Mills And Kilns In Cement Plant

2020-08-23T17:08:34+00:00

Cement Directory: Drives for Mills and Kilns

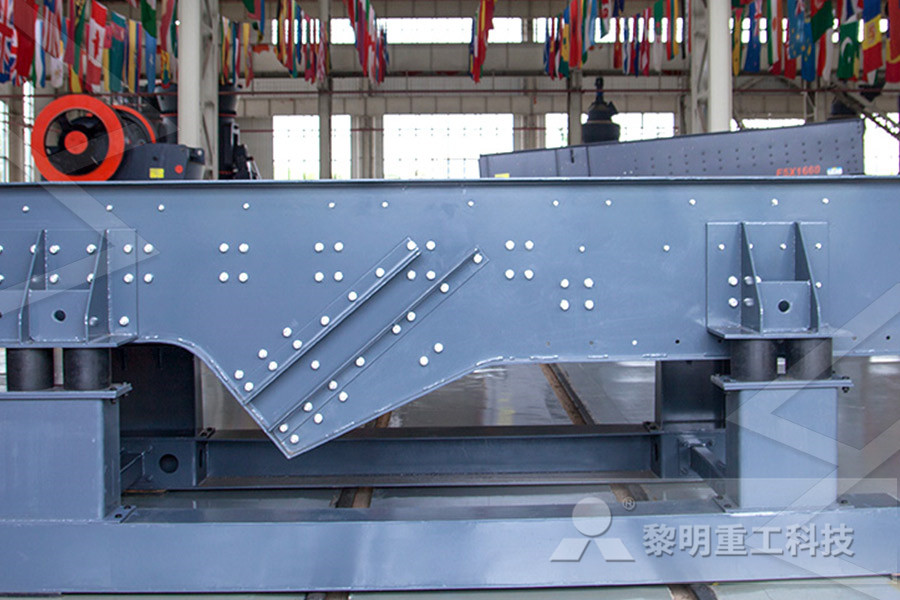

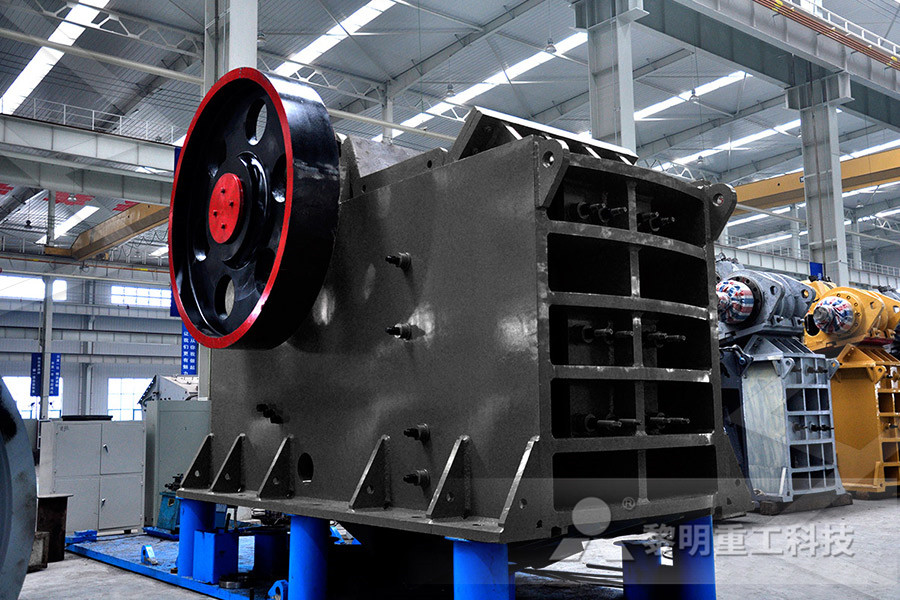

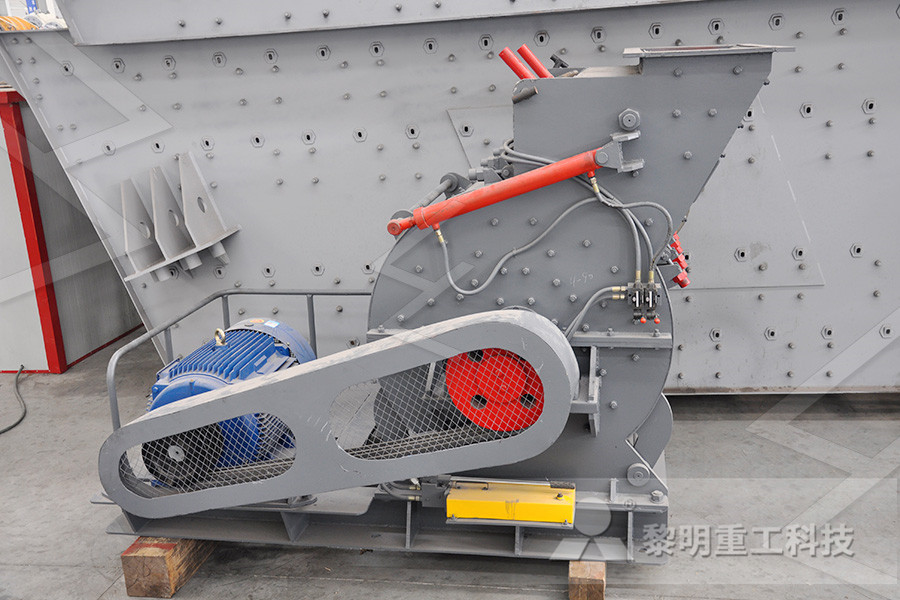

Gold Sponsor Rotary Kiln Services Australasia 32 Vickers Street Edmonton 4869 Australia Our general products and services include: Supply and installation of new rotary vessels such as Kilns, Calciners, Dryers, Coolers, Roasters Supply and installation of new Grinding Mills includi Cement Plants and Kilns in Britain and Ireland About this site About cement About clinker List of plants Map of plants Raw materials About Kilns Other technical advances Trends in innovation Sources Historical Texts Reference Essays Contact Site MapCement Plants and Kilns in Britain and Irelandball mill of cement plant Industrial ball mills made available by us are heavy sheet fabricated using qualityapproved mild steel stainless steel These ball mills are used to grind materials into extremely fine powder Our ball mills are perfect for cement plants Three types of ball Mills we re manufacturing: – 1 Raw materials mill 2 Cement (Clinker) mill 3maintenance of mills of cement plants

Side Drive for mills and kilns Wikov

OAO SpasskCement Spassk Cement located in SpasskDalny close to Vladivostock in Russia's Far Eastern Federal District is a plant of the private OOO VostokCement group The plant has precalciner rotary kiln and 5 tube mills The cement capacity is 34 Mta and 95% of its output is sent to the domestic market Photo gallery The kilns are the wellknown Schneider kilns The whole plant has been erected under expert supervision, and by local workmen, who now, under the experienced cement works manager, Mr Greaves, manufacture the cement The company has built Cement Kilns: CouslandWet process kilns The original rotary cement kilns were called 'wet process' kilns In their basic form they were relatively simple compared with modern developments The raw meal was supplied at ambient temperature in the form of a slurry A wet process kiln The cement kiln

MPCbased solution for advanced kiln control at Bursa

