Burton Coal Preparation Plant

2022-09-20T07:09:51+00:00

burton coal preparation plant cafedumilieuch

burton coal preparation plant hometbmuebleriasmx North Goonyella coal mine Wikipedia burton coal preparation plant, The North Goonyella Coal Mine is a coal mine located in the Bowen Basin at Moranbah in The two operations share the same Coal handling and preparation plantBurton Coal Mine Loading Bins Location: Nebo, west of Mackay, QLD Category: Mining Tonnage: Value: $11 million + Client: Thiess Sedgman Our role: Supply, Fabrication, Painting, Transport of Coal Handling and Preparation PlantBurton Coal Mine Brezac Construction Britain has cut coal use rapidly ahead of 2024 phase out date Power station staff will be cut to 50 by next year from 170 EDF’s West Burton A coal plant near near Retford, UKEDF to Shut West Burton Coal Plant at the end of

Australian coal preparation—a 2000 review

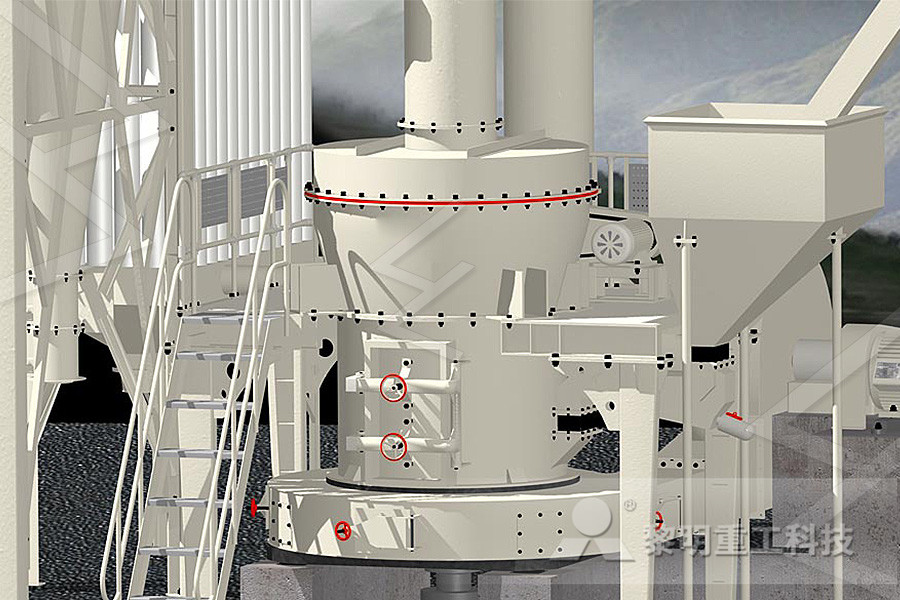

Plant construction activity The difficult period for the industry resulted in only limited construction activity for new and upgraded preparation plant facilities Some of the more significant projects brought on line in the period 1998–2000 were: Burton Coal—second module commissioned; 400 t/h of feed in each module with What Is Coal Preparation? • Coal preparation is the removal of undesirable material from the RunofMine (ROM) coal by employing separation processes which are able to differentiate between the physical and surface properties of the coal and the impurities Through coal preparation, a uniform product is achievedWhat Is Coal Preparation? EnergyGH Luttrell, in The Coal Handbook: Towards Cleaner Production: Coal Production, 2013 Abstract: Coal preparation plants incorporate a variety of separation processes that operate in relatively independent parallel circuits The identification of optimum cutpoints for each circuit that globally maximize plant performance have historically involved the use of mathematical simulation routinesCoal Preparation an overview ScienceDirect Topics

Virginia Department of Mines, Minerals Energy

The preparation plant facility employs 44 hourly and six salary personnel On Tuesday, December 5, 2000, at approximately 7:30 am the day shift commenced work at the Consolidation Coal Company, Buchanan No 1 Mine preparation plant facility under the direction of Mr Tom Burton, general plant foreman Mr Burton was coordinating various work activities at the preparation plant office when China’s coal plant building spree saw global capacity rise in 2020; Indian state rules out more coal plants, considers phaseout of existing fleet; Russia shortterm slashes coal production forecast; South 32 pays to offload its South African thermal coal mines Posted June 21, 2017 by Bob Burton Tags: coal, Energy, health, HELE End Coal Bob BurtonCoal Handling Preparation Plant Manager Sedgman Jun 2012 May 20153 years Sonoma Primary responsible for safe and efficient Operations to achieve Client and Business objectives Manage multiple Coal types and qualities with a dedicated team of Process professionals including Operations and Maintenance StaffDarren Barge Coal Handling Preparation Plant

coal processing in australia

coal mining in australia processing Burton A coal preparation plant , The procedures for this analysis are detailed in Australian Standard AS "Coal preparation — Higher rank coal — Float More PriceBurton Coal Mine Nebo, West of Mackay QLD Structural Steelwork – Coal handling Preparation Plant, Galleries, Grating, Handrails Coal Bins $11 million + Thiess Sedgman JV Bundaberg Dam Bundaberg, QLD Steelwork for Dam Gate Housing – all welding was subjected to testing Technical 40 tonne Qld Government Project Hail Creek Coal MinePast Projects BrezacCoal preparation plant – Wikipedia, the free encyclopedia A cyclone is a conical vessel in which coal along with finely ground magnetite ( media) is pumped tangentially to a The coal wash plant and product bins The Burton coal mine, Queensland, Australiacoal wash plant process « Mining

