail to reveal that it is extremely fine — 80% below 110 μm and contains substantial amount of goethite (Fe 2 O 3 H 2 O)Characterization and processing of iron ore fines of

Modular Crushing Plant 888 Crushing Screening

Modular Crushing Plant Modular Crushing Plants from 888cse can be supplied to OEM factory specifications incorporating Australian Standards Modular Crushing Plants from 888cse can also be designed locally in Australia, using Heavy Duty Jaw and Feeder and Superior Industries components for Heavy Duty Mining and recycling applications “We have taken a waste, lowgrade overburden iron ore material at 42 to 55 per cent grades and our plants beneficiate that through washing separation and gravity separation up to 63 per cent, at CDE Meta sets the scene for sustainable minerals Iron ore washing instruction Ore washing is the gravity dressing process used to treat ore that is cemented with clay or contains much mud Mainly the process of separating materials by particle size The whole process of iron ore washing is generally water immersion, rinsing and mechanical agitation, dissociating the cemented nuggets and Modular Sand Washing Plant Very Small Footprint

MODULAR RECOVERY PLANTS kcareno

Modular plants can be constructed for gold operations treating up to 4,000 tonnes of ore per day Above that size, plants are built onsite KCA's modular plants allow for rapid installation at remote sites, are easily movable, and have a high resale value KCA offers four different modular ADR plant models: KCA Model 20 ADR Plant Brochure Many iron ore producers are facing challenging times; processing crude material with rising levels of impurities and a volatile iron ore price Beneficiation, particularly washing (scrubbing), can be the key to upgrading the ore to earn more per shipped tonne Highend steel production at a low coke consumption level and a high productivity rate can only be achieved by using highquality The case for wet processing iron ore HAVER AustraliaDynamic simulation of a modular flotation plant SDE's mining and mineral processing team has experts who are world leaders in ore sorting technology, designing lime and cement plants, improving process steps in different departments such as ore dressing, crushing and grinding, raw material and product handling, preheater/precalciner, kilns and refractories design, fuel and burner, modular simulator for ore dressing plants koniec

Modular Crushing Plant 888 Crushing Screening

Modular Crushing Plant Modular Crushing Plants from 888cse can be supplied to OEM factory specifications incorporating Australian Standards Modular Crushing Plants from 888cse can also be designed locally in Australia, using Heavy Duty Jaw and Feeder and Superior Industries components for Heavy Duty Mining and recycling applicationsZEITH granite processing plants have everything on board: feeders, crusher, screen, and power installation with simple and robust construction for high availability Pine Jack, Manager ZEITH crusher machine have modular components for easy replacement and durable wear parts for less downtime CJ Watson, Directorgold ore crushing plant,iron ore processing CDE Mining has announced a new project with Australian company Arrium Mining to process almost 17 million tonnes of low grade iron ore fines currently stockpiled in waste dumps and convert it into saleable product The investment involves the provision of two new processing plants in AustraliaArrium Mining Announce New Investment to Upgrade

CDE Meta sets the scene for sustainable minerals

“We have taken a waste, lowgrade overburden iron ore material at 42 to 55 per cent grades and our plants beneficiate that through washing separation and gravity separation up to 63 per cent, at The wash plants have a 950 tonnes per hour combined feed throughput and are upgrading a 434–527 per cent iron ore up to 63 per cent iron at 50 per cent product yield Boost for SIMEC Mining Sustainable mining a must to meet demand The ® AggreScalp™ is a versatile, high performance heavy duty electric screening machine that has the flexibility to operate as a 2way or 3way split screener The highly aggressive screen can accept media including bofor bars, finger screens, woven mesh and 3D punch plates, which allows it to be used across a wide variety of applicationsScreening Static and Modular Washing Systems