mining primary crusher material transfer

2020-07-26T10:07:23+00:00

Mining Primary Crusher Material Transfer

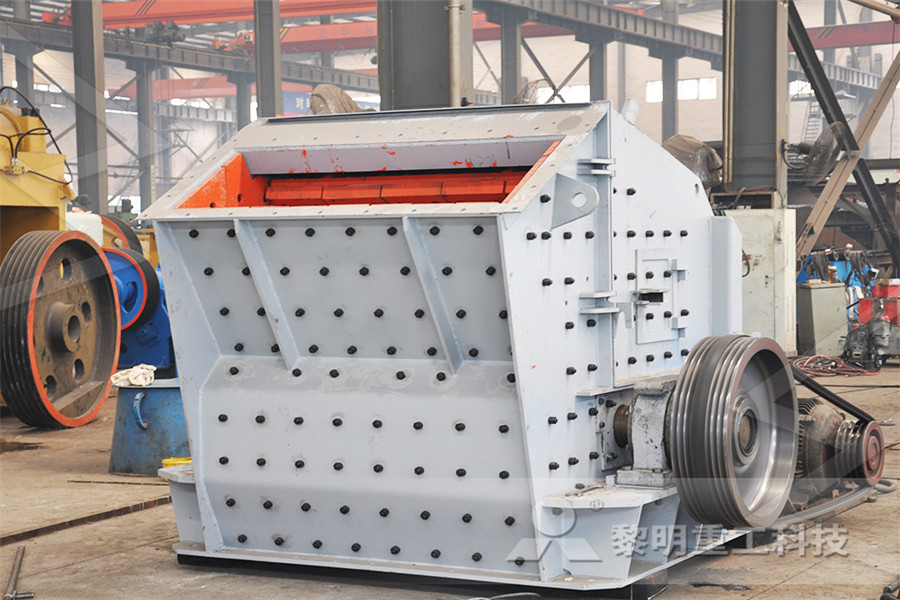

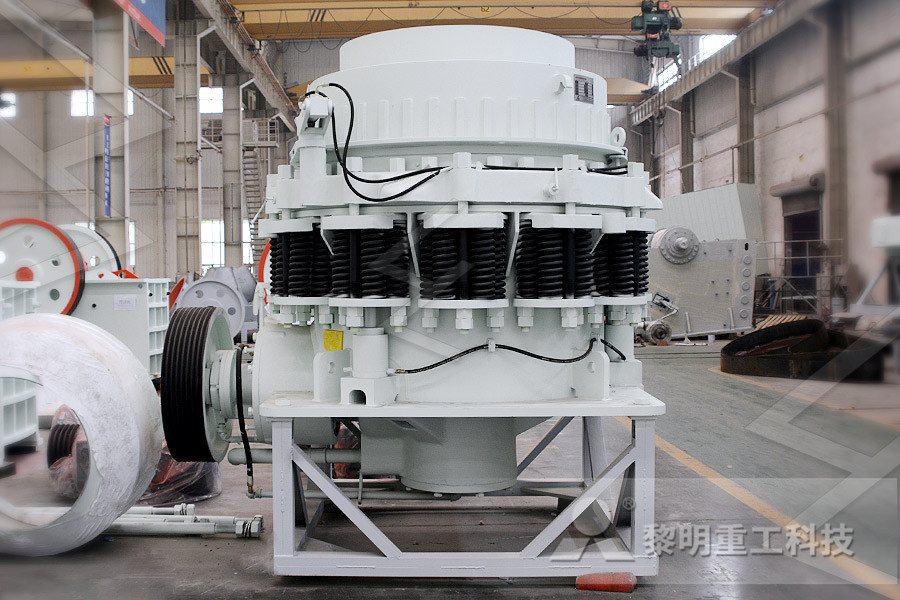

Mining Primary Crusher Material Transfer Primary And Secondary Crushing In Mining And Quarries gyratory crushers can be used for primary or secondary crushinghe crushing action is caused by the closing of the gap between the mantle line movable mounted on the central vertical spindle and the concave liners fixed mounted on the main Mining Primary Crusher Material Transfer mining primary crusher material transfer mining primary crusher material transfer Crushing is the process of transferring a force amplified by mechanical advantage Crushing devices hold material between two parallel or tangent solid surfaces, anMining Primary Crusher Material Transfermining primary crusher material transfer – Coal processing Find the Right and the Top mining primary crusher material transfer for your coal handling plant! liming, a mining machines manufacturer in china focus on your local Primary Crusher Mining Crusher Mills, Cone Crusher,

