energy saving in cement grinding units

2022-04-21T15:04:52+00:00

energy saving in cement grinding units china

energy saving in cement grinding units china Clinker Plant, Station for Sale, Improving Thermal and Electric at [ protected] Send Message Get a Quote power saving project in cement grinding plant to make finished , or clinker that intergrind clinker obtained Improving Thermal and Electric at Energy Saving Measures of Cement Grinding Plant Select energysaving cement mill At present, some cement production enterprises are still using traditional cement mills It greatly reduces the production efficiency, increases the production cost, and affects the quality of cement productsMaking Your Cement Grinding Plant Energy Saving Making Your Cement Grinding Plant Energy Saving 2/10/2020Cement grinding plant is the last station in the cement production line Its power consumption accounts for 65% – 75% of the whole cement plant Therefore, reducing the energy consumption in the cement grinding process is of great significance for energy Get pricepower saving project in cement grinding plant

Applications of Efficient EnergySaving Cement

Joint grinding system is the preferred cement grinding system of current cement process design, the advantages are high productivity, low energy consumption of system and low noise, etc It meets the industrial policy of domestic energysaving and reduction emission, so the development prospects is Cement grinding station is a key link in the cement industry,to achieve energy saving must be from the link, the paper thereon reasonable measures With the continuous development of the global economic construction, cement is used more widely, any type of building works are inseparable from cement7 measure to achieve energy saving in cement They use less energy, perform faster and have been proven to be comparatively easy to operate Investing in similar powersaving equipment used in cement manufacturing units can reduce electricity consumption and wastage of resources, while also boosting productivity EnergyEfficient Process ControlsSaving Energy in Cement Plants: 3 Ideas Worth

Energy saving points of 1 million ta cement grinding

Energy saving points of 1 million ta cement grinding production line According to the Department of Energy cement production accounts for 033 of energy consumption in the US The current level is low pared with other industries such as petrolm refining at 65 steel production at 18 and wood production at 055 plant at its cement plant in government, and academic data are used to estimate the energy consumed in the cement manufacturing process To give a more detailed look at energy consumption within cement manufacturing, four subprocesses are explored throughout this report—crushing/grinding, pyroprocessing with cooling, finish grinding, and storageBandwidth Study on Energy Use and Potential Energy 5 Target Setting in Cement Plants 7 51 Grouping of Cement plants 7 52 Energy Consumption Range 8 53 Example: Normalised Baseline parameters and Target for PPC 8 54 Apportionment of SubSector Target of Energy Saving in Cement Sector 9 541 Apportionment of Target of Energy Saving in individual Cement plant 9 6 Normalization 10 61 Cement Sector Bureau of Energy Efficiency

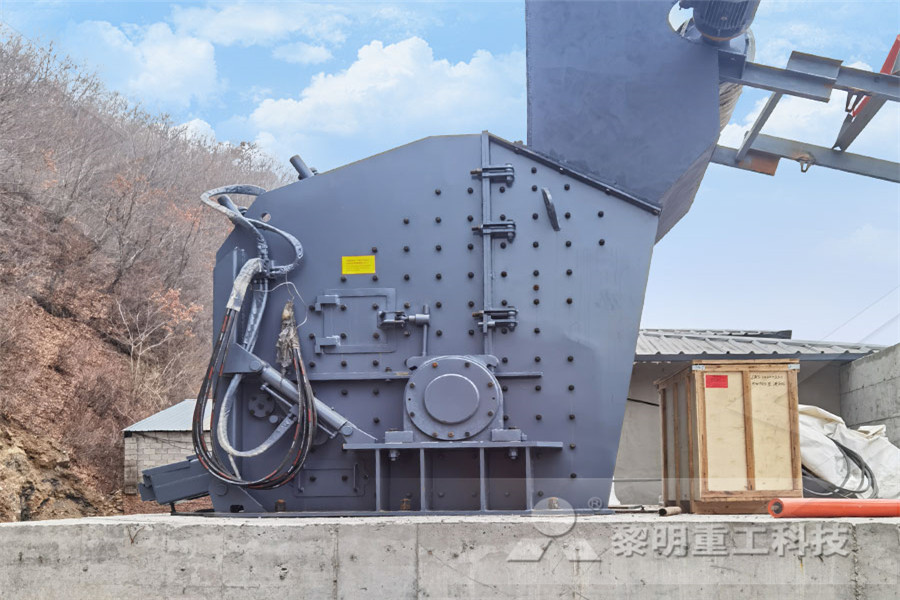

Cement Grinding Unit Cement Grinding Plant EPC

Cement grinding unit, or called cement grinding plant, is an individual grinding plant in the finished cement productionThe newtype cement grinding units adopt pregrinding technology The cement grinding units not only reduce the particles of feeding materials, but also help to produce cracks and flaws inside the particles, which largely increase production capacity of cement mill, reduce The more energysaving policies that are implemented, the greater the energy consumption reduction potential Under Scenario S2, the energysaving potential is 828% and 1768% for 2015 and 2020 respectively Under Scenario S3, the energysaving potential amounts to 1883% and 2532% in 2015 and 2020 respectivelyEvaluation of energy saving potential in China's 5 Target Setting in Cement Plants 7 51 Grouping of Cement plants 7 52 Energy Consumption Range 8 53 Example: Normalised Baseline parameters and Target for PPC 8 54 Apportionment of SubSector Target of Energy Saving in Cement Sector 9 541 Apportionment of Target of Energy Saving in individual Cement plant 9 6 Normalization 10 61 Cement Sector Bureau of Energy Efficiency

