molybdenum flotation introduction

2023-10-03T22:10:31+00:00

molybdenum flotation introduction

Mineral Processing 101 : Molybdenum Ore Beneficiation , Introduction , One of the primary sources for molybdenum is the by product recovery of molybdenite by flotation from bulk copper/ molybdenum concentrat For this flotation system a number of different reagents are used, including alkali sulfides, Nokes reagents, cyanides, chemical oxidants, and/or thermal treatment Introduction Molybdenum is a kind of strategic metal in the industry and medicine, is also of essential element for human body and plant But with the continuous exploitation of the global resources, the high grade ore was being depleted, and the rich ore had been unable to meet the supply needsFlotation technology of refractory lowgrade This paper introduces the most commonly used molybdenum flotation flowsheet, together with the introduction of the flotation chemistry Many different types of flotation cells are used in modern moly plants, and each type of flotation cell has its own unique advantages suited for Molybdenum Flotation Circuit and Flotation Cells

Molybdenum Flotation Process,Molybdenum

Molybdenum Dressing Production Line Introduction Molybdenum dressing production line is useds to extract molybdenum from raw ores Why choose out products 1 Easytouse All devices throught out the whole line are easy to operate 2 Environment friendly Coppermolybdenum flotation process can adopt preferential flotation, partial bulk flotation and bulk flotation process In production, partial bulk flotation and bulk flotation processes are often used in coppermolybdenum, which can separate coppermolybdenum mixed concentrate, then separate copper and molybdenum respectivelyIntroduction of Molybdenum Mineral Processing The most important minerals of molybdenum are molybdenite (MoS2), wulpherite (PbMoO4), and molybdite (MoO3) However, for molybdenum production from ores containing molybdenum in the first step, enrichment is required Therefore, the flotation Enrichment of Molybdenum and Fluorite by Flotation of

(PDF) Treatment of process water from molybdenum

N 2 flotation During flotation with nitrogen it can be anticipated that the same type of reactions occur as during conditioning However, it was observed during testwork that only minor changes in pH, redox and COD occurred during flotation provided that introduction of air was minimisedThe flotation method is ednomolybdenum ore, including grinding ore and collective flotation of copper and molybdenum in alkaline environment, created lime, characterized in that the collective flotation is carried out in the presence of the collector AeroMX 3601 and the expander, then the bulk flotation concentrate after evaporation and desorption heated slurry to 4060°With live steam in the presence Method of flotation of copper molybdenum ores Treatment of process water from molybdenum flotation Ikumapayi Fatai Kolawole1, JanEric Sundkvist2 and NilsJohan Bolin3 1Division of Mineral Processing and Metallurgy, Luleå University of Technology, SE971 87 Luleå, Sweden, 23Division of Process Technology, Boliden Mineral AB, SE936 81 Boliden, Sweden, janericsundkvist@boliden,Treatment of process water from molybdenum flotation

remove molybdenum by flotation Mining

Molybdenum – Wikipedia, the free encyclopedia Molybdenum has a bodycentered cubic crystal structure a flotation process to recover molybdenite from ores; flotation remains the primary isolation process To completely remove it from the solution, Mineral Processing 101 : Molybdenum Ore Beneficiation , Introduction , One of the primary sources for molybdenum is the by product recovery of molybdenite by flotation from bulk copper/ molybdenum concentrat For this flotation system a number of different reagents are used, including alkali sulfides, Nokes reagents, cyanides, chemical oxidants, and/or thermal treatment molybdenum flotation introduction With the steady increase of molybdenum demand worldwide and the favorable molybdenum market, many technological innovations on both process and equipment have been developed and applied in many modern molybdenum plants around the world This paper introduces the most commonly used molybdenum flotation flowsheet, together with the introduction of the flotation chemistryMolybdenum Flotation Circuit and Flotation Cells

Flotation technology of refractory lowgrade

1 Introduction Molybdenum is a kind of strategic metal in the industry and medicine, is also of essential element for human body and plant But with the continuous exploitation of the global resources, the high grade ore was being depleted, and the rich ore had been unable to meet the supply needsMolybdenum Dressing Production Line Introduction Molybdenum dressing production line is useds to extract molybdenum from raw ores Why choose out products 1 Easytouse All devices throught out the whole line are easy to operate 2 Environment friendlyMolybdenum Flotation Process,Molybdenum INTRODUCTION Fluorite (CaF2) is an important fluorine mineral, which is mostly used for the production of Therefore, the flotation method was applied Molybdenum usually occurs as molybdenite in nature and enrichment of molybdenum is much easier in comparison to other ores with high yield Molybdenum has different constituent in mineralsEnrichment of Molybdenum and Fluorite by Flotation of

(PDF) Treatment of process water from molybdenum

N 2 flotation During flotation with nitrogen it can be anticipated that the same type of reactions occur as during conditioning However, it was observed during testwork that only minor changes in pH, redox and COD occurred during flotation provided that introduction of air was minimised Copper–Molybdenum Sulphide Ore by Flotation Zhixiang Chen 1, Guohua Gu 1,*, Shuangke Li 1,*, Introduction In the case of copper–molybdenum separation, chalcopyrite (CuFeS2) and molybdenite (MoS2) are the main copper and molybdenum minerals found in complex sulfide ores The natural hydrophobicityCopper–Molybdenum Sulphide Ore by FlotationThe flotation method is ednomolybdenum ore, including grinding ore and collective flotation of copper and molybdenum in alkaline environment, created lime, characterized in that the collective flotation is carried out in the presence of the collector AeroMX 3601 and the expander, then the bulk flotation concentrate after evaporation and desorption heated slurry to 4060°With live steam in Method of flotation of copper molybdenum ores

