wrapper roll hot strip mills

2022-06-23T23:06:03+00:00

Wrapper Roll Control System of Hot Strip Mill

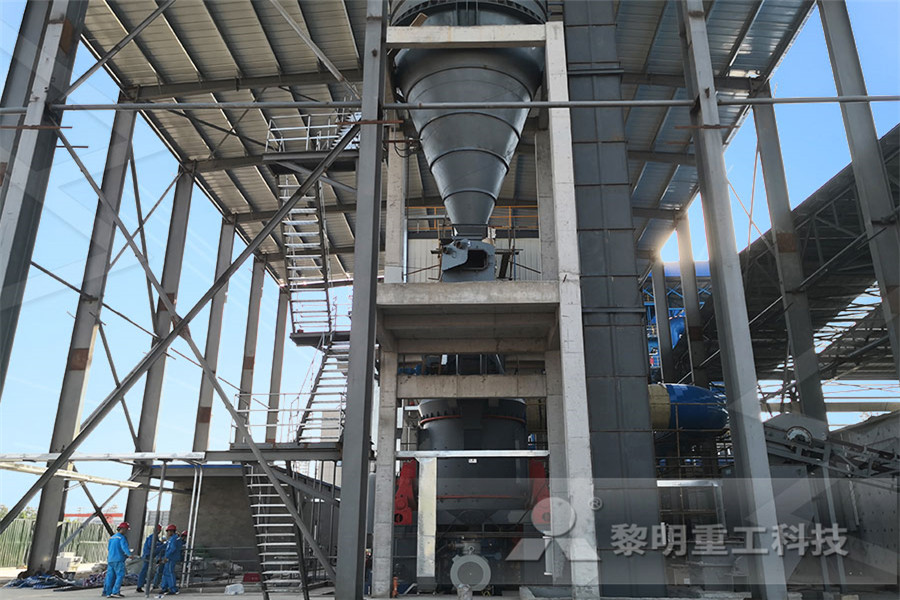

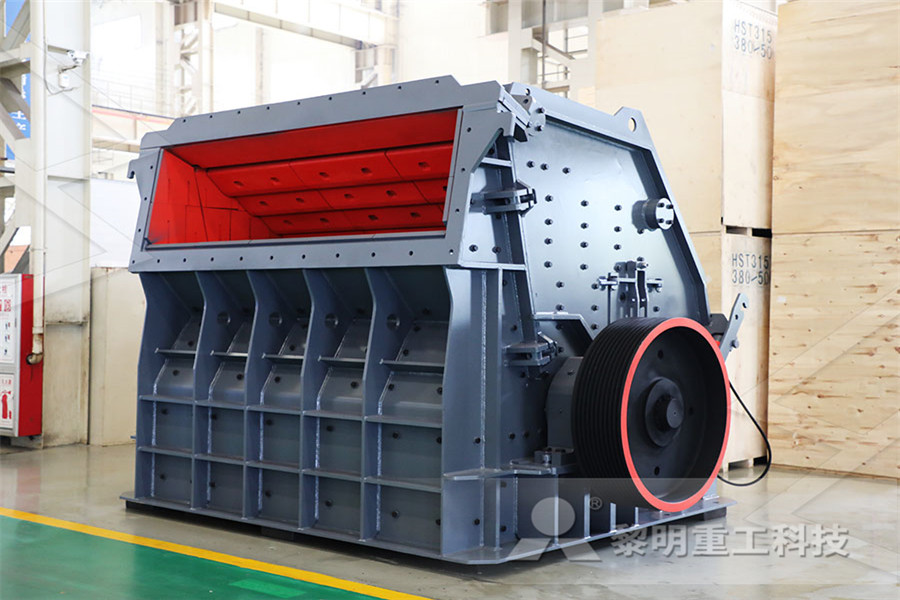

Wrapper roll is one of the most important components in rolling coiler And it has great relation to the quality of the final products Based on the programming and optimization experience, a hot strip coiler with new coiling process, which operates with position control and pressure control is introduced terface through the console The second stage, when the strip tail through the last finishing mill and signal from 1 to 0, the speed of mandrel equals the speed of strip which switch from tension control to speed control, the speed of the hot run out table, pinch roll and wrapper roll is less than the speed of strip, the value of lag rate isDesigning of Hot Strip Rolling Mill Control SystemThe second stage, when the strip tail through the last finishing mill and signal from 1 to 0, the speed of mandrel equals the speed of strip which switch from tension control to speed control, the speed of the hot run out table, pinch roll and wrapper roll is less than the speed of strip, the value of lag rate is given in manmachine interface Designing of Hot Strip Rolling Mill Control System

