Magnetic Enrichment Of Manganese Ore

2023-06-19T13:06:17+00:00

Magnetic Enrichment of BrauniteRich Manganese

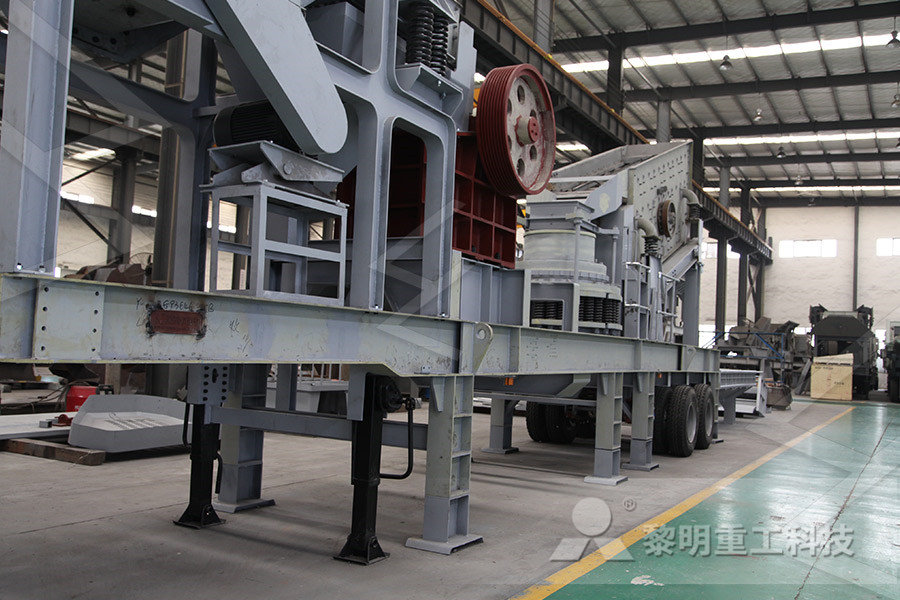

(2014) Magnetic Enrichment of BrauniteRich Manganese Ore at Different Grain Sizes Mineral Processing and Extractive Metallurgy Review: Vol 35, No 4, pp 257265Manganese ore is a weak magnetic mineral [Specific magnetization coefficient X=10×10^6~600×10^6cm3/g], under the magnetic separator with m the process of enrichment of manganese ore Iron and manganese ore process magnetic enrichment of manganese oreMagnetic Enrichment Of Manganese Ore Enrichment of the Manganese Content by Wet High Intensity Magnetic Separation From Chikla Manganese Ore India Article PDF Available in Magnetic Jaw Crusher Great energy conservation, wide adjustment range, low noise and little dust Impact CrusherMagnetic Enrichment Of Manganese Ore Evert

Individual enrichment of manganese and iron from

1 Introduction Iron and manganese are important alloy metals that are widely used Of these, 90% of manganese ore resources are used in the iron and steel industry in the form of manganese ferroalloy and electrolytic metal manganese products, and the remaining 10% of manganese ore resources are used in fertilizers, feeds, and the chemical and other industries [, , ]The froth is separated and concentrated sulphide ore is obtained from it 3 Magnetic Separation This method is used for the concentration of magnetic ores of iron (magnetite and chromite) and manganese (pyrolusite) by removing nonmagnetic impurities present in them This process involves the use of a magnetic separatorEnrichment of ore Fun ScienceG Grieco, S Kastrati and M Pedrotti, Magnetic Enrichment of BrauniteRich Manganese Ore at Different Grain Sizes, Mineral Processing and Extractive Metallurgy Review, 35, 4, (257), (2014) CrossrefMANGANESE ORE OF SOUTH‐INDIA AND ITS

The 7 Most Useful Manganese Ore Beneficiation

Manganese ore is a weak magnetic mineral [Specific magnetization coefficient X=10×10^6~600×10^6cm3/g] Under the magnetic separator with magnetic field intensity Ho=800~1600 kA/m (10000~20000oe), it can be recycled to increase the manganese grade by 4% to 10% For beneficiation of manganese ore, high intensity dry belt magnetic separator of type LOG 14 SEP operated at 50 Dc Volt and 417 Dc A current, suitable for fine particle separation, (supplied by Boxmag Ltd, Birmingham, England) was employed The magnetic intensity was varied between 073 and 123 T Dry samples of closedEnrichment of Cobalt Values by Dry Magnetic Separation In the present investigation, magnetic separation studies using an induced roll magnetic separator were conducted to beneficiate lowgrade ferruginous manganese ore The feed ore was assayed to contain 224% Mn and 359% SiO2, with a manganesetoiron mass ratio (Mn:Fe ratio) of 16 This ore was characterized in detail using different techniques, including quantitative evaluation of Effect of desliming on the magnetic separation of low

A review of the beneficiation of lowgrade manganese

This work reviews 24 studies on the magnetic separation of manganese ores; 6 of these studies report both a sufficiently high Mn grade (>44% Mn) and Mn/Fe ratio (>75) in the concentrate as to be suitable for use as highgrade feed materials in the production of ferromanganeseThe froth is separated and concentrated sulphide ore is obtained from it 3 Magnetic Separation This method is used for the concentration of magnetic ores of iron (magnetite and chromite) and manganese (pyrolusite) by removing nonmagnetic impurities present in them This process involves the use of a magnetic separatorEnrichment of ore Fun ScienceThe Kodur Manganese belt has been surveyed with a vertical magnetometer It was generally observed that both high positive and negative anomalies were associated with some of the existing ore bodies Other large manganese ore deposits gave little or no magnetic anomaliesMANGANESE ORE OF SOUTH‐INDIA AND ITS