INVESTIGATION OF EFFECTIVE PARAMETERS FOR

Keywords: Flotation, copper, molybdenum, recovery Introduction About 50% of the world's molybdenite (MoS 2) concentrate is evolved from its primary ores and the rest as a lowgrade concentrate byproduct of copper, uranium and tungsten mining Molybdenite reserves of Handbook of Flotation Reagents Chemistry, Theory and Practice: Flotation of Sulfide Ores by Srdjan M Bulatovic • ISBN: • Publisher: Elsevier Science Technology Books • Pub Date: April 2007Handbook of Flotation Reagents WebsThe flotation method is ednomolybdenum ore, including grinding ore and collective flotation of copper and molybdenum in alkaline environment, created lime, characterized in that the collective flotation is carried out in the presence of the collector AeroMX 3601 and the expander, then the bulk flotation concentrate after evaporation and desorption heated slurry to 4060°With live steam in Method of flotation of copper molybdenum ores

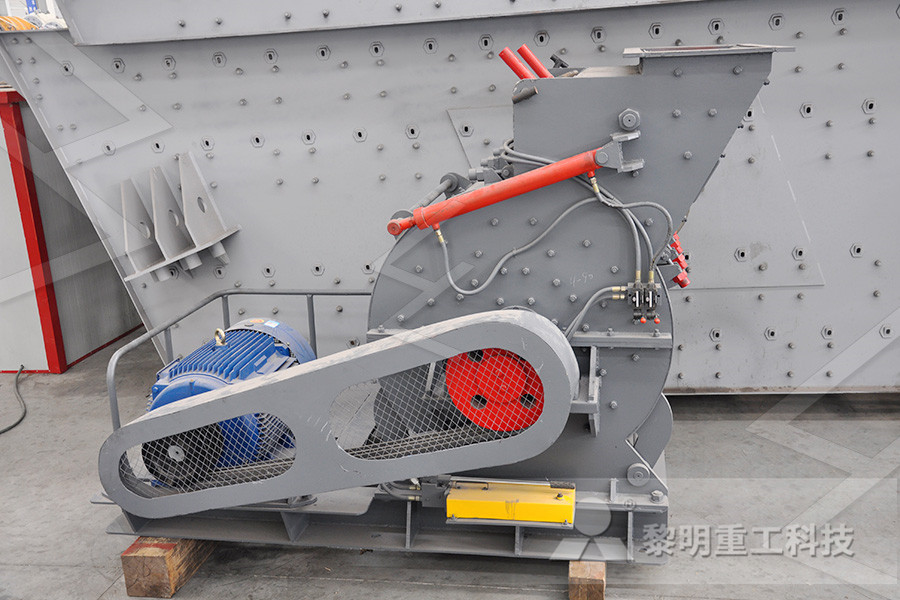

Molybdenum Dressing Production Line Yantai

Introduction Application Molybdenum dressing production line can be used for single or refractory molybdenum with complex properties, close sulfide minerals symbiosis and fine particle distribution Process Flotation for the molybdenum ore with less copper ,usually use mixed and priority process Molybdenum – Wikipedia, the free encyclopedia Molybdenum has a bodycentered cubic crystal structure a flotation process to recover molybdenite from ores; flotation remains the primary isolation process To completely remove it from the solution, remove molybdenum by flotation MiningThe milled ore/gangue powder is mixed with a liquid and aerated in the flotation step The less dense ore rises in the froth to be collected, while the gangue sinks to be discarded Flotation separates the metallic minerals from the gangue this way and – in the case of copper/ molybdenum ores – separates molybdenite from copper sulphideMolybdenum Processing IMOA

Optimization of a Copper/Molybdenum Flotation Circuit

Optimization of a Copper/Molybdenum Flotation Circuit by Depressing Pyrite from the Rougher Flotation Stage Using Different Scheme of Reagents A thesis submitted in partial fulfillment of the requirements for the degree of Master Of Science in Metallurgical Engineering by Wander A Valderrama Dr Carl C Nesbitt/Thesis Advisor May 728 Introduction Flotation is one of the most widely used methods for mineral concentration The separation process is a surface predict copper and molybdenum grades and their recoveries 4 Result and Discussion A back propagation feed forward neural network with two hidden layers was constructed for modeling of theEstimation of Copper and Molybdenum Grades and Keywords: Flotation, copper, molybdenum, recovery Introduction About 50% of the world's molybdenite (MoS 2) concentrate is evolved from its primary ores and the rest as a lowgrade concentrate byproduct of copper, uranium and tungsten mining Molybdenite reserves of INVESTIGATION OF EFFECTIVE PARAMETERS FOR

Technical Resource Document: Extraction and

The flotation feed is sent to the flotation plant, where the ore is passed through hydraulic sizing and over screens and separated into three sizes Different flotation methods are used for each size material The flotation products are then combined with the pebble product and shipped offsite to Copper flotation process Mining – separating minerals by flotation Measurement made easy — Introduction The flotation process can separate a required mineral such as copper, nickel, molybdenum or zinc from ore Flotation can separate this mineral from waste materials or from another mineral The process starts with crushed ore A ball millpH/ORP measurement Copper flotation process There are many factors affecting the flotation process, including nonadjustable factors and adjustable factorsAmong them, nonadjustable factors refer to the ore property, adjustable factors mainly include grinding fineness, pulp concentration, pulp pH value, reagent system, pulp temperature, water quality, flotation time and so onEight Factors Affecting the Flotation Process Xinhai