Sendary Crusher Feed

2019-01-30T11:01:38+00:00

Secondary Crushing Equipment 911 Metallurgist

The simplest form of secondary crushing stage involves a single crusher, taking its feed by gravity flow direct from the primary with no interposed scalping separation This is tantamount to making the overall reduction in one machine, except Unless stated otherwise, standard settings were: % +1 inch in secondary crusher feed = 836, secondary crusher close side set = 316 cm, secondary screen opening = 143 cm, tertiary crusher close side set = 788 cm and secondary crusher Secondary Crushing Simulation 911 Metallurgist Cone crushers are fed with prescreened material from the primary crusher (usually a jaw crusher or primary gyratory), and the secondary crusher should always, if possible, have a scalped feed Ideally, the deck on the scalping screen should have a cut point equal to Perfecting the Performance of Secondary Crushers E

Secondary Impact Crushers MEKA Crushing

One of these designs is the MSI series secondary impact Crusher with two independent breaking plates, which may be adjusted by hydraulic setting rods Their large feed opening is a key advantage for most applications requiring the feeding of materials up When possible, the secondary crusher should be operated with a flooded crushing chamber, commonly referred to as ‘choke feeding the crusher’ In a top Maximising productivity from secondary cone crushers Secondary crushing of the SAG mill feed is undertaken to increase SAG mill power efficiency, thus allowing higher throughput in existing circuits Its application is best retro fitted to Brownfield operations where the benefit gained for capital expended is excellent The implementation of partial and total secondary crushing increasesSHEDDING LIGHT ON SECONDARY CRUSHING B Putland,

Effective feed control for a crusher VEGA

Effective feed control for a crusher Application In a quarry, the feed hopper above the secondary crusher is at the heart of the screening and grading process and this is a critical control point This is where the majority of aggregate comes through, it is a very noisy and dusty environment, with unpredictable flow patterns and material Secondary crushers are comparatively lighter in weight and smaller in size They generally operate with dry clean feed devoid of harmful elements like metal splinters, wood, clay, etc separated during primary crushing The common secondary crushers are cone, roll, and impact typesCrusher an overview ScienceDirect Topics When stone is processed in mobile primary crushing plants, excavators or wheel loaders feed the rock into the crusher that is set up at the quarry face, gravel pit or in a recycling yard or demolition site The crushed material is then either sent to the secondary/tertiary processing stage via stacking conveyors or transported by trucksPQ University Lesson 7 Crushing Secondary

Crusher level measurement and feed control VEGA

To achieve this, the ore is crushed to the correct size in two stages, in a primary and then a secondary crusher In order to enable an optimum throughput, and avoid choking or damaging the crusher, a reliable level measurement is required achieve a secondary crush feed These include: • Open circuit, no screening 100% of feed direct to – secondary crushing • Open circuit, with scalping screen Scalping of feed ahead – of the secondary crusher to remove fines • Open circuit, with intermediate crushing Primary crushed –SHEDDING LIGHT ON SECONDARY CRUSHING B Putland, A secondary cone crusher achieves its best work when fines smaller than the desired crusher product are removed from the feed When a crusher is operating with a full chamber, the nominal top size of the crusher discharge is approximately 16 times the Closed Side Setting (CSS) of a top performing secondary cone crusherMaximising productivity from secondary cone crushers

Crusher level measurement and feed control VEGA

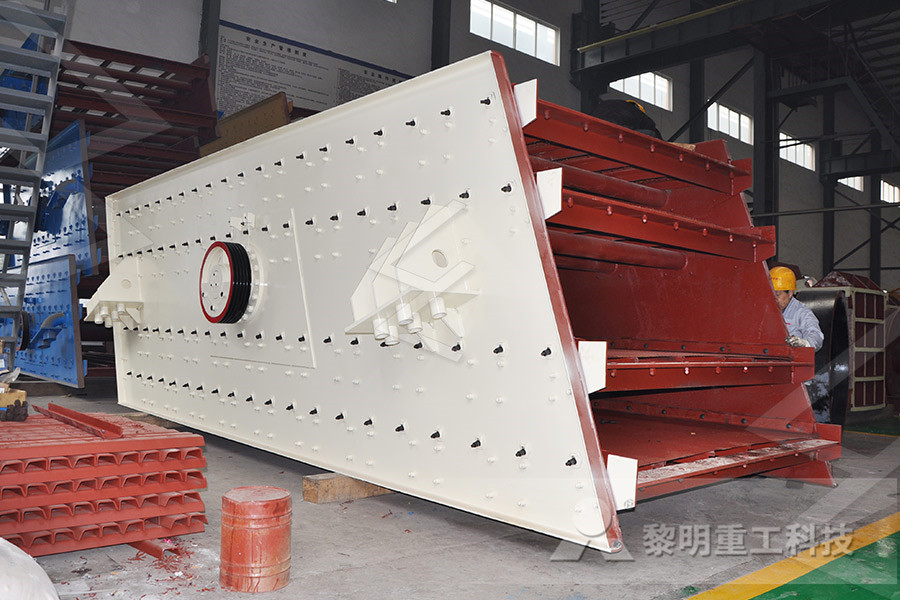

To achieve this, the ore is crushed to the correct size in two stages, in a primary and then a secondary crusher In order to enable an optimum throughput, and avoid choking or damaging the crusher, a reliable level measurement is required This flow concept keeps a choke feed to the crusher, eliminating stops/starts of the feed system, which improves production, material shape and wear Users are focused on cost, the environment, availability, versatility and, above all, the quality of the end product Simple crushing is a relatively easy processPQ University Lesson 7 Crushing Secondary The secondary crusher housing is a rugged, fabricated steel plate construction with heavy external bracing for increased strength and stability For quick and easy inspection of the internal wear parts, the housing is fitted with large doors which are opened and secured by a special mechanismSecondary Impactor HSI

