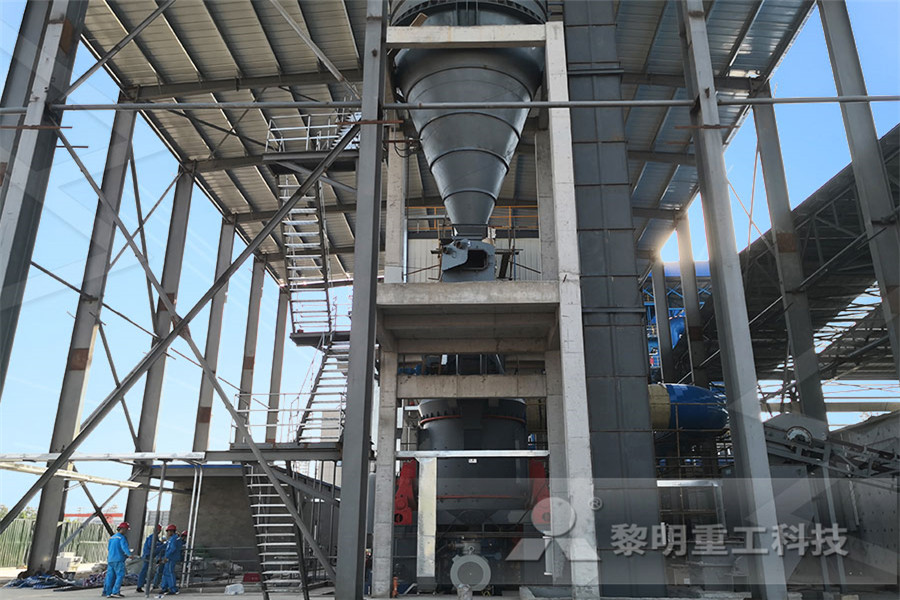

prototype for cement industry production line

2022-12-27T09:12:44+00:00

Cement factory production line production process LCDRI CN

4 In the calculation of the production loss of the complete cement production line and clinker production line, the production loss of coal should be calculated at 20%, and the production loss of other materials should be calculated at 05% The production loss of all materials in the cement grinding station shall be calculated at 05% JY, XJ, ZG, SD, YN and other cement production lines have been used in China for this new type of preheater, and the overall application is fine All cement production lines basically meet or exceed the design targets, among which JY 5500T /d cement production line exceeds more than a quarter of the designed outputCyclone preheater design for 5500 ton cement production line European cement industry –CEMCAP status 1 Technology for a better society 2 CO 2 emissions from cement production CaCO 3 > CaO + CO 2 CaCO 3, SiO 2, Al 2O 3, Fe 2O 3 a cement kiln prototype burner" TCCS‐9 poster by Francisco Carrasco Technology for a better society 12the ground for CCS in the cement industry –CEMCAP status

Tianjin Cement Industry Design and Re Institute Co

Cement industry mass utilize carbide slag technology and kiln inlet precalcining technology with combustible raw materials has applications for invention patents, and successfully put into reliable production Alborg new dry process white cement production line which general contracting and provided all the technologies by our company, is the Wet process cement production flow chart cement manufacturing process flow chart pdf,cement flow chart equipment used in the making of portland cement production process 187 learn more production of concrete by wet process pany is a manufacturer and exporter of the crushers, serving the crushing aggregate industry for 20 yearsCement Industry Process Flow Chart Pdf one of the key factors driving the cement industry in the future, largely because of how production efficiency can be increased through the timely, optimal use of resources Modelbased strategies could not be used extensively in the past for online computation of process targets This was due to the inherent complexity of industrialNew levels of performance for the cement industry

New cement technologies

The cement industry worldwide is facing growing challenges in the context of saving material and energy resources as well as reducing its CO 2 emissions The International Energy Agency highlighted in its 'Road Map for the Cement Industry' that the main levers for the cement producers are the use of alternative materials, be it as fuel or raw material and in addition the reduction of the extent that production has been increased some ten times that of the 60 foot kiln Grinding machinery has been improved to about the same ,extent The result is a ve~ marked effect on the operation of cement plants, on account of the difference in production per unit of maehine:q Page 4Problems in the cement industry Scholars' Mine, We offer enterprise level software systems for managing the entire cement manufacturing support mechanism, including equipment, maintenance, logistics, production and personnel, as well as enterprise mission systems This results in improvement in key ABB cement manufacturing operations software ABB

What does it cost to prototype a bag or clothing line

This person charges 100000 for a prototype regardless of the amount of information I provided, or the simplicity of the bag He requires a prototype to be made in his shop before any production, even if I provide a fully produced perfect copy, with pattern For production JY, XJ, ZG, SD, YN and other cement production lines have been used in China for this new type of preheater, and the overall application is fine All cement production lines basically meet or exceed the design targets, among which JY 5500T /d cement production line exceeds more than a quarter of the designed outputCyclone preheater design for 5500 ton cement Furthermore, cement production is also a major CO 2 emissions source Fig 5 shows an overview of the key production processes in cement production The importance and necessity of energy benchmarking in the cement industry is well recognized , , , Download : Download fullsize image; Fig 5 Overview of cement production processAnalysis and practices of energy benchmarking for

