cement ball milling of raw materials

2020-05-05T16:05:23+00:00

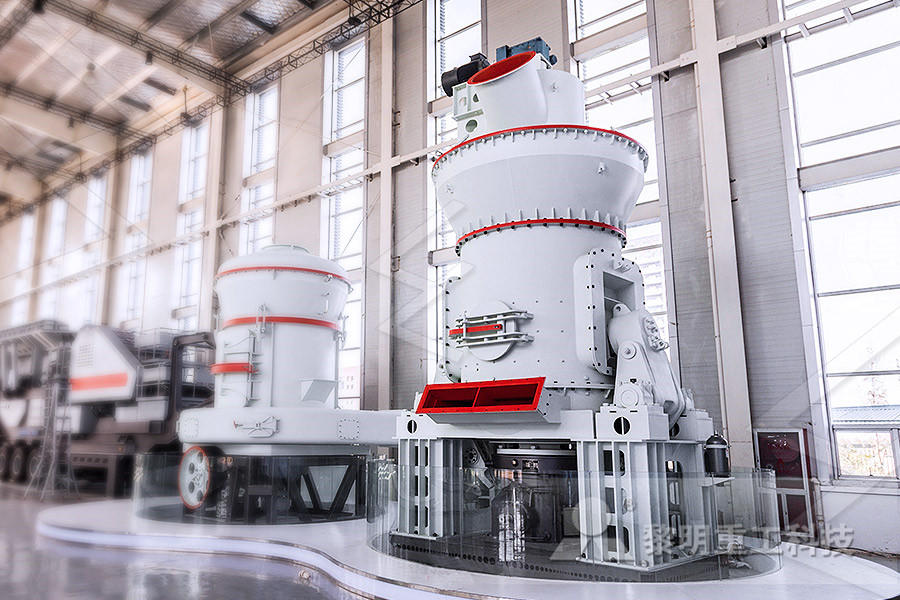

Raw Material Ball Mill

Overview This ball mill is mainly used for grinding raw materials and final products in cement plant It can be replaced by vertical raw mill It is also suitable for grinding various ores and other materials in the metallurgy, mine, chemical, construction and other industriesBall Milling Raw Materials cement ball milling of raw materials Cement Mill Grinding Balls Materials Accinsacoza he ball mill for clinker is an efficient tool for fine powder grinding It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy chemical electric power and other industries ball mill for cement milling clinker raw maetrial deipacement miller, cement milling machine, cement raw material ball mill US $$ / Set 1 Set (Min Order) 9 YRS Zhengzhou Huanqiu Heavy Industries Ltd 1000% Contact Supplier Compare 2Has over 60 years history 3Main body wholelife warranty Ball mill is an efficient tool for grinding many materials into fine powder The Ball raw material milling cement netwerkoostkampbe

Ball Milling Of Raw Materialsball Mill

Ball Milling Raw Materials Ftmlie Heavy Machinery Raw material ball mill it can be replaced by vertical raw mill it is also suitable for grinding various ores and other materials in the metallurgy mine chemical construction and other industries besides the raw mill has two forms of milling one is an open form and the other is a recycle close Raw mill is also called cement raw mill, similar to cement ball mill, it is an important cement milling equipment used in the cement production process Raw mill is mainly used for grinding cement raw meal in the cement factory production process It is also suitable for metallurgical, chemical, electric power and other industrial mining enterprises to grind various ores and other grindable Cement Raw Mill in Cement Plant for Ball Mill for Ball milling raw materials A raw mill is the equipment used to grind raw materials into rawmix during the manufacture of cement rawmix is then fed to a ce The mixed raw materials cement raw meal before cement production and the finished produc Ball Milling Raw Materials pomocdrogowabychawapl

Scaledup production of alkaliactivated cement in the

Ballmills are commonly used in Portland cement production, noting that hightemperature processing (in a rotary kiln) is the primary step in transforming the raw materials into Portland cement (clinker) Ballmilling is used in the process for size reduction to raise the specific surface area of Portland cement for more thorough and timely The quality of cement clinker is directly related to the chemistry of the raw materials used Around 80–90% of raw material for the kiln feed is limestone Clayey raw material accounts for between 10–15%, although the precise amounts will vary Magnesium carbonate, which may be present in limestone, is the main undesirable impurity The levelCEMENT RAW MATERIALS CemNet Transformation of raw materials into hydraulic cement, and the change in crystalline structure caused by ballmilling support the mechanochemical effects rendered by this milling process 23 Characterization methods The hydraulic cement was used to prepare mortar mixturesOnepart alkali activated cement based volcanic

Cement Finish Milling (Part 1: Introduction amp;

Introduction Cement is manufactured by heating a mixture of ground limestone and other minerals containing silica, alumina, and iron up to around 1450 C Raw Material Preparation Cement Plants and Kilns in From the early 1900s, both for cement grinding and for grinding hard raw materials, whether by wet or dry process, the standard arrangement was a ball mill for preliminary grinding (to below 075 mm), followed by a tube mill for fine grindingcement raw material ball mill schindlers Raw Material Ball MillThis ball mill is mainly used for grinding raw materials and final products in cement plant It is also suitable for grinding various ores and other materials in the metallurgy, mine, chemical, construction and other industries Besides, the raw mill has two forms of millingBall Mill

