beneficiation process iron ore

2020-04-25T01:04:40+00:00

Iron Ore Beneficiation Process 911 Metallurgist

By beneficiation is meant all methods of removing impurities, and raising the iron content to a point where it can be sold in open market, the principal impurities being silica and moisture The general processes to which low grade iron ores are amenable The following summarizes some common iron ore beneficiation processes according to the different properties of the ore: First,Strong magnetic iron ore 1Single magnetite The composition of iron ore of a single magnetite type is simple, and the proportion of iron minerals is very largeIron ore beneficiation technology and process,gravity and Weakly magnetic iron ore containing polymetallic They are mainly hydrothermal and sedimentary hematite or siderite containing phosphorus or sulfide This kind of ore usually uses gravity separation, flotation, high intensity magnetic separation or its combined process to recover iron minerals, and flotation to recover phosphorus or sulfideSummary of Iron Ore Beneficiation Process and Technology

What Is Iron Ore Beneficiation? (with pictures)

Iron ore beneficiation is a multistage process that raw iron ore undergoes to purify it prior to the process of smelting, which involves melting the ore to remove the metal content The process of iron ore beneficiation has two complementary goals and Crushing and screening is typically the first step of iron ore beneficiation processes In most ores, including iron ore, valuable minerals are usually intergrown with gangue minerals, so the minerals need to be separated in order to be liberated This screening is an essential step prior to their separation into ore product and waste rockOre Beneficiation an overview ScienceDirect Topics These techniques are used in various combinations for the beneficiation of iron ores For beneficiation of a particular iron ore the emphasis is usually to develop a cost effective flow sheet incorporating necessary crushing, grinding, screening and beneficiating techniques Beneficiation of Iron Ores – IspatGuru

Low grade Iron Ore Beneficiation and the Process of

Iron ore is normally beneficiated utilizing the principles applied in separation of the materials by the gravity, floatation, and magnetic methods Enrichment of ores utilizing the gravity concentration method is one of the oldest and most economic techniques The iron ore is an important raw material for steel production enterprises, the natural ore (iron ore) iron elected after crushing, grinding, magnetic separation, flotation these reelection proIron Ore Beneficiation Test Resultsahhli4007的博客CSDN博客 Your iron ore beneficiation solutions Reliable, expert delivery Helping to deliver your project vision, we provide core services from basic analysis through to complete metallurgically balanced flowsheets suitable for process engineering and detailed plant design Concept and Feasibility We develop tailored solutions for beneficiating iron ore toYour iron ore beneficiation solutions Mineral Technologies

Iron Ore Beneficiation Process 911 Metallurgist

Iron Ore Beneficiation Process Post navigation Previous Next During the last ten years great strides have been made, on the Mesabi range, in the practice of beneficiating low grade iron ore material By beneficiation is meant all methods of removing impurities, and raising the iron content to a point where it can be sold in open market, the Beneficiation Process For Iron Ore Tailing iron ore tailings beneficiation and processing iron ore tailings in technological process High Recovery Sulfide Copper Processing Plant With Full Engineer SupplyAbility: 100 Set/Sets per Month copper processing plant for ore separator to the froth, or float fraction, leaving the gangue in the pulp beneficiation process for iron ore tailingMicrobially induced iron ore formation has been confirmed at Gunma iron ore mine, Japan [21] Ubiquitous microorganisms inhabiting iron ore deposits are useful in iron ore beneficiation (eg, removal of alkalis, silica, clays, phosphorous, and alumina) Because the presence of phosphorous in the iron ore promotes bacterial growth (as an energy Ore Beneficiation an overview ScienceDirect Topics

Common Iron Ore Beneficiation Methods Mining

The process used for beneficiation of iron ore of this kind of ore is the most complicated one in iron ore Recovery of weak magnetic iron ore by gravity separation, flotation or strong magnetic separation and recovery of associated components by flotationIron Ore Beneficiation Introduction Iron Ore Beneficiation increases the grade of iron whilst maximising recovery and reduces the content of ultrafine low grade slimes to maximise return on investment from the mining process prior to sale or further refining in the iron making processIron Ore Beneficiation University of Newcastle Hematite beneficiation technology 083120; 443 Views; icon 1; Hematite beneficiation technology With the rapid economic development, the iron ore resources of the concentrator are decreasing year by year, and the degree of "lean, fine and heterogeneous" of selected ore is obviously increasing, the supply conditions are becoming more and more demanding, the difficulty of sorting is Hematite beneficiation technology,processing of iron

Beneficiation of Iron Ores PHDessay

The process adopted to upgrade the Fee content of air n ore is known as iron ore benefaction (108) However, Iron ores from different sources have their own peculiar mineralogy cal characteristics and require the specific benefaction and teleological treatment Table 2 shows the concentrations of various metal ions and other water quality parameters present in process water collected from iron ore beneficiation plant followed by settling and filtration It is observed from the results that the concentration of total Fe, Cr, Pb, Mn and turbidity are found to be 11524 mg/L, 710 mg/L, 268 mg/L, 096 mg/L and 977 NTU respectivelyTreatment of iron ore beneficiation plant process Process of technical indicators: 0 044 mm accounted for 9000% 95 of Estimates of the ultimate particle size of grinding mill, quartztype oxidation of iron ore iron concentrate grade of 6000%, the recovery rate of 80 00% 95 00% the amphibole type oxidizedIron Ore Beneficiation Test Resultsahhli4007的博客CSDN博客

