know how on cement plant

2019-08-30T21:08:45+00:00

A TEC provides knowhow for cement plant erection in

A TEC optimizes the construction process with an eye for detail and an understanding of the whole In addition A TEC employees lead a supplier quality assurance and ensure a smooth process The plant, which will have the capacity to produce two million t of cement Cement manufacturing: components of a cement plant This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc For Cement manufacturing components of a cement plantDetailed Project Report (DPR) on cement plant Present Market Position and Expected Future Demand, Technology, Manufacturing Process, Investment Opportunity, Plant Economics and Project Financials comprehensive analysis from industry covering detailed reporting and evaluates the position of the industry by providing insights to the SWOT analysis of the industryProject Report on cement plant, Feasibility Report, How

All You Need To Know About How Cement Bathing Plant

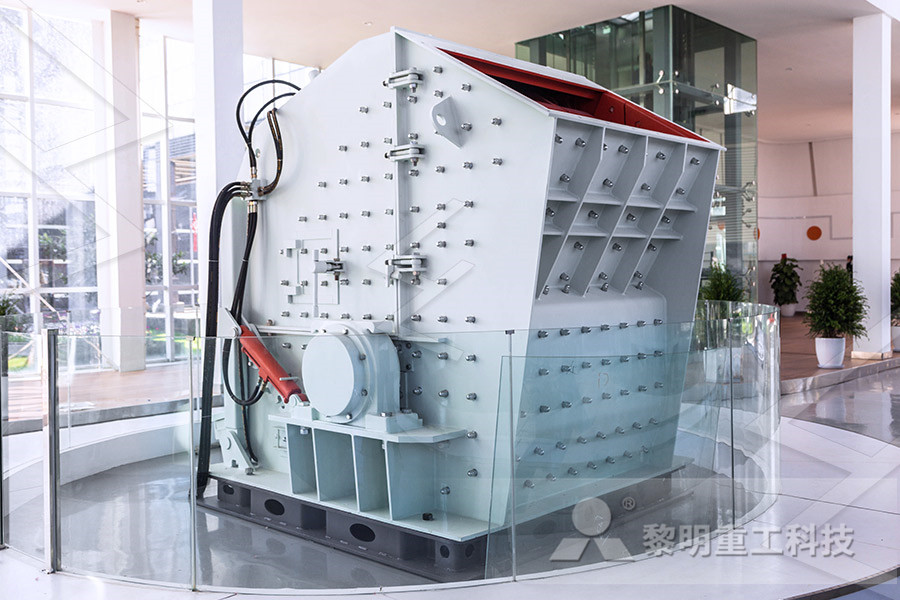

Read on as we dive into how cement bathing plant works If you didn’t already know, there are two types of concrete plants These being the dry mix plant and the wet mix plant The names already suggest the dry concrete plant whips up a dry mix before dispatching The materials are firstly weighed and then placed into the mixer There are various types of cement crusher on the market, including jaw crusher, cone crusher, hammer crusher, impact crusher, and etc AGICO Cement can provide all types of cement crusher Our cement crusher can fully crush the raw material, reduce feed size into the mill, and increase the reaction of raw material in the following cement manufacturing process, reduce the energy Cement Euipment Overview Cement Making Cement PlantDetailed Project Report (DPR) on cement plant (3200 tpd) Present Market Position and Expected Future Demand, Technology, Manufacturing Process, Investment Opportunity, Plant Economics and Project Financials comprehensive analysis from industry covering detailed reporting and evaluates the position of the industry by providing insights to the SWOT analysis of the industryProject Report on cement plant (3200 tpd), Feasibility

Project Report on cement plant using clinker (instead of

Detailed Project Report (DPR) on cement plant using clinker (instead of mining limestone and gypsum) Present Market Position and Expected Future Demand, Technology, Manufacturing Process, Investment Opportunity, Plant Economics and Project Financials comprehensive analysis from industry covering detailed reporting and evaluates the position of the industry by providing insights to the SWOT Cement plant capacities will remain in the typical range of between 15 and 25 Education and knowhow development Sustainable cement production relies on well educated and well trained employees, be it in cement plants or along the value chain as far as the construction companies using the product The challenge of reducing energy and raw Sustainable cement production—present and future According to the data we know, the total cost of a cement plant is estimated to be US$ 75 to US$ 100 per ton One thing to be clear, this is just an estimation, in the real cement plant building, the cement factory cost is affected by various factors, including the significant difference in cost of land, availability of limestone mines, etcHow Much Does It Cost To Start A Cement Plant?