Cement Raw Mill in Cement Plant for Ball Mill for

Raw mill is also called cement raw mill, similar to cement ball mill, it is an important cement milling equipment used in the cement production process Raw mill is mainly used for grinding cement raw meal in the cement factory production process It is also suitable for metallurgical, chemical, electric power and other industrial mining enterprises to grind various ores and other grindable raw ball mill raw mill machine cement raw mill chemical and construction Besides, it has two forms of milling, one is an open form, and the other is a recycle close form equipped with powder concentrator It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical raw ball mill raw mill machine cement raw millCement milling is usually carried out using ball mills with two or more separate chambers containing different sizes of grinding media (steel balls) Grinding clinker requires a lot of energy How easy a particular clinker is to grind ("grindability") is not always easy to predict, but large clusters of belite due to coarse silica in the feed Cement Milling Understanding Cement

ball mill for cement milling clinker raw maetrial deipa

Ball Milling Raw Materials cement ball milling of raw materials Cement Mill Grinding Balls Materials Accinsacoza he ball mill for clinker is an efficient tool for fine powder grinding It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy chemical electric power and other industries Ballmills are commonly used in Portland cement production, noting that hightemperature processing (in a rotary kiln) is the primary step in transforming the raw materials into Portland cement (clinker) Ballmilling is used in the process for size reduction to raise the specific surface area of Portland cement for more thorough and timely Scaledup production of alkaliactivated cement in the Transformation of raw materials into hydraulic cement, and the change in crystalline structure caused by ballmilling support the mechanochemical effects rendered by this milling process 23 Characterization methods The hydraulic cement was used to prepare mortar mixturesOnepart alkali activated cement based volcanic

raw material mill process cement netwerkoostkampbe

The cement quality control of cement plant is mainly based on specific technological process, which includes the quality control of various raw materials, semifinished products used in the production process, the sampling analysis of materials, to ensure the stability and uniformity of raw 1,233 raw materials cement industry products are offered for sale by suppliers on Alibaba, of which refractory accounts for 2%, electronics chemicals accounts for 1%, and cement making machinery accounts for 1% A wide variety of raw materials cement industry options are raw materials cement industry, raw materials cement Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant The cement ball mill usually can be applied to raw meal grinding or cement grinding Besides, the cement ball mill also can be used for metallurgical, chemical, electric power, other mining powder grinding, and other grindable materialsball mill operation in cement raw material grinding

Raw Material Ball Mill

Overview This ball mill is mainly used for grinding raw materials and final products in cement plant It can be replaced by vertical raw mill It is also suitable for grinding various ores and other materials in the metallurgy, mine, chemical, construction and other industriesCement Raw Material Ball Mill In South Africa 116 portland cement manufacturing 1161 process description17 portland cement is a fine powder gray or white in color that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates aluminates and aluminoferrCement Raw Material Ball Mill In South Africa Dry ball mill directly transfers the materials to the mill, and crushes and grinds the raw materials by the impact of the steel ball through the rotation of the mill It is mainly used to crush and grind some materials that will react with water, such as cement and marbleWhat is the ball milling process? Crushers, Sand

Ball Milling Of Raw Materialsball Mill

Ball Milling Raw Materials Ftmlie Heavy Machinery Raw material ball mill it can be replaced by vertical raw mill it is also suitable for grinding various ores and other materials in the metallurgy mine chemical construction and other industries besides the raw mill has two forms of milling one is an open form and the other is a recycle close Cement milling is usually carried out using ball mills with two or more separate chambers containing different sizes of grinding media (steel balls) Grinding clinker requires a lot of energy How easy a particular clinker is to grind ("grindability") is not always easy to predict, but large clusters of belite due to coarse silica in the feed Cement Milling Understanding CementBall milling raw materials overview this ball mill is mainly used for grinding raw materials and final products in cement plant it can be replaced by v Ball Mill Raw Materials PANOLA Mining machine Ball Mill Raw Materials This table of ball mill bond work index of minerals is a summary as tested on around the world sample you can find the Ball Milling Raw Materials pomocdrogowabychawapl

raw material mill process cement netwerkoostkampbe

The cement quality control of cement plant is mainly based on specific technological process, which includes the quality control of various raw materials, semifinished products used in the production process, the sampling analysis of materials, to ensure the stability and uniformity of raw raw materials with sand and vertical mills in Tanzania Cement grinding Vertical roller mills versus ball mills grinding of raw materials The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system However, despite these benefits, applications ofraw material for ball mill tanzania Introduction Cement is manufactured by heating a mixture of ground limestone and other minerals containing silica, alumina, and iron up to around 1450 C Cement Finish Milling (Part 1: Introduction amp;