mining and processing gypsum

2023-05-25T21:05:28+00:00

gypsum mining and processing procedures

gypsum mining and processing procedures The British Gypsum mining process The process starts by extracting gypsum rock deposits from the ground using a ‘JOY mine cutter’ that scores away at the face of the gypsum rock2 天前 Gypsum is commonly associated with rock salt and sulfur deposits It is processed and used as prefabricated wallboard or as industrial or building plaster, used in cement manufacture, agriculture and other uses Gypsum Mining IMAR 7 th Edition Most of the world’s gypsum is produced by surfacemining operationsGypsum Mining Processing Equipment Flow Chart (PDF) Gypsum Mining Production Processing and Marketing gypsum in the country ranges between 05 to 06 million tons per annum Mining of gypsum is being done by the private sector Gypsum is also needed both for the lining of canal and distributaries’ and Mining And Processing Gypsum kwiatkowskiskorypl

gypsum mining and processing vinsdescopainsch

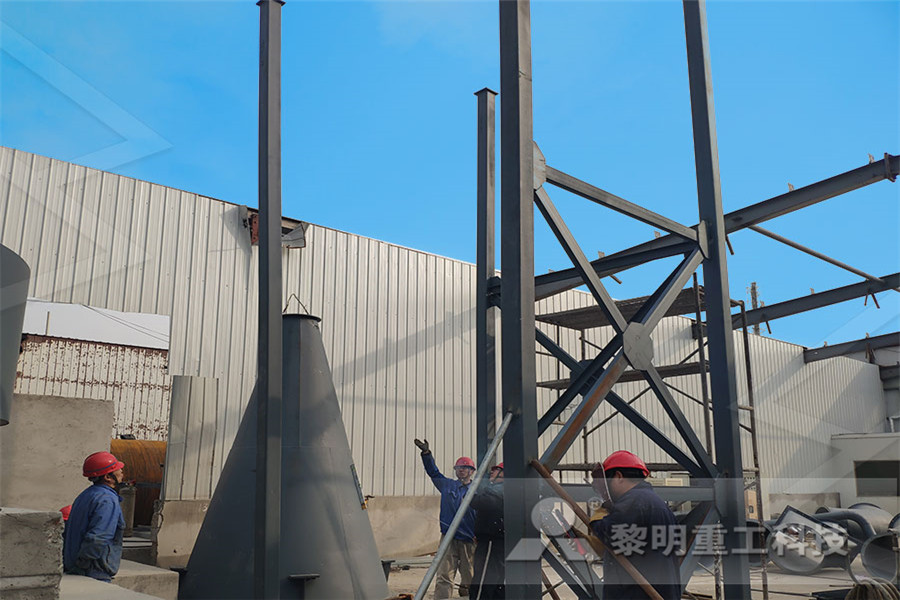

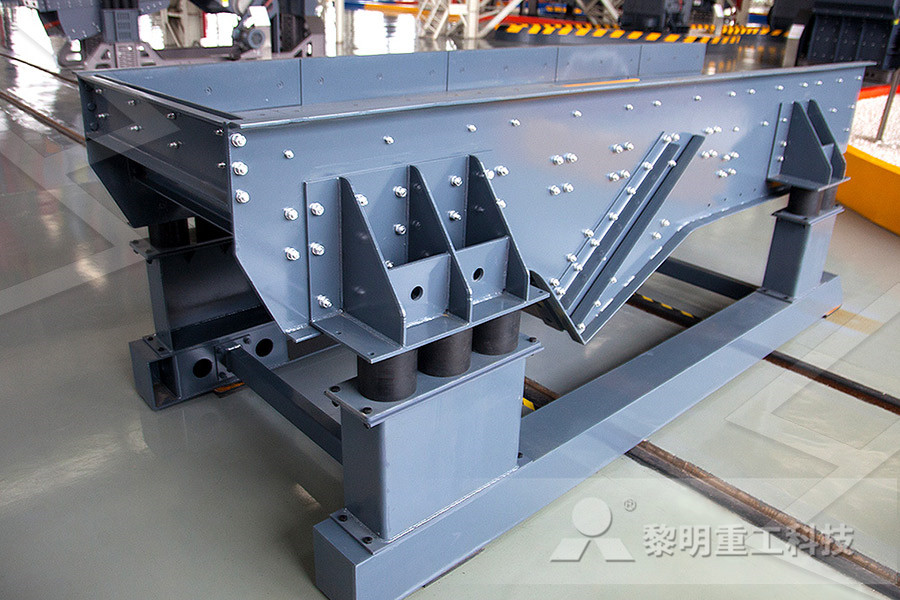

gypsum mining and processing (PDF) Gypsum Mining Production Processing and The process technology of the plant includes from extraction of gypsum to crushing, sifting, calcinations, grinding, mixing, testing and eventually packaging The machinery and equipment required forCurrent production of gypsum in the country ranges between 05 to 06 million tons per annum Mining of gypsum is being done by the private sector Gypsum is also needed both for the lining of canal and distributaries’ and for the correction of low quality water from tubewells(PDF) Gypsum Mining Production Processing and Gypsum processing system five processes According to the technical requirements, gypsum production line is usually divided into five parts, which are broken system, material storage and conveying system, grinding system, calcined system, and electric control systemGypsum crushing processingLIMING Mining and

Processing and Drying Gypsum

Drying Gypsum Drying is an essential in processing gypsum, whether mining or pelletizing Gypsum dryers work as moisture control solutions A rotary dryer is used to reduce the moisture content of the gypsum Lifting flights inside the rotating drum shower the gypsum through a heated air stream, drying the material as it moves through the dryer The process starts by extracting gypsum rock deposits from the ground using a ‘JOY mine cutter’ that scores away at the face of the gypsum rock This is then broken up and transported