Crushing Equipment Maintenance

2022-04-28T09:04:45+00:00

crushing equipment maintenance in Mozambique

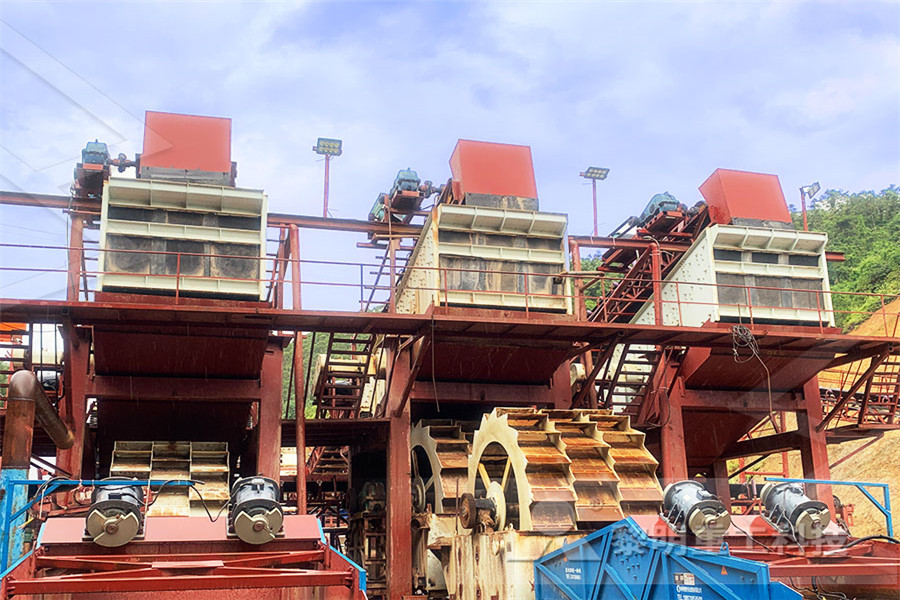

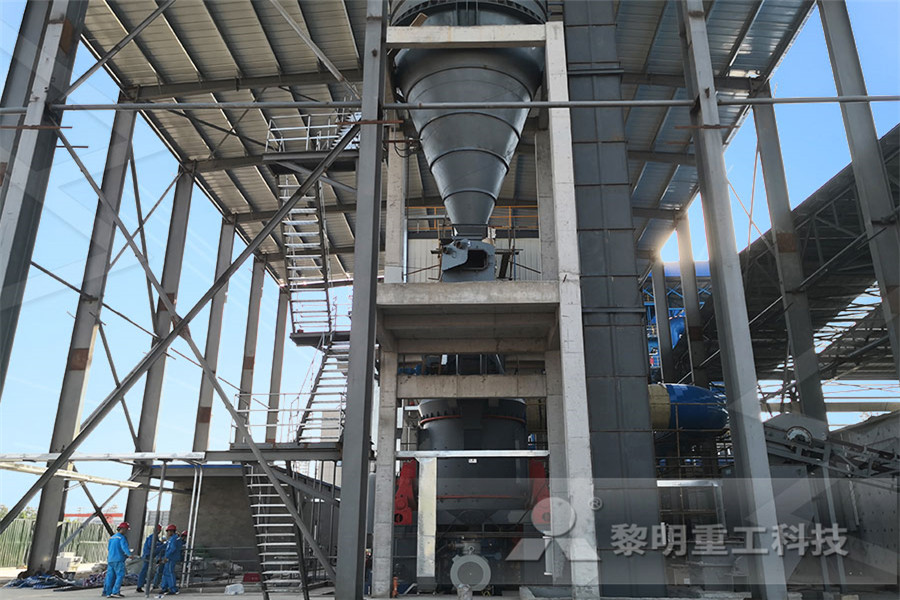

Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals, Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimum Crushing, Grinding, Feeding, Screening, Separation, and Filtration Equipment Maintenance RPM’s rebuild and repair services are well placed for fully re Crushing, Grinding, Feeding, Screening RP MaintenanceCrushing Plant and Equipment (CPE) are industry leaders providing endtoend services for all your mining, quarrying and recycling needs We offer our clients a wide range of services such as The supply of new / used / reconditioned jaw and cone crushers, screens, feeders and conveyors Repairs and maintenance to existing plant and equipmentCrushing Plant Equipment Leaders in Mining, Quarrying