The Bursa Cimento plant is located near the city of Bursa in the Marmara region of Turkey Bursa is one of the most populated cities in Turkey and an important industrial area Bursa Cimento operates two clinker lines and four cement grinding mills plant’s overall performance Hence its advantage as a graphical engineering and programming environment, used to control and optimize • Kilns • Mills • Alternative fuels with a combination of proven and advanced control techniques OptimizeIT Expert Optimizer adds value to the operational performance by bringing the process closer to Industrial : Optimization for the Cement IndustryCement Plants with Rotary Kilns 200 TPD1000 TPD Individual equipment and components such as jaw/hammer crushers, ball mills, ball mill drives, kilns, conveyors, elevators, feeders, blower's etc Spare parts such as gears, gear reducers, tyres, rollers, mill headers etcCement Plants Cement Plant Equipment, Rotary Kiln

Cement Plants located in United States CemNet

Cement plant locations and information on United States can be found below For full access to the database, purchase The Global Cement Report™, 13th EditionWet process kilns The original rotary cement kilns were called 'wet process' kilns In their basic form they were relatively simple compared with modern developments The raw meal was supplied at ambient temperature in the form of a slurry A wet process kiln may be up to 200m long and 6m in diameterThe cement kiln Understanding CementCement C3S, C2S, C3A, C4AF Burnability index (for clinker) Burnability factor (for clinker) Burning temperature (minimum) Go To Online Calculators 28days mortar strength Mpa Gypsum Set Point (GSP) Go To Online Calculators Grinding Calculationscement plant calculations kiln, mills, quality, combustion

Cement Kilns: Burham

The plant was initially primarily concerned with brick making, using the Gault Clay quarry immediately adjacent to the plant, but also made hydraulic lime and Portland cement The initial installation was described on its sale in 1859 as "consisting of engine and house, washing mills, some four kilns, with accompanying drying stoves and nine ball mill of cement plant Industrial ball mills made available by us are heavy sheet fabricated using qualityapproved mild steel stainless steel These ball mills are used to grind materials into extremely fine powder Our ball mills are perfect for cement plants Three types of ball Mills we re manufacturing: – 1 Raw materials mill 2 Cement (Clinker) mill 3maintenance of mills of cement plantsOAO SpasskCement Spassk Cement located in SpasskDalny close to Vladivostock in Russia's Far Eastern Federal District is a plant of the private OOO VostokCement group The plant has precalciner rotary kiln and 5 tube mills The cement capacity is 34 Mta and 95% of its output is sent to the domestic market Photo gallerySide Drive for mills and kilns Wikov