Crushers an overview ScienceDirect Topics

The primary crusher converts the feed size to be acceptable to the secondary crusher 931 Coal Jaw Crusher This is used for crushing and breaking large coal in the first step of coal crushing plant applied most widely in coal crushing industryMcLanahan DDCSizers are direct drive crushersizers that are used in the primary and secondary reduction of friable, lowsilica minerals Used in both surface and underground mining operations, our Sizers can reduce materials such as coal, salt, gypsum, phosphate, limestone, bauxite, petroleum coke, lignite, trona, carbon anodes, oil sands, clay, shale and similar friable minerals The direct Primary Secondary DDCSizers McLanahanThe primary crusher is a CJ409, the secondary crusher is a CH430 and the screening is handled by an SK1854Sandvik A1552 has a max feed capacity of 155 mtph A1552 Crushing and screening plant — SRP

Blog: Three reasons why your primary crusher feed

The primary crusher is an important part of the mining process, taking the run of mine (ROM) ore and reducing it to a size which can be processed by the downstream operationsPRIMARY CRUSHERS; DJ 2418: DJ 3220: DJ 3224: DJ 3424: DJ 3628: DJ 4030: DJ 4232: DJ 4632: DJ 5234: DJ 6240: Feed Opening: Inches: 24×18: 32×20: 32×24: 34×24: 36 DJ Series Jaw Crusher Diamond Crusher achieve a secondary crush feed These include: • Open circuit, no screening 100% of feed direct to – secondary crushing • Open circuit, with scalping screen Scalping of feed ahead – of the secondary crusher to remove fines • Open circuit, with intermediate crushing Primary crushed –SHEDDING LIGHT ON SECONDARY CRUSHING B Putland,

SECONDARY IMPACT CRUSHER Apollo

of productivity reliability They are employed for secondary crushing with feed size from 150 to 300 mm and capacities from 10 to 800 TPH The first apron is adjustable by means of threaded spindles and elastically clamped by means of rubber buffer This prevents an excessive variation of the setting during the crusher’s operation The Diverting primary crushed ore to a surge bin ahead of a secondary crusher, and allowing the bin to overflow into a bypass achieved this INTRODUCTION In Australia, there are several examples of the retrofitting of secondary crushing circuits to reduce feed size and hence increase SAG mill capacity, most notably those of Kidston Gold MineTaking Control of the Mill Feed R2 Orway This flow concept keeps a choke feed to the crusher, eliminating stops/starts of the feed system, which improves production, material shape and wear Users are focused on cost, the environment, availability, versatility and, above all, the quality of the end product Simple crushing is a relatively easy processPQ University Lesson 7 Crushing Secondary

Crusher level measurement and feed control VEGA

To achieve this, the ore is crushed to the correct size in two stages, in a primary and then a secondary crusher In order to enable an optimum throughput, and avoid choking or damaging the crusher, a reliable level measurement is requiredThe primary crusher converts the feed size to one that is acceptable to the secondary crusher primary crusher for secondary azdocnl Secondary crusher Tertiary crusher Primary crusher has the ability to receive the crushing material a material that has to be crushed directly from the source i e quarry thats why these types of crusher are primary crusher secondary Continuous crusher feed thanks to CFS (Continuous Feed System) Crusher unit with innovative Cshape rotor ledges for top product quality Simple and intuitive control concept SPECTIVE Highperformance secondary screening unit with extralarge screening surface 3 4 Efficient and powerful diesel directdrive 5 7 6 2 1 MOBIREX MR 110 Z MR 130 Z EVO2MOBIREX MR 110 Z MR 130 Z EVO2

Size Reduction Equipment BIT Mesra

A primary crusher operates on run of mine material accepting anything that comes from the mine face and breaking into 150250 mm (610 in) A Secondary crusher reduces these lumps into 6 mm (1/4 in) Grinders reduce crushed feed to powders The product from a Still using the 32 x 54 Jaw Crusher example, the top size of the feed entering the crushing chamber has to follow the F80 rule that 80% of the top size feed material is smaller than the gape opening Using the F80 rule with the 32 x 54 Jaw Crusher, the 32” gape opening equals a 26” top sized feed, and with the 6:1 ratio of reduction, the Jaw Crushers McLanahan The primary crusher is an important part of the mining process, taking the run of mine (ROM) ore and reducing it to a size which can be processed by the downstream operationsBlog: Three reasons why your primary crusher feed