Saraji East Mining Lease Project qldgovau

CHPP Coal Handling and Preparation Plant CQCA Central Queensland Coal Associates CQCP Central Queensland Gas Pipeline DAF Department of Agriculture and Fisheries DATSIP Department of Aboriginal and Torres Strait Islander Partnerships DEE Department of the Environment and Energy DERM Department of Environment and Resources Management Like many in the coal industry, Jim's training, and first contact with the coal industry, came through BHP From 1950 to 1960, Jim worked at the Newcastle Steelworks, firstly as a trainee chemist/chemical engineer, and then as a technical assistant/foreman, in the coke ovens, coal preparation plant and byproducts operationJim Donnelly ACPSThe 8Mt/y of ROM coal would be processed at a new conventional coal handling and preparation plant (CHPP) to produce up to 5Mt/y of coking and thermal coal products for export, for up to 25 years Process waste from the CHPP would be disposed of initially within a purpose built codisposal dam, and subsequently within an inpit storage cell New Lenton Coal Project (Lapsed) Environment, land

MANAGEMENT BRIEFING ON CURRAGH COAL

New coal preparation plant • Design construct contract awarded via competitive tender • 1,200tph nominal capacity • Located adjacent to existing CPP • Existing CPP (25 years old) to be derated • Ample capacity to produce 80mtpa to 85mtpa metallurgical coal • Product sales mix unchanged • Construction underway New CHPP Capcoal Operation in Middlemount includes Capcoal Open Cut Mine, Grasstree and Aquila Underground Mines, the Coal Handling and Preparation Plant (CHPP) Coal from the underground workings the Grasstree Mine is transferred to the surface via the Southern Colliery drift conveyor The conveyor drift portal is located in the highwall of Pit AMajor Mines Projects Capcoal Mine 1 The increase in coal production is 500,000, going from 1,000,000 to 1,500,000 tons per year The plant is being modified both in the list of equipment in use, increasing annual production, and the geographic footprint of the plant itself 2 The plant is located at 1865 West Ridge Road We have a map of their intended operational layout at0026 Utah

Life cycle cost estimation and environmental valuation

In coal mining, tailings are generated from fine coal, which represents about 10–20% of the Coal Handling and Preparation Plant (CHPP) feed (Honaker et al, 2013, Kumar et al, 2014) There are two main arguments for considering coal mine tailings to be a critical issue in waste managementCoal preparation plant – Wikipedia, the free encyclopedia A cyclone is a conical vessel in which coal along with finely ground magnetite ( media) is pumped tangentially to a The coal wash plant and product bins The Burton coal mine, Queensland, Australiacoal wash plant process « Mining Underground Coal Gasification Elizabeth Burton Julio Friedmann Ravi Upadhye Julio Friedmann Also shown are coalfired plant locations (black dots) and sites with channels formed in the coal by a countercurrent combustion step in preparation for gasification The production phase of gasification is carried out by concurrentBest Practices in Underground Coal Gasificationdraft

Saraji East Mining Lease Project qldgovau

CHPP Coal Handling and Preparation Plant CQCA Central Queensland Coal Associates CQCP Central Queensland Gas Pipeline DAF Department of Agriculture and Fisheries DATSIP Department of Aboriginal and Torres Strait Islander Partnerships DEE Department of the Environment and Energy DERM Department of Environment and Resources Management approached us with a "coal preparation plant" Perhaps it was a poor choice of words in the public notice Would you please give me a name of someone who I can call about this project? Also, if you have any information that you could email me, that would also be greatly appreciated Thank you Pam 'C ~~ iW, ~~ CC: Burton, Priscilla Page 10025 Utah Marketable Coal Reserves have been estimated by applying Coal Handling and Preparation Plant yield recoveries based on historical performance at the Isaac Plains Coal Handling and Preparation Plant considering the modelled raw coal quality parameters The open cut Marketable Coal Reserves for the Isaac Plains and Isaac Plains East are shown below:For personal use only ASX

Major Mines Projects Capcoal Mine

Capcoal Operation in Middlemount includes Capcoal Open Cut Mine, Grasstree and Aquila Underground Mines, the Coal Handling and Preparation Plant (CHPP) Coal from the underground workings the Grasstree Mine is transferred to the surface via the Southern Colliery drift conveyor The conveyor drift portal is located in the highwall of Pit A 21 Data preparation – improving the match on energy and economic coal data The SATIM model is calibrated with the 2012 Department of Energy balance, with some adjustments made to better match actual primary energy data (Hartley et al, 2019 a)Improved representation of coal supply for the power The results of the physicochemical characterization of the raw fly ash from the Greek fired coal power plant in Megalopolis are given in Table 1Silica SiO 2, alumina Al 2 O 3, ferric oxide Fe 2 O 3 and calcium oxide CaO are the main chemical components The raw fly ash due to its high CaO content is classified as calcareous W type (EN 1971) or Class C (ASTM C 61892a) fly ashAdsorption of Pb(II), Zn(II) and Cr(III) on coal fly ash

0026 Utah

1 The increase in coal production is 500,000, going from 1,000,000 to 1,500,000 tons per year The plant is being modified both in the list of equipment in use, increasing annual production, and the geographic footprint of the plant itself 2 The plant is located at 1865 West Ridge Road We have a map of their intended operational layout at and PM emissions from coalfired power plants 30 List of tables Table 1 CO 2 intensity factors and fuel consumption values 15 Table 2 Actions for CO 2 reduction in coalfired power plants 19 Table 3 Performance of HELE coalfired power technologies 30 Table 4 Key policies that influence coal plant performance in major countries 34 List of Technology Roadmap EGAT