to the surface It’s homogenising timeThe British Gypsum mining processGypsum Processing, Pelletized (Pelletised) Gypsum The best way to preserve gypsum processing equipment is to keep up with routine maintenance Gypsum These synthetic gypsum pellets were agglomerated in FEECO's lab facility on a disc pelletizer Synthetic Gypsum pellets, pelletized (pelletised) synthetic gypsumGypsum Processing FEECO

Mining and Processing the World’s Mostmined

2671 million tons of gypsum were mined in 2016, a steady increase from 2581 million tons in 2012 China is the world’s largest producer, accounting for 130 million tons in 2016 For more information about mining and processing gypsum processing the ore Gypsum Mining And Processing Procedures The role of drying in gypsum mineral processing after gypsum ore is extracted from mines or quarries it is crushed and stockpiled as needed if the gypsum ore's moisture content is greater than 05 weight percent then the material requires drying a gypsum dryer is commonly used to reduce the moisture content of the ore to the gypsum mining and processing proceduresGypsum Mining Process Gypsum processing equipment differs significantly in scale and level of technology some plants produce one or two tonnes per day using lowcost manual technologies, some other plants of a thousand tonnes per day that are highly mechanized and capable of producing different types and grades of gypsum plaster or plaster boardsthe mining process of gypsum

OVZ Application Gypsum Mining and Processing

OVZ Application Gypsum Mining and Processing Gypsum is a common, soft, evaporative, sedimentary mineral that forms mostly as transparent, flattened crystals Primary commercial operations are in Brazil, Pakistan, Jamaica, Iran, Thailand, Spain, Germany, Italy, England, Ireland, Canada, and the US Its uses are plentiful and varied as The British Gypsum mining process The British Gypsum mining process Date: 14 December 2015 Have you ever wondered how Thistle Plaster is made? Ever been working on a job and wondered where it is the plaster you’re using comes from? Well here’s the answerThe British Gypsum mining process Gypsum Gypsum is one of the raw materials available in abundance in the earth and it is the most sulfuric mineral spread in nature in one of its mineral forms or sedimentary rock and it interferes with the mineral anhydrite (anhydrous calcium sulfate) and is present with dolomite, clay and limestone and is gray or white in color and tends to reddish sometimes and it may be Its presence on the Gypsum Abydos Mining