Cimenterie Nationale Cement Mills

The Cement Mills Department is one of the major departments of a Cement Plant where the produced clinker, mixed with additives such Gypsum, Pure Limestone and Granulated Blast Furnace Slag, is ground to a low degree of fineness to produce the greycolored powder known as Cement Machinery and equipment in the cement industry include conveyors, silos for storing clinker and cement, kilns, vertical roller mills, ball mills, weighing and packaging equipment of various types Engineering design of a cement plant requires an individual approach to each project using the equipment that will be beneficial in a particular Cement plant design under EPC contract ESFCExporter of Cement Plant Equipment Cement Kilns, Fly Ash Dryers offered by Varsha Techno Ind Equip Pvt Ltd, Hyderabad, TelanganaCement Plant Equipment Cement Kilns Exporter from

MPCbased solution for advanced kiln control at Bursa

The Bursa Cimento plant is located near the city of Bursa in the Marmara region of Turkey Bursa is one of the most populated cities in Turkey and an important industrial area Bursa Cimento operates two clinker lines and four cement grinding millsPlant Performance Reviews and Analysis with a view to enhancing production output, efficiency and cost reduction Coordination of Maintenance programmes with Heads of Maintenance Departments as well as Heads of Sections in Production to achieve the targeted availability of Raw Mills, Kilns and Cement and Coal Grinding EquipmentManager Production, Raw Mill Ibeses Plant (Cement) At ball mill of cement plant Industrial ball mills made available by us are heavy sheet fabricated using qualityapproved mild steel stainless steel These ball mills are used to grind materials into extremely fine powder Our ball mills are perfect for cement plants Three types of ball Mills we re manufacturing: – 1 Raw materials mill 2 Cement (Clinker) mill 3maintenance of mills of cement plants

Cimenterie Nationale Cement Mills

The Cement Mills Department is one of the major departments of a Cement Plant where the produced clinker, mixed with additives such Gypsum, Pure Limestone and Granulated Blast Furnace Slag, is ground to a low degree of fineness to produce the greycolored powder known as Cement And we supply 43*64m rotary kilns and 38*13m ball mills for Pakistan Lucky Cement Factory, two comprehensive sets of cement production lines for Myanmar Dragon Cement Factory, 5*74m rotary kilns and 38m wind swept coal mills of four cement production lines for National Industry Cement Co, LtdChina Cement Production Line manufacturer, Cement plant’s overall performance Hence its advantage as a graphical engineering and programming environment, used to control and optimize • Kilns • Mills • Alternative fuels with a combination of proven and advanced control techniques OptimizeIT Expert Optimizer adds value to the operational performance by bringing the process closer to Industrial : Optimization for the Cement Industry

Raw And Cement Mills Producers skuderch

as of 1900, the coplay cement plant, using continuous kilns, had a maximum production of 500 barrels of portland cement per day before the raw materials Raw And Cement Mills Producers,what does a cement plant of the future look like? (part 2) why cement producers need to embrace industry 40 raw mill in cement production Mills Producers In Cement Industry,you may be interested tube ball mill Cement plant gearboxes tend to be overloaded and consequently they often overheat, resulting in expensive premature wear and failure of the gears Other common mechanical issues include emulsification of the gear oil due to water contamination and extreme foaming Kilns and ball mills are two of the most critical pieces of equipment for Cement Concrete Lubrication EngineersIn 1926, investors contracted to build a new wet process cement manufacturing plant on about 400 acres in the limestone rich Lehigh Valley Keystone Cement was started with four small rotary kilns, four raw mills, and four finishing mills in 1928 In the years that followed, additional land was purchased, increasing the total acreage to Giant Cement Company About Us

About Us – Kuwait Cement Company

The Company has constructed two kilns for the production of clinker (the raw material used in cement manufacturing) The first kiln began operation in year 2001, while the second in year 2013, together with the associated mills, heat exchangers, clinker storage silos, and other advanced technological equipments and machinery Devnya Cement 1954: Construction of a cement plant in Devnya begins 1958: On December 4th, the largest cement plant in Bulgaria 1963 – 1964: The first expansion of the plant is underwayTwo new kilns are installed along with four new silos and aggregates transportation equipment 1975 – 1978: The second expansion of the plant is underway with an additional two kilns constructedOur History Devnya Cement Cement’s Essexville, MI grinding plant The US cement industry lost 3102 mmt of finish grinding capacity since the previous survey Since the 2010 survey, Essroc Cement Co’s Essexville grinding plant ceased operations and Essroc’s grindingonly facility in Nazareth, PA was combined with their clinkerproducing plant – bringing the US Portland Cement Industry: Plant Information Summary