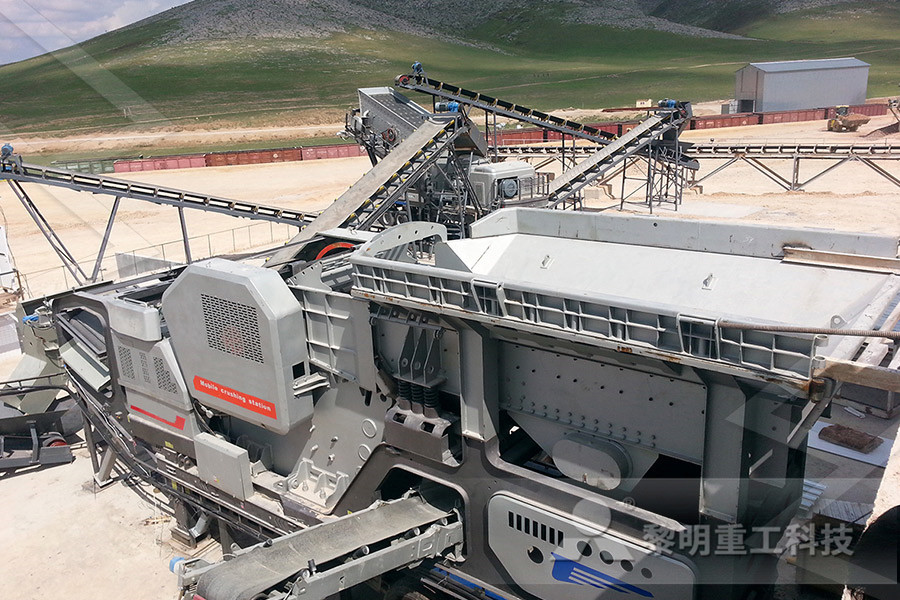

The Installation and Maintenance of Mobile Crushing Plant

The Installation and Maintenance of Mobile Crushing Plant by adminaimixcrusher As long as you purchase our equipment, we will send special technicians to help you to install the machine and give you online guide pattern of crushing plant of complex mining equipment • To estimate the reliability and maintainability characteristics of crushing plant in absolute quantitative terms • To identify the critical subsystems which require further improvement through effective maintenance policies to enhance the operational reliability of mining operation,Reliability and maintainability analysis of crushing Engineered spare and wear parts as well as maintenance and optimization services are designed with decades of experience in different crushers and crushing processes The parts are durable and easy to maintain, maintenance is quickly available, and the optimization services help in getting most out of new or used equipment – or the entire crushing processCrushing Outotec

Stone crusher, mining machine, rock crusher, jaw crusher

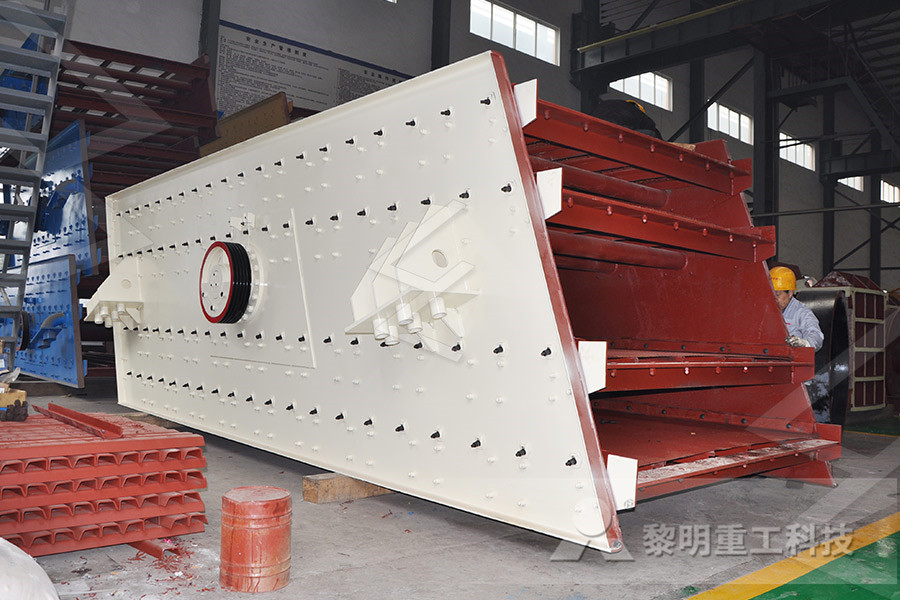

What needs to be done for maintenance of cone crusher Cone crushers are widely favored by customers due to their large crushing ratio and high efficiency performance characteristics However, we often do not know how to maintain and maintain the machine during use, which will easily cause the machine to fail Developing a special method for maintenance of Critical Equipments is necessary for improving maintenance quality and reducing operating costs The combination of corrective preventative and condition based maintenance will required to apply for Critical Equipments This type of maintenance policy and strategy will improveCritical Equipment MaintenanceCrushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals, Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimumcrushing equipment maintenance in Mozambique