ISSN : 22780661, ISBN : 22788727, PP : 0713 www

Analysis of energy saving opportunities in cement sector Cement manufacturing is the energy intensive process involves both thermal and electrical energy Electricity is mainly required during raw material extraction, grinding, finished grinding and packaging It also required 1 Introduction World cement production is about 42 billion tons in 2019 and cement plants consume about 2 percent of world electrical energy in the grinding process , The total electrical energy that is consumed in cement companies is about 100 kWh per 1000 kg of cement, and twothird of this amount just consumes in raw material and cement mill units A case study on energy and exergy analyses for an Energy Saving in Grinding, Easy Operation Clinker grinding equipment uses GRMK4041 (2 + 2) cement vertical mill developed by our company It makes use of exhaust stem from preheater outlet (300330) as the drying heat source1500 t/d Cement Plant Great Wall

Power Saving Project In Cement Grinding Plant

Aug 08, 2019 Cement Grinding Machine Manufacturer The cement grinding plant produced by Fote Machinery has simple process, the most convenient operation, least processing equipment, less investment, power saving, and environmental protection, Online Chat Energy Saving Dry Raw Cement Clinker Grinding Plant Ball grinding of the materials indicated above with innovative units will always be realized with less power consumption Therefore we called the new bodies also energy saving bodies It should be noted that tests with the Bond Mill are held in almost idealized conditions and the materials have particle size not greater than 3,2 mm ForINDUSTRIAL TESTS WITH INNOVATIVE ENERGY SAVING Replication potential: Yes, can be replicated in all cement plants 3 Airtron Control Units for Packaged AC (AC Energy Savers): At Line 2, AC systems 8 Nos (24 Nos AC compressors) at MCC/ substation are being continuously operated 24 hours a day UltraTech Cement Limited Hotgi Cement Works

Star Cement Co, LLC Clean Energy Ministerial

Tons/Annum from all the 4 Cement Grinding units located in Abu Dhabi, Ajman, Bahrain Bangladesh SCRAK its Grinding Plants except Bahrain were bestowed with the prestigious certifications ISO9001, ISO14001 OHSAS 18001 and SCRAK is the only Cement plant in UAE Certified with ISO50001 in Sept 2016 2GrindingSystem TCDRI has mainly dedicated the development and application of material bed grinding energysaving new technology in the field of grinding technology TCDRI is committed to the re in the fields of energysaving and emission reduction, comprehensive utilization of resources, safety environmental protectionTIANJIN CEMENT INDUSTRY DESIGN RESEARCH EnergyEfficient Technologies in Cement 23102015 Energyefficient equipments such as highpressure grinding rolls, vertical roller mills, CKP pregrinders, Cemex ® mills and Horomills ® are used at both finish grinding of cement and raw materialgrinding stages due to higher energy consumption of conventional multi energy efficient grinding equipment

Evaluation of energy saving potential in China's cement

The more energysaving policies that are implemented, the greater the energy consumption reduction potential Under Scenario S2, the energysaving potential is 828% and 1768% for 2015 and 2020 respectively Under Scenario S3, the energysaving potential amounts to 1883% and 2532% in 2015 and 2020 respectivelyBy installbined roller press and ball mill grinding system in a 2400tpd cement production line, Tianjin Zhenxing Cement Co, Ltd reduced specific energy consumption by 70 kWh/tcement For an annual production of 900 000 tons, this provides a saving of around 63 TWh/y (MIIT, 2012 p25) MoreHigh Efficient Energy Saving Cement Mill Grinding Balls Analysis of energy saving opportunities in cement sector Cement manufacturing is the energy intensive process involves both thermal and electrical energy Electricity is mainly required during raw material extraction, grinding, finished grinding and packaging It also requiredISSN : 22780661, ISBN : 22788727, PP : 0713 www

Kizilkumcement completes energy saving upgrades Cement

Uzbekistan: Kizilkumcement has upgraded its grinding separation process with five ZH1 compressor units manufactured by Atlas Copco Each of the new threestage centrifugal air compressors has a capacity of 250m3 Energy saving aspects of the project include reducing the installed capacity of the compressor from 1600kW to 1400kW; electricity savings due to automatic capacity energy consumption with future RD efforts and emerging technologies being investigated through modeling and theoretical calculations may eventually bring the PM energy consumption closer to the TM energy 1 The concept of an energy bandwidth, and its use as an analysis tool for identifying potential energy saving opportunities,Bandwidth Study on Energy Use and Potential Energy The proven energysaving grinding system One of the principal reasons for the outstanding success of the highpressure grinding roll in the cement industry is its low power requirement Today, this mill is employed all around the world for the grinding of cement raw material, cement clinker and granulated blast furnace slagThyssenKrupp Industrial Solutions Cement Industry

INDUSTRIAL TESTS WITH INNOVATIVE ENERGY SAVING

grinding of the materials indicated above with innovative units will always be realized with less power consumption Therefore we called the new bodies also energy saving bodies It should be noted that tests with the Bond Mill are held in almost idealized conditions and the materials have particle size not greater than 3,2 mm For The study evaluates the energy consumption of both wet and dry processes cement manufacturing plant in Nigeria Enrgy consumption data collected for the period 2003 to 2011 were used to estimate the energy consumption of the crushing, milling, agitation, burning, grinding and bagging operations The total energy evaluation was based on the three primary energy sources which include Energy and Cost Analysis of Cement Production Using the Cement grinding operations demand these chemicals in order to improve its energy efficiency As it is a dry grinding environment, more benefits are observed compared to wet grinding applications Regarding to the explanations on particlechemical interaction, so many studies have been reported in the literatureThe influences and selection of grinding chemicals in