Primary Crusher Relocation Engineering Penta

Industry: Mining and Metals Solution: Materials Handling A gold mining client needed to relocated their 2500stph existing primary crusher to extend quarry life The relocation required alignment of the new crusher location with an existing radial stacker and material handling systemG Lodewijks, A Newman, in Handbook of Powder Technology, 2001 21 The primary crusher The primary crusher is located in the quarry and consists of a McLanahan 48″x72′ Shale King Crusher rated at 1,000 TPH (Tons Per Hour) The driving flywheel has a diameter of 25 meters and is motor driven through six vbelts The capacity of the primary crusher had to be increased to 1,250 TPH to Primary Crusher an overview ScienceDirect Topics The term “primary crusher,” by definition, might embrace any type and size of crushing machine The term implies that at least two stages of crushing are involved, but in many cases the machine which performs the function of initial crusher is the only crusher Primary Crushing 911 Metallurgist

purpose of automation of mining crusher Prominer

Mining Equipment: Primary Crusher – ecn automation In the mining processes, after the blasting and transport in dump trucks, the first stage of the crushing process start, its Material is loaded into the crusher bin (1) by trucks or loaders Prior to entering the jaw crusher the rock moves across a grizzly (2) The grizzly has a series of slots in it allowing the smaller pieces of rock to fall through (3) The remaining oversized material passes through the jaw crusher (4) and is sized down to less than 200mmCrushing and conveying – Waihi GoldIn most crushing installations a jaw crusher takes care of primary crushing Plants with very high capacities that are common in mining and less popular in aggregates production, normally use a primary gyratory crusher When the processed material is easy to crush and not very abrasive, an impact crusher may be the best choice for primary crushingCrushers All crusher types for your reduction needs

Major Mines Projects Mining Intelligence and News

The primary crusher discharge conveyor accelerates material to match the speed for transfer onto the 14 km long coarse ore stockpile feed overland conveyor The coarse ore stockpile feed overland conveyor is equipped with a weightometer to measure crushed ore tonnage A hydraulically operated rock breaker mounted on the perimeter of the dump mining primary crusher material transfer – Coal processing Find the Right and the Top mining primary crusher material transfer for your coal handling plant! liming, a mining machines manufacturer in china focus on your local Primary Crusher Mining Crusher Mills, Cone Crusher, Industry: Mining and Metals Solution: Materials Handling A gold mining client needed to relocated their 2500stph existing primary crusher to extend quarry life The relocation required alignment of the new crusher location with an existing radial stacker and material handling systemPrimary Crusher Relocation Engineering Penta

Crushing and conveying – Waihi Gold

Material is loaded into the crusher bin (1) by trucks or loaders Prior to entering the jaw crusher the rock moves across a grizzly (2) The grizzly has a series of slots in it allowing the smaller pieces of rock to fall through (3) The remaining oversized material passes through the jaw crusher (4) and is sized down to less than 200mmMining Equipment: Primary Crusher – ecn automation In the mining processes, after the blasting and transport in dump trucks, the first stage of the crushing process start, its purpose of automation of mining crusher Prominer Jaw Crusher Overview Jaw Crusher is one of the main types of primary crushers in a mine or ore processing crusher plant and also is one of the most widely used crushing equipment in mining industry This series of jaw crusher can reach the crushing ratio of 46 and the shape of final product is even Because it is primary crusher, Jaw crusher is designed for long life service with minimum Primary Crusher

Mining Methods VS Underground Crusher Location

The common yardstick by which we will measure all these mining methods is the basic decentralized crusher concept, beyond which portability, or the degree thereof, will be the special and distinguishing feature Accordingly, underground hardrock mines are divided into three major groups, listed below with their distinguishing characteristicsThe primary crusher discharge conveyor accelerates material to match the speed for transfer onto the 14 km long coarse ore stockpile feed overland conveyor The coarse ore stockpile feed overland conveyor is equipped with a weightometer to measure crushed ore tonnage A hydraulically operated rock breaker mounted on the perimeter of the dump Major Mines Projects Mining Intelligence and NewsPrimary Crushing Ore material delivered to the ROM pad will be stored in nominated ROM dump pads adjacent to a permanent ROM wall for primary crushing Ore will pass through a primary crusher, resulting in a product stream of coarse ore less than 250 mm in diameter to be delivered to the OPF Conveyor to OPFMajor Mines Projects Mining Intelligence and News

