iron ore mining processes

2023-08-26T07:08:03+00:00

Iron Mining Process Minnesota Iron

Iron Mining Process From blasting to crushing to separation – more than 85% of the iron mined in the United States is mined in northeastern Minnesota to make our nation’s steel Blasting Taconite is a very hard rock Using explosives, the taconite is blasted into Mining and processing of iron ore involves coarse crushing and screening Iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening This is usually so efficient that lower grade ore can be treated especially when the magnetite is quite coarseIron ore mining process and iron ore mining MINING AND PROCESSING: Iron ore mining can be broadly divided into two categories namely 1) manual mining which is employed in small mines and 2) mechanized mining is suitable for large iron ore mines Manual mining method is normally limited to float ores and small mines Mining of reef ore is also being done manually on a small scaleIron Ore Mining Techniques Metal Extraction

Life cycle assessment of iron ore mining and

The extraction of iron ore involves surface (openpit) or underground mining techniques (please refer to Chapter 7 (Stace, 2015) on Iron Ore Extraction Techniques) The LCA boundary used in this study is shown in Figure 204The mining method selected depends on a variety of factors, including the nature and location of the deposit and the size, depth, and grade of the deposit The iron ore production system target of this study is composed of three units: Mining, Processing and Support System The mining activity can be described by operations of dismantling, loading and transportation of ore and wasteA Life Cycle Assessment study of iron ore mining IOC's production process begins in the mine with drilling and blasting The crude ore is loaded into trucks, which dump the material into the loading pockets or into the inpit crusher located in the Luce pitOur Mining Process Iron Ore Company of Canada

Mining of Iron Ores – IspatGuru

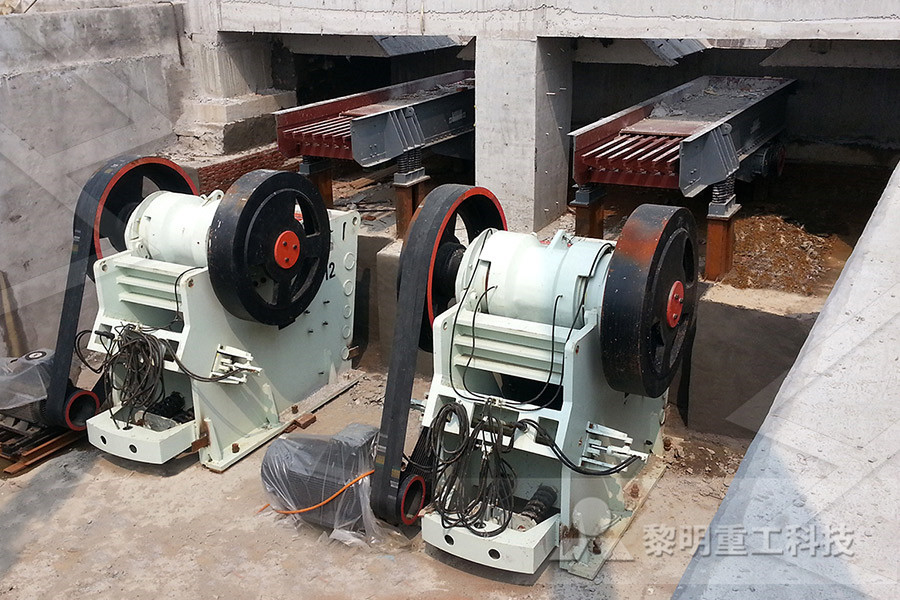

Mining of Iron Ores satyendra; March 14, 2014; 0 Comments ; Hematite, Iron ore, mines, mining, Mining of Iron Ores Iron ore is a type of mineral and rock from which metallic iron is extracted economically This ore is normally rich in iron oxides and vary in color from dark grey, bright yellow and deep purple to rusty redProduction Process of Iron Ore Generally, the processing of iron ore needs several processing stages, including crushing, grinding, ore beneficiation, concentrating, drying, etc The equipments for iron ore beneficiation is consisted of Jaw Crusher, Ball Iron Ore,Production Process of Iron Ore,Iron Ore The deep mining of iron ore is unusual in the modern era, but in northern Sweden, ore is mined from considerable depth largely aided by the application of automation and remote control equipment Kiruna has been chosen as the example for a more detailed review of Iron ore extraction techniques ScienceDirect

Iron processing Britannica

Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned Included in this article also is a discussion of the mining of iron and of its preparation for smelting Iron (Fe) is a relatively dense metal with a The middlings produced by three processes are moved to screening process The tailings of wet magnetic separation will be discharged directly Grinding and fine crushing After the second crushing, iron ore particles are moved to secondary crushing and the first ball mill grinding With fine ore particles, it is more efficient to upgrade iron oreIron ore mining process and iron ore mining Iron ore is an important raw material for iron and steel production enterprises After crushing, grinding, magnetic separation, gravity concentration etc, gradually we can get iron from natural minerals (iron ore) It is the mineral aggregates that contain iron or iron compounds which can be used economically Production Process of Iron Ore Iron Ore,Production Process of Iron Ore,Iron Ore

