gold ore mining processing plant diagram

2021-06-06T06:06:19+00:00

Gold Processing Plant Flow Diagram

flow diagram for production gold – Beneficiation Plant For Iron gold production flow chart – Coal processing system Machine Find the Right and the Top gold production flow chart for your coal handling plant!, a mining Click Chat Nowgold mine equipment flow chart – Ore Mining bentonite wet processing plant pdf Chromite ore beneficiation plant turkey XZM Series You can expect various gold mine equipment flow chart Mobile gold mine equipment is made for flexible application in quarry and mine processinggold mining process flow chart pdf Mining A blockflow diagram of a typical CIP plant for a nonrefractory gold ore is shown in Figure 2 Table I and Table II illustrate the capital and operating cost breakdowns for a typical South African gold plant These figures are not a standard but reflect the nature of the ore and the design basis for a particular situationThe process design of gold leaching and carboninpulp

Diagram Of Gold Mining Processing Blogger

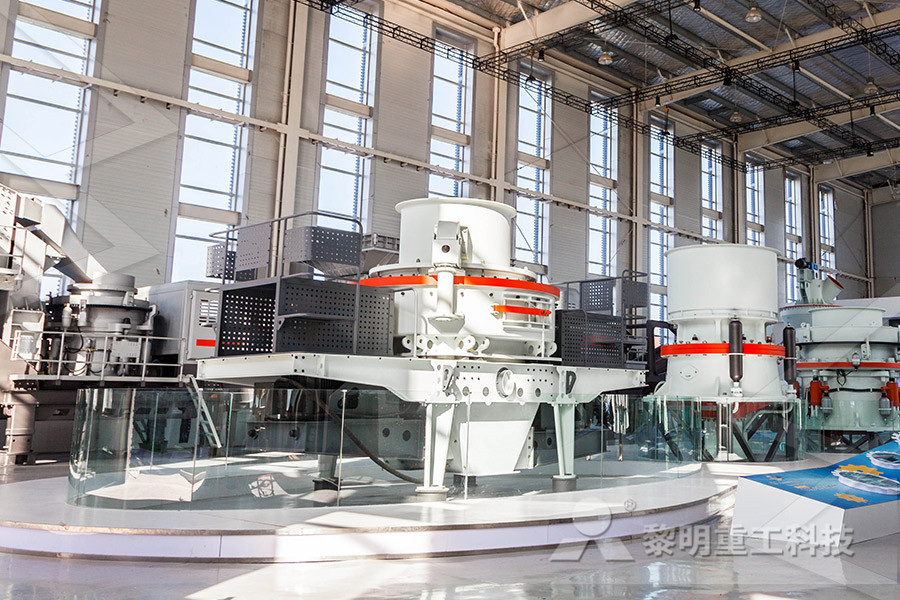

Diagram Of Gold Mining Processing Gold mining was first carried out in alluvial areas Processing system is also very simple to do that is by panning using a tray, which then developed with gold mining wave table, and followed by gravity separation Alluvial gold washing plant: Screen Trommel, Vibrating Sluice box, Rotary Scrubber, Concentrators We have more than 25 years experience, and the machines are sold to all over the world Our engineers can go to your local mining site for leading the processing plant installation and train your staffsGold Ore Processing Plant Manufacturer – Gold Aspiring gold producer Classic Minerals (ASX: CLZ) is another step closer to mining at Kat Gap after successfully commissioning its whollyowned Gekko processing plant Classic revealed the plant had been assembled and commissioned at the Classic Minerals a step closer to gold mining with

Electrowinning For Gold Mining Basic Processing Of

Diagram Of Gold Mining Processing Specimens of Gold Ore Minerals The first commercial plant in the United States is Balbach and Sons Refining and Smelting Company in Newark, New Jersey in 1883 Electrowinning is applied to a variety of chemical solutions that are found in large mining Gold bulls were disappointed that the price did not break through the $2,000/oz ceiling; nevertheless the current stable price run has helped to maintain a strong interest in gold projects Gold processing Gold processing 101 Mining Magazine The most well known carboninpulp plant remains the prototype Homestake plant in Lead, South Dakota Operating since 1973, this facility treats 2130 tonnes of ore per day averaging 27 g gold per tonne Homestake has also operated small silver Gold CIL CIP Gold Leaching Process Explained CCD

DoubleRefractory Carbonaceous Sulfidic Gold Ores

This ore has lower TCM content (058%); however, a larger portion of the gold is present as surface gold This is just a small illustration of the variability of ore components and gold carriers, key factors on selecting the processing method for a given ore Download : Gold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designsGold Processing Plant Prominer (Shanghai) Mining A slurry of ground ore, water and a weak cyanide solution is fed into large steel leach tanks where the gold and silver are dissolved Following this leaching process the slurry passes through six adsorption tanks containing carbon granules which adsorb the gold and silver This process removes 93% of the gold and 70% of the silverThe Mining Process – Waihi Gold

