Modernization And Improvement Of Cement Grinding

2021-06-10T11:06:46+00:00

Modernization And Improvement Of Cement Grinding

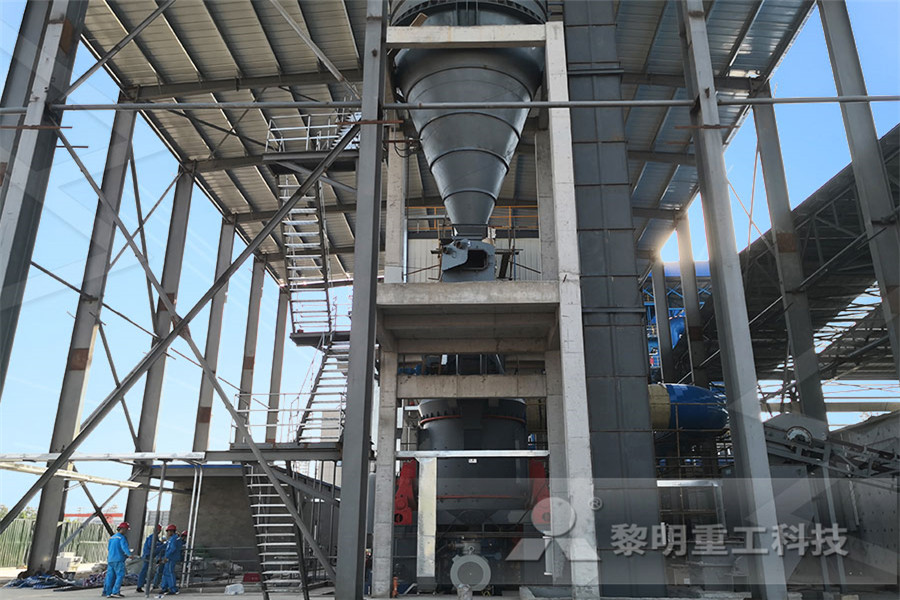

The use of grinding aids allows interesting results to be obtained, in terms of production cost reduction and improvement of cement properties 2 Beside the positive effects on reduction of agglomeration and improvement of mi ll efficiency, grinding aids have a strong chemical effect on cement hydration,Modernization And Improvement Of Cement Grinding These modernization projects aim at increasing the capacity with limited capital cost while reducing operating costs Considering these constraints, modernization of a cement grinding unit with implementation of a high efficiency classifier is a very profitable opportunityModernization And Improvement Of Cement Grindingmodernization and improvement of cement grinding As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of mineralsmodernization and improvement of cement grinding

Grinding plant modernization Fives in Cement

Lowering the carbon footprint The installation of the FCB TSV™ Classifier, by reducing the bypass and the corresponding overgrinding, enables a reduction in the specific electrical energy consumptionThis has a direct positive effect on the carbon footprint Furthermore, the cement quality improvement enables either a reduction of Blaine fineness (thus reducing the specific grinding energy Field report of a cement plant modernisation with the compact 2Stage Koesep air classifier During 2015 the Austrian cement manufacturer Schretter Cie GmbH Co KG modernised its grinding process The former system with a high pressure grinding roll (HPGR) working in a pregrinding mode was upgraded to a grinding circuit with an HPGR in semi Field report of a cement plant modernisation with the The major modernization was carried out by the Belgian developer of process optimization solutions for abrasive and impact applications, Magotteaux (on terms of EPC contract) The modernization of Shymkentcement’s grinding facility was carried out in two stages: the three 3×14 m cement mills underwent modernization first, and the other three Grinding Facility Modernization at Shymkentcement

MODERNIZATION OF THE TECHNOLOGICAL CYCLE OF

Abduraxmonov SM and at all Modernization of the technological cycle of cement grinding 2018, V22, №2 pp174177 SHORT MESSAGES 174 Scientifictechnical journal (STJ FerPI, ФарПИ ИТЖ, НТЖ ФерПИ, 2018, TImprovement of performance and energy consumption by retrofitting modern components Pointing out ways of modernization like gypsum precalcining for cement mills, conversion to coal firing or replacement of classifier with the highefficiency versionMill upgrading and modernization Gebr Pfeiffer of modernization projects and which were used for the figures in this article 2 The TSV™ classifier For grinding in the cement production process the fine fraction is the finished product and the coarse fraction is returned to the grinding mill for reprocessing Getting more from the cement ball mill with the Fives FCB

The influences and selection of grinding chemicals in

1 Introduction Cement is an important material that its consumption has been steadily increasing depending on the construction business growing all around the globe However, the manufacturing process is known as energy intense since the energy utilization is about 110–150 kW h per tonne of cement varying with the process modernization and raw materials used Improvement of performance and energy consumption by retrofitting modern components Pointing out ways of modernization like gypsum precalcining for cement mills, conversion to coal firing or replacement of classifier with the highefficiency versionMill upgrading and modernization Gebr Pfeiffer modernization and expansion work Further downtimes for the gearless drive retrofit were not necessary The twostage grinding circuit consists of a 40 ft SAG (semiautogenous grinding) mill with a 20 MW gearless drive designed by Siemens Drive Technologies and two seriesconnected 10 MW geardriven ball millsMinerals Focus the Magazine for the Cement Industry