Preheater In Cement Plant, Cyclone Preheater, Cement

The cyclone preheater, also called cement preheater, suspension preheater, is a kind of preheater in cement plantAs the core equipment of dry method cement production line, cyclone preheater use suspension preheating to preheat and partly decompose the cementraw mix, shorten the length of rotary kiln, fully mix raw mix and hot air in the kiln, increase heat exchange rate, which promote the A TEC optimizes the construction process with an eye for detail and an understanding of the whole In addition A TEC employees lead a supplier quality assurance and ensure a smooth process The plant, which will have the capacity to produce two million t of cement per year, will be finished by the beginning of 2017 atecltdA TEC provides knowhow for cement plant erection Part of modern cement plant operation is the usage of alternative fuels A TEC can offer the complete AF system for nearly any kind of solid and liquid waste materials including material handling A TEC provides knowhow for cement plant erection

All You Need To Know About How Cement Bathing

Read on as we dive into how cement bathing plant works If you didn’t already know, there are two types of concrete plants These being the dry mix plant and the wet mix plant The names already suggest the dry concrete plant whips up a dry mix before dispatching The materials are firstly weighed and then placed into the mixerCement Plant Basic Concepts of Manufacturing Learn the basic concepts of Ordinary Portland Cement fabrication, necessary equipment, the relationship between raw material crushing, pre blending, raw material grinding, blending, kiln operation and cement grinding This training is Cement plant ABC – an introduction to cement Cement Plant In the category of CEMENT, we deal in both types of Cement OPC and PPC, and providing in all size packaging also provides Bulker Know More TMT BAR fe 500D In the category of TMT we are dealing in any size of TMT Bars Like 6mm 8mm, 10mm and up to 40mm Know MoreMajor Cement Plant Top 10 Cement Manufacturers

Cement Plant Manufacturers, Cement Plant Machines,

Cement manufacturing is An integrated process undergone multiple stages, Our Cement Plant division holds the deep knowldege of all type of cement plant processes related to raw material to packed bags production We delivers best quality cement projects most reliable, cost effective, energy savings and provide best cement, We have supplied and installed various cement plant projects in { "Term": " suggestions", "productName":"Products", "productFamily": "Product families", "download": "Downloads", "content": "More content" }Holcim cement plant: Distance sensors always know NTNSNR bearings are designed for the cement industry: ensuring optimum profitability, by reducing the costs associated with the use of bearings, throughout the process ensuring comprehensive service and support to prevent problems before they occur: onsite technical assistance , lubrication solutions , onsite training and fault diagnosisBearings for cement plants NTN SNR

About Us – JSW Cement

KNOW MORE Vijaynagar JSW Cement’s first plant was set up at Vijayanagar, Bellary in Karnataka with a capacity of 060 MTPA in 2008 Its capacity was boosted to 360 MTPA in the year 2017 and was enhanced further to 40 MTPA in the year 2019 Vijayanagar Works has a 150acre campus and is located next to the JSW Steel complex cement plant cost what is the cost of a new cement plant of 2 MTPA? what is the cost of erection for the same cost of iron for the same? rajesh Reply Know the answer to this question? Join the community and register for a free guest account to post a replycement plant cost Page 1 of 2 A TEC optimizes the construction process with an eye for detail and an understanding of the whole In addition A TEC employees lead a supplier quality assurance and ensure a smooth process The plant, which will have the capacity to produce two million t of cement per year, will be finished by the beginning of 2017 atecltdA TEC provides knowhow for cement plant erection

All You Need To Know About How Cement Bathing

Read on as we dive into how cement bathing plant works If you didn’t already know, there are two types of concrete plants These being the dry mix plant and the wet mix plant The names already suggest the dry concrete plant whips up a dry mix before dispatching The materials are firstly weighed and then placed into the mixerCement Plant Basic Concepts of Manufacturing Learn the basic concepts of Ordinary Portland Cement fabrication, necessary equipment, the relationship between raw material crushing, pre blending, raw material grinding, blending, kiln operation and cement grinding This training is Cement plant ABC – an introduction to cement Cement plant laboratories check each step in the manufacture of portland cement by frequent chemical and physical tests The labs also analyze and test the finished product to ensure that it complies with all industry specifications The most common way to manufacture portland cement is through a dry method The first step is to quarry the How Cement Is Made

ABB in cement manufacturing

bution in your cement plant, turn to ABB We offer the broadest range of high, medium and low voltage equipment for switching and distributing electrical power to the cement plant Solutions are engineered for safety, flexibility and security to keep operations running day and night, including emergency power generation and Cement Plant Process and Instruments Used 1 Plant Process Instruments Used Ravi Roy DeptInstrumentation 2 What is cement? The term cement is commonly used to refer to powdered materials which develop strong adhesive qualities when combined with waterCement Plant Process and Instruments Used Its a fact that most of the cement industry experts know that this industry emit huge CO2 and also also they have found some alternative fuels also, but still lot of natural resources are wasted which can reduce clinker percentage of a cement, We have to address general public in a simple language which we can educate them about cement types which have developed with less clinkerEmissions from the Cement Industry Columbia

Cement Industry Loesche

The roller grinding mill technology, patented in 1928 and continuously developed since then, has become synonymous with Loesche‘s pioneering engineering knowhow CEMENT BLAST FURNACE SLAG CEMENT RAW MATERIALPRISM CEMENT Prism Cement a division of Prism Johnson Limited is one of India’s leading integrated Building Materials Company, with a wide range of products from cement, readymixed concrete, tiles and bath products Prism Johnson Limited is an IMS Certified Company (ISO 9001:2008, ISO 14001:2004, ISO 18001:2007, SA 8000:2008 ISO 50001:2011)Prism Cement The cement industry relies on power Power and fuel costs account for ~30% of the price of cement when it’s sold As a result, power and fuel have a major impact on the company’s operating Mustknow: The cost elements of cement Market