Mothae Kimberlite Mine, Lesotho Mining Technology

The material is extracted from the bin using a vibrating grizzly feeder (VGF) The VGF undersize and hybrid crusher product is discharged into the primary crusher product transfer conveyor, from where it is discharged onto the scrubber feed transfer conveyor The primary benefit to customers will be a very specific focus on transfer points involving two pioneers in material handling technologies “CCC’s focus and engineering expertise in chute design will be complemented by Martin’s experience and innovation in product design and service,” Huhn continuedConveyors in Mining International Miningmining primary crusher material transfer – Coal processing Find the Right and the Top mining primary crusher material transfer for your coal handling plant! liming, a mining machines manufacturer in china focus on your local Primary Crusher Mining Crusher Mills, Cone Crusher,

Primary Crusher Relocation Engineering Penta

Industry: Mining and Metals Solution: Materials Handling A gold mining client needed to relocated their 2500stph existing primary crusher to extend quarry life The relocation required alignment of the new crusher location with an existing radial stacker and material handling systemIn most crushing installations a jaw crusher takes care of primary crushing Plants with very high capacities that are common in mining and less popular in aggregates production, normally use a primary gyratory crusher When the processed material is easy to crush and not very abrasive, an impact crusher may be the best choice for primary crushingCrushers All crusher types for your reduction needs Material is loaded into the crusher bin (1) by trucks or loaders Prior to entering the jaw crusher the rock moves across a grizzly (2) The grizzly has a series of slots in it allowing the smaller pieces of rock to fall through (3) The remaining oversized material passes through the jaw crusher (4) and is sized down to less than 200mmCrushing and conveying – Waihi Gold

purpose of automation of mining crusher Prominer

Mining Equipment: Primary Crusher – ecn automation In the mining processes, after the blasting and transport in dump trucks, the first stage of the crushing process start, its The crushed material is then put on the surge pile where it is taken to the secondary crushing plants on the site to be reduced down to a variety of sizes Mining dust control In the past, Linwood has used water hoses and spray bars to help control dust both at the crusher and at transfer pointsCase Study: Crusher Dust Control at Limestone Mine The common yardstick by which we will measure all these mining methods is the basic decentralized crusher concept, beyond which portability, or the degree thereof, will be the special and distinguishing feature Accordingly, underground hardrock mines are divided into three major groups, listed below with their distinguishing characteristicsMining Methods VS Underground Crusher Location

Conveyors in Mining International Mining

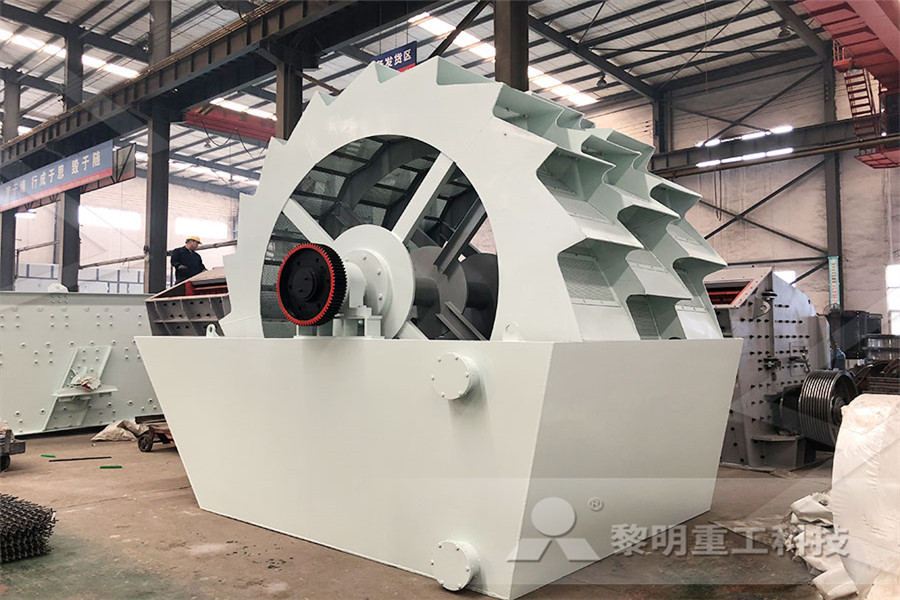

The primary benefit to customers will be a very specific focus on transfer points involving two pioneers in material handling technologies “CCC’s focus and engineering expertise in chute design will be complemented by Martin’s experience and innovation in product design and service,” Huhn continuedExcavate and transfer the raw material into a plant Material is reduced in a jaw crusher Material is screened either to the endproduct pile or to a crusher to further reduction Material is further reduced in a cone crusher The endproduct of your plant Crushing Screening 3 stages Primary and secondary crushers in an open plant with two My Plant Planner Outotec