Gypsum Department for Energy and Mining

Gypsum used for plaster manufacture usually contains at least 90% CaSO 4 2H 2 O, a maximum of 002% NaCl (salt), and approximately 2% acid insolubles Another major use of gypsum is in the cement industry, where it is added at the rate of 2–5% to cement clinker prior to final grinding to retard the setting rate of concrete GYPSUM MINING AND PROCESSING IN NIGERIA: THE OPPORTUNITY Home → Investment Opportunities in Nigeria → GYPSUM MINING AND PROCESSING IN NIGERIA: THE OPPORTUNITY In mining, Nigeria is known to have records of occurrences tin, columbite, tantalite, lead and zinc In fact, mining in Nigeria he said to have started with mining of tin ore in 1905GYPSUM MINING AND PROCESSING IN NIGERIA: THE Processing Gypsum into a Soil Amendment When applying gypsum to soil, a pelletized form is ideal Pelletized gypsum is easy to apply, mixes well with other inputs, and delivers nutrients effectively The uniform sizing of pelletized gypsum also prevents gaps in application coverageProcessing Gypsum for Use in Soil Amendments

Gypsum Minerals Education Coalition

Gypsum Gypsum is a mineral found in crystal as well as masses called gypsum rock It is a very soft mineral and it can form very pretty, and sometimes extremely large colored crystals Massive gypsum rock forms within layers of sedimentary rock, typically found in thick beds or layers It is liberated from its natural state most commonly by surface mining To get the gypsum ore into a state where it can be sold for its many uses, it is crushed to size using DDCSizers, FeederBreakers, Hammermill Crushers, Jaw Crushers or Roll Crushers and stockpiled to await further processing5 Things You Didn't Know About Gypsum McLanahangypsum processing the ore Gypsum Mining And Processing Procedures The role of drying in gypsum mineral processing after gypsum ore is extracted from mines or quarries it is crushed and stockpiled as needed if the gypsum ore's moisture content is greater than 05 weight percent then the material requires drying a gypsum dryer is commonly used to reduce the moisture content of the ore to the gypsum mining and processing procedures

gypsum mining and processing procedures

Gypsum Mining And Processing Mining And Processing Of Gypsum Gypsum mining and processing tambinh gypsum drying is a technique used as part of the gypsum beneficiation processn mineral processing, beneficiation separates the wanted mineral from unwanted material using a Chat Onlinegypsum mining and processing (PDF) Gypsum Mining Production Processing and The process technology of the plant includes from extraction of gypsum to crushing, sifting, calcinations, grinding, mixing, testing and eventually packaging The machinery and equipment required forgypsum mining and processing vinsdescopainschGypsum Mining Process Gypsum processing equipment differs significantly in scale and level of technology some plants produce one or two tonnes per day using lowcost manual technologies, some other plants of a thousand tonnes per day that are highly mechanized and capable of producing different types and grades of gypsum plaster or plaster boardsthe mining process of gypsum

Gypsum Mining And Processing Procedures MC

Gypsum Mining And Production Process Gypsum production processand and gypsum typically are mined in a moist or wet condition by open pit excavation or by dredgingfter mining, the sand and gypsum materials are transported to the processing plant by suction pump, truck, Gypsum Gypsum is one of the raw materials available in abundance in the earth and it is the most sulfuric mineral spread in nature in one of its mineral forms or sedimentary rock and it interferes with the mineral anhydrite (anhydrous calcium sulfate) and is present with dolomite, clay and limestone and is gray or white in color and tends to reddish sometimes and it may be Its presence on the Gypsum Abydos Mining Drying Gypsum Drying is an essential in processing gypsum, whether mining or pelletizing Gypsum dryers work as moisture control solutions A rotary dryer is used to reduce the moisture content of the gypsum Lifting flights inside the rotating drum shower the gypsum through a heated air stream, drying the material as it moves through the dryerProcessing and Drying Gypsum

Mining and Processing the World’s Mostmined

2671 million tons of gypsum were mined in 2016, a steady increase from 2581 million tons in 2012 China is the world’s largest producer, accounting for 130 million tons in 2016 For more information about mining and processing these minerals, visit the Gypsum Gypsum is a soft sulfate mineral, composed of calcium sulfate dihydrate It is used in fertilizer and is the main material used to produce drywall, plaster, as well as blackboard and Gypsum mine production top countries 2020 Statista Gypsum and Anhydrite – Horton High School time as technological innovations in mining and manufacturing occur and new products The mining and processing of gypsum in China are labor intensive enriched halo in the gypsum near the anhydrite–gypsum contact The processing technology (enrichment) of gypsum