Highest performing Hot Strip Mills Primetals

HOT STRIP MILL — HIGHEST PERFORMANCE FOR NEW AND EXISTING STEEL MILLS The demand for hot rolled strip is growing in multiple ways To remain competitive, new and existing mills must meet this challenge in the best possible way The production of hot strip is a key element of steel production strip down coiler installed at this plant has following characteristics: – 3 wrapperroll type Hoesch Hohenlimburg/GERMANY Max/Min strip width, [mm] 715/150 Max/Min strip thickness, [mm] 17/1 Max hot yield stress, [N/mm²] 1000 Min coiling temperature, [°C] 300 Max coil weight, [to] 15 Max coil diameter, [mm] 2,000Innovations for Coiling of Modern Hot Rolled Flat Materials The mechanical rolling conditions in hot strip mills are precisely defined by various variables, which are taken directly froth the rolling schedule (separation force, torque speed strip thickness) or calculated from figures of the rolling schedule and dimensions of the mill (strip reduction, roll Rolling conditions in hot strip mills and their influence

The Hot Rolling Process California Steel

The Hot Rolling Process The primary function of the Hot Strip Mill is to reheat semifinished steel slabs of steel nearly to their melting point, then roll them thinner and longer through 12 successive rolling mill stands driven by motors totaling 77,000 hp, and finally coiling up the lengthened steel sheet for transport to the next process INTRODUCTION In hotsteelstrip rolling mills it is essential to have adequate facilities for roll cooling if a satisfactory performance is to be obtained as regards to roll life, strip surface, strip crosssection profile and an overall high standard of production qualityLubrication of hotstripmill rolls ScienceDirect CVC technique has slower dynamics but a wider range than work roll bending Since CVC and work roll bending complement each other, both the techniques are normally used in the modern hot strip mills During recent years, there is an increasing demand on the profile, thickness, flatness and the surface of the hot stripRolling of steel in Hot Strip Mill – IspatGuru

GENERAL ASPECTS OF ROLL COOLING FOR HOT COLD

advantages of HSS rolls in hot strip mills, and selective roll cooling systems as a method to control the flatness of the strip in cold rolling mills Cooling and lubricating is furthermore essential for the plateout for cold rolled strip Typical methods how to apply coolant onto the rolls are described and discussed Various nozzle types and 4Hi/6Hi Tandem Hot Strip Mills: Magadh can offer 4Hi/6Hi Tandem Hot Strip Mills (5 Stand or 6 Stand) for strip width upto 1670 mm, 900 MPM speed and finish strip thickness of 125 mm to 18 mm The main mill features are :MagadhOur service range includes complete roll systems ready for installation in continuous casting plants, run out table rolls for hot strip mills including cross bars and all accessories as well as wrapper guide plates ready for installation with the appropriate GW W1 PREMCO ES wrapper rollRoll Systems Gustav Wiegard MASCHINENFABRIK

Hot Cold Rolling Mill Equipment Manufacturers

The modern hot strip mill is furnished with a tremendous amount of equipment from the reheat furnaces all the way down to the coiling equipmentFortunately for both our ferrous and nonferrous customers alike Butech Bliss can provide equipment and technical services for nearly every element of the hot strip terface through the console The second stage, when the strip tail through the last finishing mill and signal from 1 to 0, the speed of mandrel equals the speed of strip which switch from tension control to speed control, the speed of the hot run out table, pinch roll and wrapper roll is less than the speed of strip, the value of lag rate isDesigning of Hot Strip Rolling Mill Control System CVC technique has slower dynamics but a wider range than work roll bending Since CVC and work roll bending complement each other, both the techniques are normally used in the modern hot strip mills During recent years, there is an increasing demand on the profile, thickness, flatness and the surface of the hot stripRolling of steel in Hot Strip Mill – IspatGuru