Dry Iron Ore Beneficiation Iron Ore Separation ST

Most of iron ore resources are composed of metamorphosed banded iron formations (BIF) in which iron is commonly found in the form of oxides, hydroxides and to a lesser extent carbonates The chemical composition of iron ores has an apparent wide range in chemical composition especially for Fe content and associated gangue minerals The process adopted to upgrade the Fee content of air n ore is known as iron ore benefaction (108) However, Iron ores from different sources have their own peculiar mineralogy cal characteristics and require the specific benefaction and teleological treatment Beneficiation of Iron Ores PHDessayBeneficiation process for oxidized iron ore United States Patent Abstract: A chlorine source is provided in a reactor in combination with a ground oxidized ore and a particulate carbonaceous reductant The amount of chlorine provided is significantly less than the stoichiometric requirements for reaction with the total iron content Beneficiation process for oxidized iron ore Alberta

Iron Ore Beneficiation Test Explaine Mining Pedia

Iron ore beneficiation methods include magnetic separation process, flotation process, gravity separation process, electric separation process, wind separation process, etc Different methods are used for different iron raw ore with different properties It is strongly recommended to choose the best method based on mineral processing results Process of technical indicators: 0 044 mm accounted for 9000% 95 of Estimates of the ultimate particle size of grinding mill, quartztype oxidation of iron ore iron concentrate grade of 6000%, the recovery rate of 80 00% 95 00% the amphibole type oxidizedIron Ore Beneficiation Test Resultsahhli4007的博客CSDN博客 Table 2 shows the concentrations of various metal ions and other water quality parameters present in process water collected from iron ore beneficiation plant followed by settling and filtration It is observed from the results that the concentration of total Fe, Cr, Pb, Mn and turbidity are found to be 11524 mg/L, 710 mg/L, 268 mg/L, 096 mg/L and 977 NTU respectivelyTreatment of iron ore beneficiation plant process

Advances in Low Grade Iron Ore Beneficiation

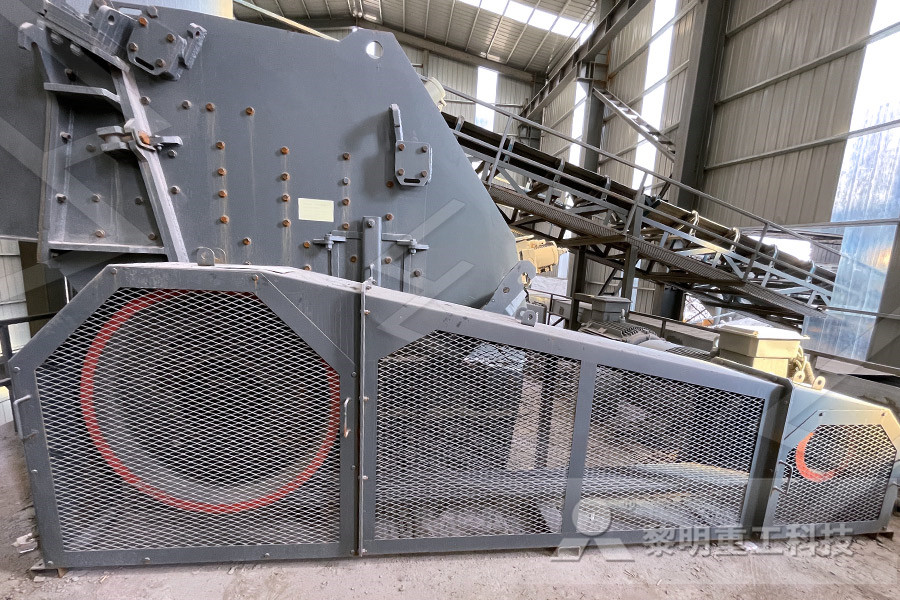

iron ore is expected to rise by more than 200 million tonne per year to meet the internal demand export This additional requirement of iron ore will need beneficiation of low grade ore/fines to get the major portion of increased demand This paper deals in brief to use of available methodologies for beneficiation of iron ore in Indian context iron ore beneficiation process Crushing Process of Iron Ore Iron ore crushing is actually the preparation process that are needed for decreasing the size of iron ores during all iron ore processing technology, which aims at make good preparation for transportation of iron ore, iron ore grinding, iron ore dissociation, and further screeningIron ore beneficiation , Iron ore beneficiation process 1 seminar on iron ore beneficiation challenges to iron steel industry presentee: k k sharma mndastur company (p) ltd kolkata, india title lean iron ore beneficiation 2 synopsis this presentation attempts to discuss the beginning of an era of lean iron ore beneficiation Lean Iron Ore Beneficiation SlideShare

A Trend ? A Necessity? Iron Ore Beneficiation

This process of increasing the grade of iron ore by exclusively processing it by different physical and chemical methods is called ‘Iron Ore Beneficiation’ Iron ore beneficiation uses the fact that the physical and chemical properties of the ore mineral and the impurities differ All this is done to ensure that the plant waste doesn’t Production Process of Iron Ore Generally, the processing of iron ore needs several processing stages, including crushing, grinding, ore beneficiation, concentrating, drying, etc The equipments for iron ore beneficiation is consisted of Jaw Crusher, Ball Mill , Classifier, Magnetic Separator, Flotation Machine, Concentrator Machine and Dryer Iron Ore,Production Process of Iron Ore,Iron Ore