vertical roller mills for al grinding

2019-09-20T12:09:07+00:00

vertical roller mills for coal grinding MC World

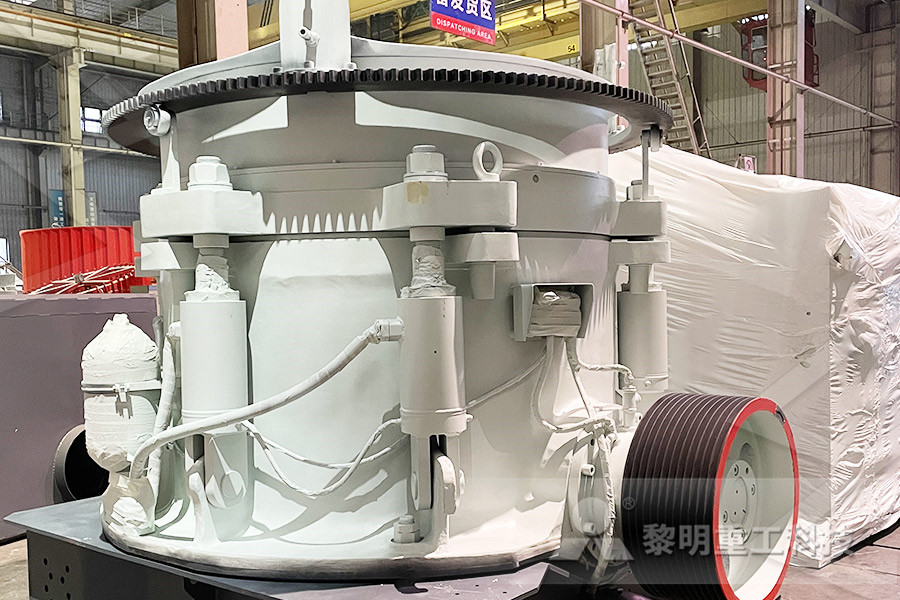

Vertical Roller Mills For Coal Grinding Roller Crusher Vertical Roller Mills For Coal Grinding Industrial, Vertical roller mills vrm can replace ball mills or tube mills used for preparing coal today vrms with capacities up to 50 tph are the dominant technology for coal grinding according to miit grinding media wear in a vrm will only be 5 to 10 gton of coal p Vertical Roller Mills For Coal Vertical coal grinding mill integrates crushing, drying, grinding, powder selection and conveying; It has simple system and compact structure Vertical coal mill covers an floor area about 50% of the coal ball mill with the same specification; Coal vertical mills can work in openair environments, greatly reducing the cost of investment The design of the vertical coal mill system is simple Vertical Coal Mill for Coal Grinding in Cement Plant HLM Vertical Roller Mill HLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology It features in a combination of drying grinding classifying and conveying HLM vertical grinding mill has high grinding efficiency low power consumption large feed size product fineness easy adjustment vertical roller mills for cement coal grinding

Vertical roller mills offer supreme grinding

We have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials It is increasingly used as a solution for efficient grindingVertical roller mills (VRM) can replace ball mills or tube mills used for preparing coal Today VRMs with capacities up to 50 tph are the dominant technology for coal grinding According to MIIT, grinding media wear in a VRM will only be 5 to 10 g/ton of coal powder, as compared to 100 g/ton of coal powder in a vertical mill for coal grinding The vertical roller mills are classified into vertical coa mill and vertical ore mill in the large scale grinding process vertical roller mill used for quartz,gold in mineral beneficiation Vertical roller mills are widely accepted as the most efficient means for grinding cement raw material and clinkercoal mill vertical roller mill Solution for ore mining

Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

Depending on the abrasiveness of the material to be ground and areas to be protected, different wear materials are used on our vertical roller mills The grinding elements are primarily made of alloy cast iron as per DIN 1695, hardfaced cast iron or composite Introduction This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can and are used for other purposes The 3D model in the saVRee database represents a vertical grinding bowl millOther grinding mill types include the ball tube mill, hammer mill, ball and race mill, and , roll and ring millVertical Grinding Mill (Coal Pulverizer) Explained GKLM vertical grinding mill is one advanced powder making mill through our engineer re and experience It is ideal equipment for superfine milling industry which integrated with crushing, drying, grinding and collecting It is widely used in cement, power, metallurgy, chemical, nonmetallic mineralsVertical Grinding Mill, Vertical Roller Mill Powder

vertical roller mill for coal grinding salzgrottesteinch

Vertical Roller Mills for Coal Grinding Industrial Vertical roller mills (VRM) can replace ball mills or tube mills used for preparing coal Today VRMs with capacities up to 50 tph are the dominant technology for coal grinding According to MIIT, grinding media wear in a VRM will only be 5 to 10 g/ton of coal powder, as compared to 100 g/ton Vertical roller mill can replace ball mills or tube mills used for preparing coal Today VRMs with capacities up to 50 tph are the dominant technology for coal grinding Grinding media wear in a VRM will only be 5 to 10 g/ton of coal powder, as compared to 100 g/ton of coal powder in a ball mill Packaging Delivery: Packaging Details China Straight Centrifugal Grinder/Vertical Coal Roller vertical roller mills for coal grinding Vertical roller mills (VRM) can replace ball mills or tube mills used for preparing coal Today VRMs with capacities up to 50 tph are the dominant technology for coal grinding According to MIIT, grinding media wear in a VRM will only be 5 to 10 g/ton of coal powder, as compared to 100 g/ton of coal used vertical roller mills for coal grinding