Main Features of a modern Hot Strip Mill – IspatGuru

Since CVC and work roll bending complement each other, both the techniques are normally used in the modern hot strip mills Fig 2 work roll bending and continuous varying crown Roll eccentricity compensation – Roll eccentricity is a periodic disturbance caused by a structure of back up rolls in rolling mills, and it affects product thickness The Hot Rolling Process The primary function of the Hot Strip Mill is to reheat semifinished steel slabs of steel nearly to their melting point, then roll them thinner and longer through 12 successive rolling mill stands driven by motors totaling 77,000 hp, and finally coiling up the lengthened steel sheet for transport to the next processThe Hot Rolling Process California SteelManjira has over 20 years experience in producing Hot Strip Mill Terminal Equipments as per Customers Designs and Drawings and manufactured and supplied the following terminal equipments for Hot Strip Mills: JSW Steels Ltd, Bellary: Down Coiler Pinch Roll and Wrapper Roll Assemblies Coil Box Transfer Arms and Coil Box Guides with Roller TablesStrip Processing Lines Cold Rolling Mills

Coiling Simulation and Control Method for Hot Strip

Two types of pinch roll have equal method generating tension is induced by pressing strip between upper roll and bottom roll Fig 2 shows the hinge type pinch roll and governing Eq (I) is expressed by friction coefficient between strip and roll Fig 3 shows the housing type pinch roll, it is similar in shape to the hot mill stand The growth of the scale prior to rolling was controlled and the thickness of the layer of scale at the entry remained in the range of 20–100 μm, somewhat higher than in the finishing train of a hot strip mill Roll separating forces, roll torques, the speed, the The Coefficient of Friction During Hot Rolling of Low Wrapper Rolls are manufactured according to the application conditions with electroslag welding or with thermal coating Run Out Table Rolls are manufactured in all different executions, starting from T1TC which is a thermal coated roll, to internal cooled run out table roll with strip cladding We also supply stainless run out table rollsPacific InternationalFORGED ROLLS FOR HOT STRIP

Hot Strip Mills – Yume Technologies Private Limited

Hot Strip Mills The solution for Hot Strip Mill includes complete automation and drives systems for: Roll Gap control with Automatic Roll gap Calibration and Mill Stretch Calibration Technology Control for Down Coiler including Mandrel expansion and Wrapper roll technology control; Automatic Gauge Control including Mill Stretch Our service range includes complete roll systems ready for installation in continuous casting plants, run out table rolls for hot strip mills including cross bars and all accessories as well as wrapper guide plates ready for installation with the appropriate GW W1 PREMCO ES wrapper rollRoll Systems Gustav Wiegard MASCHINENFABRIK The modern hot strip mill is furnished with a tremendous amount of equipment from the reheat furnaces all the way down to the coiling equipmentFortunately for both our ferrous and nonferrous customers alike Butech Bliss can provide equipment and technical services for nearly every element of the hot strip Hot Cold Rolling Mill Equipment Manufacturers

Metals Nidec Industrial

•Hot Strip Mills •Plate Mills •Steckel Mills Hot Rolling Mills for Long Products •Bar Wire Rod Mills •Section Mills •Rail Mills wrapper roll and jumping control) Hot and cold leveller control • Speed Master • Shear (flying, dividing, trimming) control • Basic FunctionsManjira has over 20 years experience in producing Hot Strip Mill Terminal Equipments as per Customers Designs and Drawings and manufactured and supplied the following terminal equipments for Hot Strip Mills: JSW Steels Ltd, Bellary: Down Coiler Pinch Roll and Wrapper Roll Assemblies Coil Box Transfer Arms and Coil Box Guides with Roller TablesStrip Processing Lines Cold Rolling Mills Product Range We at Jatindra Engineering Corporation are Manufacturer of Hot Rolling Mills, Continuous Galvanizing Lines, Rolling Mill Auxiliaries, Hot Strip Rolling Mills and Bending Metalwork Machines since 1975 in Jhilmil Colony, DelhiJatindra Engineering Corporation Product Range

Products thyssenkrupp

Hot strip thyssenkrupp's hotrolled portfolio extends from mild and structural steels to thermomechanically rolled highstrength PERFORM® grades for cold forming Hotrolled steel is available pickled and unpickled in a variety of dimensionsA method and apparatus for removing oxide scale from the surface of hotrolled stainless steel strip comprises uncoiling the steel strip coil, removing the coil bias and cracking the surface scale in a first scalebreaking apparatus, flattening the strip by removing edge wave and center buckle to a flatness approaching table top flat, the tolerable deviation therefrom depending upon the gauge Method and apparatus for descaling hot rolled across the web times roll radius This means the torque driving the unwind shaft must decrease at a linear ratio, relative to roll diameter, as an unwind roll decreases in size, through a machine run, to keep tension constant Conversely, the torque driving the rewind shaft must increase at a linear ratio, relative to roll diameter, as a rewind THE MECHANICS OF TENSION CONTROL Converter