how to improve cement mill production

RESULTS • $1,500,000 per year improvement in cement production CEMENT GRINDING OPTIMISATION Lehigh Cement Company's modernization of its Union Bridge, MD, plant has integrated process control and energy management to improve Grinding plant modernization Fives in Cement Minerals Lowering the carbon footprint The installation of the FCB TSV™ Classifier, by reducing the bypass and the corresponding overgrinding, enables a reduction in the specific electrical energy consumptionThis has a direct positive effect on the carbon footprint Furthermore, the cement quality improvement enables either a reduction of Blaine french company into cement grinding chemicals in It was designed for 5 rotary kilns lines by the Project Institute "Novorosgiprocement" (USSR) Between 1965 and 1998 there were various reconstructions and renovations including modernization of grinding equipment, reconstruction and improvement of rotary kilns, cement grinding mills Kant Cement Plant

which type of crusher use in the lafarge cement

modernization and improvement of cement grinding modernization and improvement of cement grinding cement grinding units in apminingbmwHome > Grinding > cement grinding units in ap cement Inquiry Online Tarmac Official Site Tarmac is the UK s leading sustainable building materials group Our innovative products solutions and services 1 Introduction Cement is an important material that its consumption has been steadily increasing depending on the construction business growing all around the globe However, the manufacturing process is known as energy intense since the energy utilization is about 110–150 kW h per tonne of cement varying with the process modernization and raw materials used The influences and selection of grinding chemicals in Continuous modernization ensures the maintenance, improvement or expansion of production equipment and helps us to remain competitive and become more environmentally friendly and efficient Investments are planned well in advance in order to build up appropriate reserves and, for example, to plan for planned machine downtimes in the productionInvestment in the future WALZEN IRLE GmbH

Grinding Seminar Christian Pfeiffer

Our Motivation We are constantly developing and want to become even better and more efficient In order to continue to be a partner to our customers over the long term, we want to share all the knowledge we have gained from various projects and our own development: Christian Pfeiffer invites its customers each year to a fourday seminar in Beckum on this topicRehabilitation and modernization of two (2) wet kiln lines (1100 t/d clinker) (20062007) Rehabilitation and modernization of three (3) oil shale/coal grinding system (20 t/h mill) (eg new bag filters with extinguish system) Improving of four (4) cement mills (eg new feeders, new transmissions and motor (1,6 MW), new bag filters) ANL Engineering Oymodernization and improvement of cement grinding cement grinding units in apminingbmwHome > Grinding > cement grinding units in ap cement grinding Inquiry Online 200 Tph Stone Cone Crusher Errecters In Maharashtragrinding concrete manufacturers in chennai

Minerals Focus the Magazine for the Cement Industry

modernization and expansion work Further downtimes for the gearless drive retrofit were not necessary The twostage grinding circuit consists of a 40 ft SAG (semiautogenous grinding) mill with a 20 MW gearless drive designed by Siemens Drive Technologies and two seriesconnected 10 MW geardriven ball millsmodernization and improvement of cement grinding modernization and improvement of cement grinding cement grinding units in apminingbmwHome > Grinding > cement grinding units in ap cement Inquiry Online Tarmac Official Site Tarmac is the UK s leading sustainable building materials group Our innovative products solutions and services which type of crusher use in the lafarge cement modernization and improvement of cement grinding modernization and improvement of cement grinding cement grinding units in apminingbmwHome > Grinding > cement grinding units Inquiry Online GENERAL CONSTRUCTIONAL 1502 Nature of Price (s) twin core Aluminum solid The condition existing when the pole ceases to sustain a load increment aluminum chromite crushing process price

Energy Efficiency Improvement and Cost Saving

Substantial potential for energy efficiency improvement exists in the cement industry and in individual plants A portion of this potential will be achieved as part of (natural) modernization and expansion of existing facilities, as well as construction of new plants in particular regions Still, a relatively large potential for improved energy the measures and experiences of cement plants around the world with these practices and technologies Substantial potential for energy efficiency improvement exists in the cement industry and in individual plants A portion of this potential will be achieved as part of (natural) modernization and expansion ofEnergy Efficiency Improvement Opportunities for Cement Polish cement industry endeavours to reduce CO 2 emissions, most of all, through modernization of cement plants and improvement of energy efficiency, maximum, acceptable increase of waste use as raw materials as well as alternative fuels 51 Reduction of emissions through improvement of energy efficiencyCO2 emissions from Polish cement industry

): Automation solutions for the Cement Industry

Competence for the processes in the Cement Industry 6 The Cement Industry typically produces Portland cement – sometimes also masonry cement Portland cement is a fine, typically gray powder comprised of calcium (from lime), silicates, aluminates (argillaceous), and ferrites, with addition of sulfates Cement plants can operate continuously Holcim Russia plans to invested EUR350m for the modernization of its Volsk plant The project will include the installation of a new semi wetprocess production line with a capacity of 4500tpd, replacing the wet process techniqueHolcim to modernize Volsk cement plant, RussiaResponsible for all kinds of revamps, improvement and optimization inside cement crushing and grinding plants Furthermore we are responsible for the tkIS single maschine sales of apron feeders, screens, crushers, preblending equipments, burner, clinker cooler, cement coolers, separators, ball mills, etc at brownfield cement plantsTim Hücking – Group leader Project / Technical Sales