Gold processing Mining and concentrating Britannica

2 天前 Gold processing Gold processing Mining and concentrating: The nature of the ore deposit determines the mining and mineral processing techniques applied Oxide ore deposits are frequently of such low grade (eg, 3 to 10 parts per million) that extensive mineral processing cannot economically be justified In this case they are merely shattered by explosives and then piled into heaps for Gold processing, preparation of the ore for use in various products For thousands of years the word gold has connoted something of beauty or value These images are derived from two properties of gold, its colour and its chemical stabilityThe colour of gold is due to the electronic structure of the gold atom, which absorbs electromagnetic radiation with wavelengths less than 5600 angstroms Gold processing Britannica Aspiring gold producer Classic Minerals (ASX: CLZ) is another step closer to mining at Kat Gap after successfully commissioning its whollyowned Gekko processing plant Classic revealed the plant had been assembled and commissioned at the company’s testing Classic Minerals a step closer to gold mining with

Processing, smelting and refining gold World Gold

When gold dissolution is complete, the goldbearing solution is separated from the solids With ores of higher gold content (greater than 20 grams of gold per tonne of ore), cyanidation is accomplished by vat leaching, which involves holding a slurry of ore Gold mining in South Africa South Africa is a world leader in the gold mining industry We have been doing gold mining for more than a century and our mines are the deepest in the world Until 2010 we were the leading producer of gold in the world Gold is a lustrous, precious metal which has a very high conductivity QUESTIONS:Extracting ores Mining of mineral resources Siyavula Ridgeway, Ridgeway Mining Company Fairfield, SC Gold ore Jamestown, Sonora Mining Corp Tuolumne, CA Gold ore Paradise Peak, FMC Gold Company Nye, NV Gold ore Rabbit Creek, Rabbit Creek Mining, Inc Humboldt, NV Gold ore Barney's Canyon, Kennecott Corp Salt Lake City, UT Copper ore Continental, Montana Resources Silver Bow,MT Gold ore Zortman GOLD AND SILVER Records Collections

DoubleRefractory Carbonaceous Sulfidic Gold Ores

This ore has lower TCM content (058%); however, a larger portion of the gold is present as surface gold This is just a small illustration of the variability of ore components and gold carriers, key factors on selecting the processing method for a given ore Download : The flow diagram below shows how the percentage of copper increases as the ore is refined, first physically by froth flotation, then chemically by smelting and finally electrolytic refining The smelting stage gives the name pyroprocessing: processing by fire (Courtesy of Xstrata) The smelter for sulfide ores produces sulfur dioxide gasMining and Extraction: Oxide Ores processes for 2 天前 Gold processing Gold processing Mining and concentrating: The nature of the ore deposit determines the mining and mineral processing techniques applied Oxide ore deposits are frequently of such low grade (eg, 3 to 10 parts per million) that extensive mineral processing cannot economically be justified In this case they are merely shattered by explosives and then piled into heaps for Gold processing Mining and concentrating Britannica

DoubleRefractory Carbonaceous Sulfidic Gold Ores

This ore has lower TCM content (058%); however, a larger portion of the gold is present as surface gold This is just a small illustration of the variability of ore components and gold carriers, key factors on selecting the processing method for a given ore Download : Gold processing, preparation of the ore for use in various products For thousands of years the word gold has connoted something of beauty or value These images are derived from two properties of gold, its colour and its chemical stabilityThe colour of gold is due to the electronic structure of the gold atom, which absorbs electromagnetic radiation with wavelengths less than 5600 angstroms Gold processing BritannicaFigure 2: Opencut/underground metallic ore mining facility process diagram Figure 2 is a generalised facility process diagram for opencut metallic ore mining In general opencut mining occurs in layers as material is excavated over a period of time The mainNPI Emission Estimation Technique Manual for Mining

9 Step Process for Discovering, Mining Refining Gold

Step #6 – Mining samples and determining processing Once mining gets underway, samples must be taken to determine the precise metallurgical qualities of the ore This is done in order to determine the appropriate processing technique Step #7 – Processing (onsite) Once ore is extracted, processing it into pure gold must be doneThe Basics of Gold Mining and Processing Placer deposits, such as streambeds where people can pan for gold, are not the typical locations used by commercial gold mining companies The process begins when geologists take ore samples to determine the best places for companies to mine Once mining engineers know where gold is located and what Gold Mining and Processing: Everything you Need to Aspiring gold producer Classic Minerals (ASX: CLZ) is another step closer to mining at Kat Gap after successfully commissioning its whollyowned Gekko processing plant Classic revealed the plant had been assembled and commissioned at the company’s testing Classic Minerals a step closer to gold mining with

Mineral Processing KCGM Super Pit

The Fimiston and Gidji Processing Plants were commissioned in 1989, with Fimiston undergoing two expansion stages to become one of the largest milling complexes in Australia The process of extracting gold from sulphide ore begins when the trucks deliver the ore from the blast site to the ROM (run of mine) pad at the Fimiston Plantthat processing of a gold ore with a resin will generate superior economic returns compared to carbon, yet the resin processes have been slow to gain acceptance by the gold mining industry The main reason for this is the generally very satisfactory performance and robust economics that can be achieved with theFLOWSHEET DEVELOPMENT FOR GOLD OREBODIESThis 1day course has been designed for engineers, geologists, mineralogists, environmental scientists, plant operators, marketers, financial advisors and those either dealing with mineral processing (extractive metallurgy) or wanting a better understanding of the principles of extractive metallurgyUnderstanding Mineral Processing for non