Primary Crushing Equipment Maintenance Limestone

Primary Crushing Equipment Maintenance Limestone First primary crushing the limestone of the original material passes through the silo it is uniformly fed by the vibrating feeder and transported to the jaw crusher for primary crushingNoone can see into the future with perfect accuracy, but Sandvik’s global experts often come close By regularly analyzing your crushing and screening equipment – as well as your operational and maintenance trends and your supplies of wear and spare parts – Sandvik can increase capital availability across your entire plantMaintenance and Support — SRP Sandvik Group The regular maintenance of parts Maintenance plays an important role in the whole operation Maintaining the crusher machine rationally can maximize the working efficiency, and here are the maintenance tips of the main parts Concave During the crushing process, there is a great impact on the concave which makes the filled zinc layer be out Cone Crusher Tips of Operation and Regular

Crushing and Screening Equipment Guide Wheeler

Without crushing and screening equipment, none of this production would be possible — and road, building, and bridge construction and maintenance would be forced to come to a halt While there can be cases made for all pieces of construction equipment, perhaps the most compelling is for crushing equipment and screening equipment, which so From the day we started our Western Australian operations in 2010, we have created an unmatched team of highly dedicated and widely experienced industry professionals Originally focusing on maintenance and equipment rentals for the mobile crushing industry, we have quickly evolved into a complete mineral handling contractorHome CSS Crushing Service Solutions This means taking an engineering or design approach to the elimination of risk in crushing equipment Before the risk elimination question can be asked, it is important to understand that repairs, maintenance, relocating crushing spreads and unplugging crushers are major causes of Crushing and Screening Safety is our #1 Priority

Choosing the Right Rock Crushing Equipment

This rock crushing equipment uses compressive force to fracture the rock and this happens when the mantle makes contact with the bowl during gyration Gyratory crushers are often built into a cavity in the ground and are mostly used to crush rocks that have high compressive strength 2 According to the function, it is divided into crushing type and sand making type: the concrete crushing and screening machine includes a combination of crushing equipment such as jaw crusher, cone crusher and impact crusher The sand making type is mainly equipped with sand making machine and hammer sanding machine2 Types of Concrete Crushers critical equipment, it is necessary to maintain the critical parts of that equipment So it is also important to identify the critical parts The parts directly affect the performance of equipment performance and operations are known as critical parts of equipments Each equipment overall performance depend upon the condition of bearingsCritical Equipment Maintenance

Repairs Maintenance Crushing Plant Equipment

Crushing Plant and Equipment also have a fully equipment service vehicle to carry out repairs and work on site All of our service team are fully qualified with all the appropriate training and clearances for on the site jobs We can perform anything from maintenance, Preventive crusher maintenance Outotec crushing equipment and process specialists use ore characterization data, comprehensive plant surveys, and historical operational data to develop site specific models for your comminution processes These models are used in simulation studies along with extensive industrial and consulting Crusher services Outotec The Installation and Maintenance of Mobile Crushing Plant by adminaimixcrusher As long as you purchase our equipment, we will send special technicians to help you to install the machine and give you online guideThe Installation and Maintenance of Mobile Crushing

jaw crushing equipment maintenance manual

Jaw Crusher Operating And Maintenance Manual Pdf Jaw Crusher Operating And Maintenance Manual Pdf Product capacity : 52200t/h Max Feeding Size : mm Output Size : 10400mm This series of jaw crusher belongs to stone crushing equipment which is widely used in the works of metallurgy, mining, cement, chemistry, refractory and ceramics as well as highway construction and water conservancyCrushing Equipment TimR T10:39:47+08:00 Project Description From compact units suitable for restricted spaces, all the way up to large, high volume units Crushing Equipment Mineral Processing Solutions From the day we started our Western Australian operations in 2010, we have created an unmatched team of highly dedicated and widely experienced industry professionals Originally focusing on maintenance and equipment rentals for the mobile crushing industry, we have quickly evolved into a complete mineral handling contractorHome CSS Crushing Service Solutions

Crushing Equipment Amcast

AMCAST is Inventing the future of the mining and aggregate processing industries with technologysavvy rock crushing equipment This website stores cookies on your computer These cookies are used to collect information about how you interact with our website and allow us to remember youEase of Maintenance InPit Crushing and Conveying (IPCC) Auxiliary Equipment Mining equipment for any situation Primary crushing: Products Primary crushing Primary crushing plants are the first step in material processing and/or link between mining truck and belt conveyor, train or road Read More Primary crushing TAKRAF GmbH This rock crushing equipment uses compressive force to fracture the rock and this happens when the mantle makes contact with the bowl during gyration Gyratory crushers are often built into a cavity in the ground and are mostly used to crush rocks that have high compressive strengthChoosing the Right Rock Crushing Equipment

Rock crushing equipment for sale Eastman Rock

Most aggregate producers are well acquainted with the selection of crushing equipment and know it is possible to select a piece of equipment based solely on spec sheets and gradation calculations Still, theoretical conclusions must always be weighed against practical experience regarding the material at hand and of the operational, maintenance