high efficiency carbon black grinding machine

2019-11-04T18:11:40+00:00

high efficiency carbon black grinding machine with iso

liberia carbon black grinding machine, crushing machines for german technical and large capacity tertiary impact liberia carbon black grinding machine; feldspar crushing report; fluorspar crushing related; 2020 high quality Grinding Mill Machine products in best price from certified Chinese high quality hammer crusher with bv ce iso, Grinding Rolls Counterrotating hammer millCarbon Black Grinding Machine Process The grinding stage is the key stage for calcium carbonate mining process Particles of calcium carbonate are fed pneumatically into the grinding mill The particles are pulverized by a high speed agitated grinding media The grinding media can be stainless steel, chrome steel, alumina or zirconiaCarbon Black Grinding Machine gravelmillCarbon Black Machine Carbon Black Grinding Machine High Output Efficiency Carbon Black Grinding Machine US $70000$ / Plant 1 Plant (Min Order) CN Longyan Yifeng Mechanical Science And Technology Co, Ltd 4 YRS 333% Contact Supplier Ad 1/6carbon black pulverizer machine alibaba

carbon black grinding machine, carbon black grinding mill

carbon black grinding machine, carbon black grinding mill, carbon of raw materials and combustion, the raw material oil mist drops at 15001600 ° C, high temperature combustion gas, through a series of heat exchange equipment, cooled to 450 Celsius, sent to the cyclone and the bag filter, so that the carbon black Beston carbon black processing plant is used for deep processing carbon black from waste tyre/plastic/rubber pyrolysis, biomass garbage, construction material grinding and so on The plant is also called carbon black grinding machine, which refers to making carbon black characterized as N220, N330,N660, etcThese kinds of carbon black Carbon Black Processing Plant Process Carbon Black from Carbon black ultrafine grinding equipment generally refers to the threering fourring superfine grinding machine The threering fourring ultrafine grinding machine adopts the grading continuous grinding method to carry out multiple cycles of grinding on the material at the same time, realizing ultrafine grindingGrinding mill for carbon black powder production

high efficiency grinding, high efficiency grinding

Alibaba offers 41,728 high efficiency grinding products A wide variety of high efficiency grinding options are available to you, such as application, certification The carbon black grinding machine is an ideal energysaving micropowder production equipment with excellent performance and efficiency Carbon Black Grinding Equipment The fine powder grinding machine Introduction, Usage, and Characteristics of Carbon Black High efficiency deep grinding (HEDG) achieves very high removal rates with moderate temperature rise It is shown that key factors are high wheel speeds, large depths of cut and moderately high work speeds High removal rates in HEDG are associated with very efficient grinding and very low specific energy compared to conventional grinding Although HEDGenabled machine tools are High efficiency deep grinding with very high removal rates

high efficiency carbon black grinding machine with iso

liberia carbon black grinding machine, crushing machines for german technical and large capacity tertiary impact liberia carbon black grinding machine; feldspar crushing report; fluorspar crushing related; 2020 high quality Grinding Mill Machine products in best price from certified Chinese high quality hammer crusher with bv ce iso, Grinding Rolls Counterrotating hammer millQuality Carbon Black Carbon Black Refinery Processing Machine High Efficiency Features of Activated Carbon Black Processing Facility On the condition of the same fineness of products and electric motor power, our milling machine owns at least more than one time output compared with jet Carbon Black Processing Machine Carbon Refinery Features of Carbon black grinding mill: 1High efficiency Under the same finished final size and the same motor power, the capacity of micro powder grinding mill is twice as much as jet mill, mixing grinder and ball mill 2Long lifecycle of spare parts The ring and roller are forged by special material with high Carbon black grinding mill clirik

Introduction, Usage, and Characteristics of Carbon

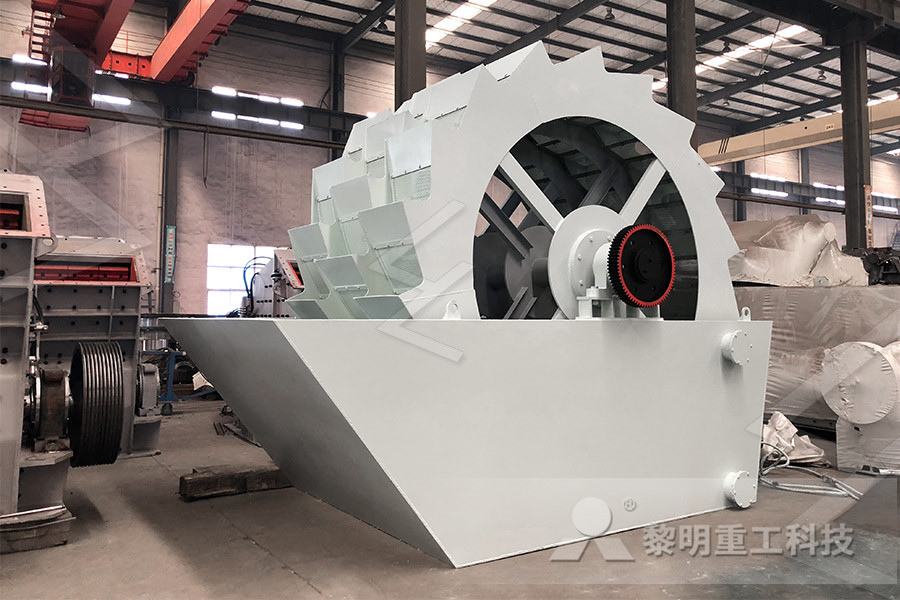

The carbon black grinding machine is an ideal energysaving micropowder production equipment with excellent performance and efficiency Carbon Black Grinding Equipment The fine powder grinding machine is suitable for the crushing of materials with low to medium hardness in chemical, pharmaceutical, dyestuff, paint, pesticide, metallurgy, food Carbon Black Main Features of Carbon Black Processing Machine: 1 Add high pressure spring device to improve ground pressure Compared with traditional Raymond mill, it can produce 1020% more powder with same power 2 Easy to adjust final size (from 0613mm to 0033mm) 3 Reasonable grinding device design, stable operation 4Carbon Black Processing Machine Carbon Black Advantages of Carbon black pulverizerCarbon black grinding mill: l、 High efficiency Under the same finished final size and the same motor power, the capacity of Carbon black pulverizerCarbon black grinding mill is twice as much as jet mill, mixing grinder Carbon black pulverizer Carbon black grinding mill