Processes Involve In Iron Ore Mining

Processes Involve In Iron Ore Mining The process of the extraction of iron is carried out by the following steps Concentration of ore Calcination or Roasting of ore Reduction of ore Read more stages involved in extraction of iron ore Send Message Get a QuoteIron ore is an economic mineral aggregate containing iron elements or compounds Four Kinds of Hematite Ore Dressing Processes Hematite (Fe2O3) is a kind of weak magnetic mineral, and its crystal belongs to the oxide mineral of hexagonal crystal systemIron Ore Processing, Process of Iron Mining, Iron Iron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron oreIron Ore Processing Prominer (Shanghai) Mining

How is Iron Ore Processed – From Ore to Steel Iron

Iron Ore Processing – From Ore to Steel Starting from the raw materials and going all the way to the finished product, our company handles coal and iron ore mining in order to provide a complete range of service offerings and steel products Since we are the largest mining and steel company in the world, we are proud to announce that in 2014 we managed to produce more than seven point seven The difference between the above processes of the extraction of iron ore is that the coenobium direction between the magnetite and the sulfide is different • For the weak magnetic separation – froth flotation process, the coenobium mainly enters iron mon Iron Ore Extraction Processes When the iron ore is extracted from the mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is The Six Main Steps of Iron Ore Processing Multotec

Mining of Iron Ores – IspatGuru

Mining of Iron Ores satyendra; March 14, 2014; 0 Comments ; Hematite, Iron ore, mines, mining, Mining of Iron Ores Iron ore is a type of mineral and rock from which metallic iron is extracted economically This ore is normally rich in iron oxides and vary in color from dark grey, bright yellow and deep purple to rusty red Iron processing, use of a smelting process to turn the ore into a form from which products can be fashionedIncluded in this article also is a discussion of the mining of iron and of its preparation for smelting Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties It constitutes 5 percent by weight of the Earth’s crust, and it is the Iron processing BritannicaIron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron oreIron Ore Processing Prominer (Shanghai) Mining

Brief Introduction on Iron Ore Mines Mining Process

There are many kinds of iron ore mines, and the iron ore mine mining processes are also different Based on the nature of different iron ore mines, we choose the suitable iron ore mine mining process to achieve the best ore processing effect marketing@ytxinhai 0086 When the iron ore is extracted from the mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is The Six Main Steps of Iron Ore Processing Multotec Mining of Iron Ores satyendra; March 14, 2014; 0 Comments ; Hematite, Iron ore, mines, mining, Mining of Iron Ores Iron ore is a type of mineral and rock from which metallic iron is extracted economically This ore is normally rich in iron oxides and vary in color from dark grey, bright yellow and deep purple to rusty redMining of Iron Ores – IspatGuru

Iron Ore Pelletizing Process: An Overview

Iron Ore Pelletizing Process: An Overview Sandra Lúcia de Moraes, The iron ore is mined mostly from open pit deposits through mining operations and the raw product, run of mine, is subjected to mineral processing Thus, the material is exposed to a ironmaking processes The particle size distribution of iron ore is a very important It involves the dry recovery of iron ore fines and super fines from mining wastes, low grade run of mine (ROM), or compact itabirite Whereas existing dry separation processes work for New dry iron ore processing technology Australian Iron ore is the primary raw material used to make steel Steel is strong, longlasting and costefficient – making it perfect for everything from washing machines to cars, bridges and skyscrapers According to the World Steel Association, steel is the most commonly used alloy in the world Global Iron Ore Rio Tinto

Crushing and milling Mining of mineral resources

The first iron mining techniques used charcoal which was mixed with iron ore in a bloomery When heating the mixture and blowing air (oxygen) in through bellows, the iron ore is converted to the metal, iron The chemical reaction between iron oxide and carbon is used here to produce iron metal The iron ore deposits began forming when the first organisms capable of photosynthesis began releasing oxygen into the waters This oxygen immediately combined with the abundant dissolved iron to produce hematite or magnetite These minerals deposited on the sea floor in great abundance, forming what are now known as the "banded iron formationsIron Ore: Sedimentary Rock Pictures, Definition 24 Production Costs for NAICS 21221—Iron Ore Mining, 1997 211 25 Worker Productivity by Plant Size for Facilities in NAICS 21221—Iron Ore Mining To better control emissions of hazardous air pollutants (HAPs) during these processes, EPA expects that additional emission control equipment will be installed for indurating furnacesTaconite Iron Ore NESHAP Economic Impact Analysis