ExtrusionBased Additive Manufacturing of Concrete

manufacturing of concrete occurs when “printable” cementbased material is extruded through nozzles made of di erent sizes to form a layered structure [1], as presented clearly in Figure1 J Compos Sci 2019, 3, x 2 of 20 These techniques are suitable for the production However, the chemistry of cement clinker production has an added CO 2 element as well as that resulting from burning fossil fuels and that is the natural liberation of CO 2 from the raw materials used in clinker production The cement industry has been in the forefront of the development of alternative fuels, usually derived from waste sources Coal utilisation in the cement and concrete industries Portland cement is a core ingredient in traditional concrete and the cement industry accounts for about 8% of global carbon dioxide emissions So making biocement – a cement that captures carbon instead of releasing carbon – is a huge deal and Biomason is doing that with microorganisms to grow cement materialsCan Bacteria, Biocement, Biomason save the concrete

Production Flow Control for Industrie 40 ARC Advisory

The Production Flow Control Prototype In the prototype shown, a manufacturing line of several production units is placed around an “endless”, closed conveyer belt The production modules are conventional with traditional automation and cannot “converse” with each otherThe prototype home described here is based on insulated tiltup wall and ceiling panels In size, scale, and design, the home is modest Its design almost has a southwest feel to it, but it’s easy to imagine how its appearance could be adapted to a wide variety of architectural styles, from traditional to contemporaryTiltUp Concrete Cement role in case of a castinsitu reinforced cement concrete and brick building Thus, water efficiency at the production stage is required in the first case while the second category demands concerns and actions at the consumption stage This building industry is known to be a major consumer of water resource, which in many cases, is the Assessment of water resource consumption in building

Industry 40: The Future of Productivity and Growth in

Many of the nine advances in technology that form the foundation for Industry 40 are already used in manufacturing, but with Industry 40, they will transform production: isolated, optimized cells will come together as a fully integrated, automated, and optimized production flow, leading to greater efficiencies and changing traditional Buy building material online: Your onestop destination for all your construction and building material requirement online Construction and building materials procurement, which accounts for 6570% of the total cost of a construction project, suffers from challenges like high lead time, lack of process transparency leading to leakages, inefficient price discovery etc Keeping this in mind Buy Construction Building Materials Online From The continuous production line for the new prototype rolled product comprises a variety of machines, equipment and automated systems, including unwinders, dry cement powder handling systems, a main process section that forms the cement filled web, coating machines, web handling machines and rewindersConcrete Canvas chooses KEB drives, controllers and

New levels of performance for the cement industry

one of the key factors driving the cement industry in the future, largely because of how production efficiency can be increased through the timely, optimal use of resources Modelbased strategies could not be used extensively in the past for online computation of process targets This was due to the inherent complexity of industrial 2 capture in the European cement industry CEMCAP framework echno ngs ty Retrofitability: cement plants differ in construction, raw material, fuel etc Eg the capture technology suitable for Norcem in the Norwegian fullscale project is not suitable for all other cement plants Capture technologies in CEMCAP: • Oxyfuel capture • Chilled Preparing the ground for CCS in the European cement This finishing line is the fifth of its kind and part of an overall concept which also includes the production process of the cement boards All machines of this production line for construction boards were developed and manufactured by MHFBuilding materials industry MHF Maschinen und

How to speed up the solidification of cement crafts

3 Choose a cement model with a fast setting speed Cement crafts production process: 1 Make a model with the mesh, that is, the "prototype"; 2 Pour potassium soapy water on it as a release agent; 3 Use a mixed white cementChina cement handicrafts Company slurry to pour on the prototype For larger models, a sheath can be placed on the outer Many of the nine advances in technology that form the foundation for Industry 40 are already used in manufacturing, but with Industry 40, they will transform production: isolated, optimized cells will come together as a fully integrated, automated, and optimized production flow, leading to greater efficiencies and changing traditional Industry 40: The Future of Productivity and Growth in نبذة عني I am a senior mechanical engineer with an experience of 15+ years of leading teams to ensure consistent operational excellence and safe reliable execution of production operations combined with reputation of driving business growth by shaping strategies, defining requirements and contributing to the goals of the companies comprising in production and project management Azzam Magboul Chief Executive Officer Cement

About – RemovAL

removing waste from alumina production BR Reuse Although numerous sporadic projects and isolated re efforts have attempted to utilize BR as it as a feedstock in other sectors (cement, iron, etc), clearcut cases of industrial utilization of BR are rare and can only be applied on a fraction of the produced BR in a refinery Manufacturing jobs can involve the mechanical, physical, or chemical transformation of materials to create these new products Manufacturing plants and factories need more than just people who work on a production line An efficient operation requires employees in numerous roles, including management and quality assurance Manufacturing Job Titles and DescriptionsAnalysis of production safety in the construction industry of china in 2018 Sustaniability SSCI 2019年8月 22 周香莲 Coupling Effect of VortexInduced Vibration of a Submarine Pipeline and Local Scour Under Steady Current JOURNAL OF OFFSHORE SCI 23上海交通大学土木工程系