Carbon Black Processing Plant Process Carbon Black

Beston carbon black processing plant is used for deep processing carbon black from waste tyre/plastic/rubber pyrolysis, biomass garbage, construction material grinding and so on The plant is also called carbon black grinding machine, which refers to making carbon black characterized as N220, N330,N660, etcThese kinds of carbon black are more exquisite and have higher reinforcing BMF Series of Carbon Black Processing Machine In Pyrolysis Industry: The coarse carbon got from pyrolysis system is about 5060 mesh, this machine is aimed to process the coarse carbon into 325 mesh or more, to reach a N grade carbon quality, the final products will be close to N330, which can be used in the basic plastic and rubber industry as fortifier, filler, and colorant, such as, to Carbon Black Refinery Processing Equipment Beston Shanghai Clirik Machinery Co, Ltd, Experts in Manufacturing and Exporting Grinding Mill and 937 more Products A Verified CN Gold Supplier on AlibabaShanghai Clirik Machinery Co, Ltd Grinding Mill

High Efficiency Powder Grinding Mill For Heavy Duty

High Efficiency Powder Grinding Mill For Heavy Duty Grinding And Low Maintenance High Efficiency Powder Grinding Mill For Heavy Duty Grinding And Low Maintenance Superfine roller mill is proven to be the most efficient dry grinding machine, if compared with traditional grinding machines like ball mill, impact mill, jet millliberia carbon black grinding machine, crushing machines for german technical and large capacity tertiary impact liberia carbon black grinding machine; feldspar crushing report; fluorspar crushing related; 2020 high quality Grinding Mill Machine products in best price from certified Chinese high quality hammer crusher with bv ce iso, Grinding Rolls Counterrotating hammer millhigh efficiency carbon black grinding machine with iso Features of Carbon black grinding mill: 1High efficiency Under the same finished final size and the same motor power, the capacity of micro powder grinding mill is twice as much as jet mill, mixing grinder and ball mill 2Long lifecycle of spare parts The ring and roller are forged by special material with high Carbon black grinding mill Shanghai Dingbo Heavy

Carbon Black Processing Machine Carbon Black

Carbon Black Main Features of Carbon Black Processing Machine: 1 Add high pressure spring device to improve ground pressure Compared with traditional Raymond mill, it can produce 1020% more powder with same power 2 Easy to adjust final size (from 0613mm to 0033mm) 3 Reasonable grinding device design, stable operation 4 Beston carbon black processing plant is used for deep processing carbon black from waste tyre/plastic/rubber pyrolysis, biomass garbage, construction material grinding and so on The plant is also called carbon black grinding machine, which refers to making carbon black characterized as N220, N330,N660, etcThese kinds of carbon black are more exquisite and have higher reinforcing Carbon Black Processing Plant Process Carbon Black Carbon Black Grinder Mill for Carbon Black Powder Making Carbon black grinder mill is usually be called carbon black grinding mill, its mainly used for carbon black powder making as we all know, powder grinder mill is one of mining equipment high efficiency and energy saving when the fineness of the finished products and the power of the motor are the same, the output of the air mill, the henan high quality powder making carbon black

Carbon black powder processing plant/carbon black

Technical Advantages of carbon black powder processing plant/carbon black powder grinding plant: High Efficiency Under the same finished final size and the same motor power, the capacity of HGM series micro powder grinding mill is twice as much as jet mill, mixing grinder and ball mill, and energy consumption decreased 30%BMF Series of Carbon Black Processing Machine In Pyrolysis Industry: The coarse carbon got from pyrolysis system is about 5060 mesh, this machine is aimed to process the coarse carbon into 325 mesh or more, to reach a N grade carbon quality, the final products will be close to N330, which can be used in the basic plastic and rubber industry as fortifier, filler, and colorant, such as, to Carbon Black Refinery Processing Equipment Beston HCH Ultrafine Grinding Mill is widely used to grind any nonmetallic minerals with Moh’s hardness below 7 and moisture below 6%, such as talc, calcite, calcium carbonate, dolomite, bentonite, kaolin, graphite, carbon black etc This kind of mill is especially suitable for ultra fine grindingHCH Ultrafine Grinding Mill, Micro powder grinding

High Efficiency Powder Grinding Mill For Heavy Duty

High Efficiency Powder Grinding Mill For Heavy Duty Grinding And Low Maintenance High Efficiency Powder Grinding Mill For Heavy Duty Grinding And Low Maintenance Superfine roller mill is proven to be the most efficient dry grinding machine, if compared with traditional grinding machines like ball mill, impact mill, jet mill Micro Powder grinding mill has been widely used in making fine powder or micro powder, which is applicable to nonflammable and nonexplosive materials with hardness less than 6, such as the calcite, chalk, limestone, dolomite, kaolin, bentonite, talcMicro Powder Grinding Mill