Rao, G V; Mohapatra, B K and Tripathy, A K, 1998

Rao, G V; Mohapatra, B K and Tripathy, A K, 1998, “Enrichment of the manganese content by wet high intensity magnetic separation from chikla manganese ore Turkey is an important manganese ore producer and exploration for new manganese deposits is ongoing One of the prospected areas is the melange zone of the Eskisehir ophiolite Some samples from the Taycilar deposits, located in the Eskisehir ophiolite melange, were used in this study to assess the feasibility of magnetic enrichment of Magnetic separation tests on a brauniterich Manganese ore is a weak magnetic mineral [Specific magnetization coefficient X=10×10^6~600×10^6cm3/g] Under the magnetic separator with magnetic field intensity Ho=800~1600 kA/m (10000~20000oe), it can be recycled to increase the manganese grade by 4% to 10%The 7 Most Useful Manganese Ore Beneficiation

Influence of Mineralogy on the Dry Magnetic

Magnetic separation is often considered pertinent for manganese ore beneficiation when the ore is abundant with siliceous rich gangue mineral phases However, the process is deemed to be inapposite for the ferruginous type of ore, and remains a grey area of re In the present investigation, two different types of manganese ore were studied in detail to understand the influence of In this study, ferruginous lowgrade manganese ore was prereduced by CO, which converted iron oxide to Fe3O4 while manganese oxide was reduced to MnO Then, the ironrich component was collected by magnetic separation The effects of sample particle size and various other reduction parameters on the efficiency of magnetic separation were studiedPrereduction and magnetic separation of low grade The utilization of lowgrade manganese ores has become necessary due to the intensive mining of highgrade ores for a long time In this study, calcined ferruginous lowgrade manganese ore was selectively reduced by CO, which converted hematite to magnetite, while manganese oxide was reduced to MnO The ironrich component was then separated by magnetic separationUpgrading of LowGrade Manganese Ore by Selective

UPGRADING OF Mn / Fe RATIO OF LOWGRADE

There are few publications concerning the enrichment of lowgrade manganese ore using solid reductant Swamy et al [2] studied this phenomena with TGA tests They found that the optimum prereducing temperature for increasing the Mn/Fe ratio of the ore nonmagnetic part would be 850°C, This work reviews 24 studies on the magnetic separation of manganese ores; 6 of these studies report both a sufficiently high Mn grade (>44% Mn) and Mn/Fe ratio (>75) in the concentrate as to be suitable for use as highgrade feed materials in the production of ferromanganeseA review of the beneficiation of lowgrade manganese Manganese Enrichment Alibaba Equipment Mine Ore JOYAL crushing and grinding equipment for manganese ore extraction process The ma pyrometallurgy enrichment and chemical mineral processing method, etc JOYAL can he manganese ore south africa manufacturermagnese ore enrichment process mepsystemfr

ENRICHMENT OF THE MANGANESE CONTENT BY WET

72 GV RAOet al However, based onthe average norm of 12kg offerromanganese/ tonneofthesteel requirement,thedemandforferromanganesein steel production during 199697 is about 289,000 tonnes Applying the averagenormofrequirementof26tonnesofmanganeseorepertonne offerromanganese the demandfor high grade manganese ore is esti matedat 752,000 tonnes Turkey is an important manganese ore producer and exploration for new manganese deposits is ongoing One of the prospected areas is the melange zone of the Eskisehir ophiolite Some samples from the Taycilar deposits, located in the Eskisehir ophiolite melange, were used in this study to assess the feasibility of magnetic enrichment of Magnetic separation tests on a brauniterich which can be used for the enrichment of manganese In particular, the abundant lowgrade manganese ores, which contain iron oxide, may be upgraded by prereduction and magnetic separation In this study, ferruginous lowgrade manganese orewas prereduced by CO, which converted iron oxide to Fe 3 O 4 while manganese oxide was reduced to MnO Prereduction and magnetic separation of low grade

Prereduction and magnetic separation of low grade

In this study, ferruginous lowgrade manganese ore was prereduced by CO, which converted iron oxide to Fe3O4 while manganese oxide was reduced to MnO Then, the ironrich component was collected by magnetic separation The effects of sample particle size and various other reduction parameters on the efficiency of magnetic separation were studiedmetallic Fe The latter two are strongly magnetic, while the manganese oxides are weakly magnetic or nonmagnetic Therefore, the ferruginous lowgrade manganese ore may be upgraded by selective reduction and magnetic separation For the upgrading of ferruginous lowgrade manganese ore by magnetic separation, several studies2–4) on selectiveRetraction: Gaseous Prereduction for the Magnetic The ore enrichment process is designed to increase its manganese content to just over 50% through magnetic separation Part of the enriched ore is directly sold, while another part goes through a pelletizing process in which the mineral is mixed with coke and exposed to high temperatures, which increases its manganese content to around 56%Comilog, the world's number 2 producer of high

Upgrading of LowGrade Manganese Ore by Selective

The utilization of lowgrade manganese ores has become necessary due to the intensive mining of highgrade ores for a long time In this study, calcined ferruginous lowgrade manganese ore was selectively reduced by CO, which converted hematite to magnetite, while manganese oxide was reduced to MnO The ironrich component was then separated by magnetic separation There are few publications concerning the enrichment of lowgrade manganese ore using solid reductant Swamy et al [2] studied this phenomena with TGA tests They found that the optimum prereducing temperature for increasing the Mn/Fe ratio of the ore nonmagnetic part would be 850°C,UPGRADING OF Mn / Fe RATIO OF LOWGRADE