Vertical Roller Mill Great Wall

Vertical roller mill is mainly used for grinding raw meal, clinker, GGBFS(Ground Granulated Blast Furnace Slag), iron ore, limestone, coal powder, coke powder, coal gangue, fly ash, volcanic ash, gypsum, calcite, pyrophyllite, quartz, clay, sandstone, bauxite and other processing industry related to metal and nonmetal mineDepending on the abrasiveness of the material to be ground and areas to be protected, different wear materials are used on our vertical roller mills The grinding elements are primarily made of alloy cast iron as per DIN 1695, hardfaced cast iron or composite materials with high Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS millsGKLM vertical grinding mill is one advanced powder making mill through our engineer re and experience It is ideal equipment for superfine milling industry which integrated with crushing, drying, grinding and collecting It is widely used in cement, power, metallurgy, chemical, nonmetallic mineralsVertical Grinding Mill, Vertical Roller Mill Powder

cement grinding roller mill price coal vertical mill

Vertical Roller Mills We have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials It is increasingly used as a solution for efficient grinding cement vertical Verical Roller Mill Vertical roller mill is MCC company to solve the industrial mill production is low, high energy consumption, technical difficulties, the European advanced technology absorption and mill design combined with the company for many years the concept of advanced manufacturing and market demand, after a hard grinding at large improvements in equipment designVertical Roller Mill,Verical Roller Mill Types RMs have become the grinding circuit of choice in cement plants for raw meal, clinker and coal grinding due to their lower capital cost and energy consumption compared to ball mills Loesche GmbH, Germany, has been a leading supplier of roller mills for over 100 years and in more recent times, has expanded by adding a subsidiaryFOR VERTICAL ROLLER MILLS Loesche

Vertical raw mill pradeep kumar SlideShare

Power taken by the millThe power taken up by the vertical roller mill is givenby the following expressionN =( I µ KT DR WDm πn ) / 60 K WWhere ,I = noof rollersµ = friction factor (007014 for raw materials , 00901 for coal)ΚT = specific roller pressure , kN/m2(400 – 800 for raw and coal)DR = roller diameter , mW = roller Vertical roller mill can replace ball mills or tube mills used for preparing coal Today VRMs with capacities up to 50 tph are the dominant technology for coal grinding Grinding media wear in a VRM will only be 5 to 10 g/ton of coal powder, as compared to 100 g/ton of coal powder in a ball mill Packaging Delivery: Packaging Details China Straight Centrifugal Grinder/Vertical Coal Roller HLM Vertical Roller Mill HLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology It features in a combination of drying grinding classifying and conveying HLM vertical grinding mill has high grinding efficiency low power consumption large feed size product fineness easy adjustment vertical roller mills for cement coal grinding

used vertical roller mills for coal grinding

vertical roller mills for coal grinding Vertical roller mills (VRM) can replace ball mills or tube mills used for preparing coal Today VRMs with capacities up to 50 tph are the dominant technology for coal grinding According to MIIT, grinding media wear in a VRM will only be 5 to 10 g/ton of coal powder, as compared to 100 g/ton of coal The coal vertical roller mill has less dust, low noise, high efficiency granular composition, and excellent combustion performance due to its special design and structure Chaeng(Great wall machinery) Vertical Roller Mill has simple process, compact structure, product fineness of 80μmR 3%, with steady and average product finenessVertical Coal Mill CHAENG Great Wall Machinery Within the power industry, vertical roller mills (VRMs) are the predominant equipment used for coal pulverisation The essential requirements of pulverisation are grinding, heating, classification and transport of the pulverised coal from the pulveriserCoal pulverisation with vertical roller mills Engineer Live

HLM Vertical Roller Mill Grinding Mills, Ultrafine

HLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology It features in a combination of drying, grinding, classifying and conveying HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process The roller of the vertical grinding mill is placed on the grinding table like a car wheel and is connected to a rocker arm When the vertical grinding mill is running, the position of the grinding roller is unchanged Grinding rollers do autobiographical movement without direct contact with the grinding tableVertical Roller Mill Manufacturers Provide High A compact coal mill solution for grinding virtually any type of raw coal Our ATOX® Coal Mill is a compact vertical roller mill that can grind almost any type of raw coal The coal mill utilises compression and shear force generated between the large rollers and the rotating table to crush and grind raw coal, removing the need for a separate Longlasting coal mill for efficient grinding

Grinding process within vertical roller mills:

Industry and Mine Automation, 2003(5): 213 (In Chinese) Fig 3 Sizing curves of actual and simulated products 5 Conclusions 1) Experimental results show that the coal grinding process consumes less energy in vertical roller mills than in ball mills: it is very important to select the proper equipment to be used in the grinding process Power taken by the millThe power taken up by the vertical roller mill is givenby the following expressionN =( I µ KT DR WDm πn ) / 60 K WWhere ,I = noof rollersµ = friction factor (007014 for raw materials , 00901 for coal)ΚT = specific roller pressure , kN/m2(400 – 800 for raw and coal)DR = roller diameter , mW = roller Vertical raw mill pradeep kumar SlideShare