manganese mining process ore

2021-04-03T10:04:02+00:00

Manganese Mining Process Manganese Mining Mining

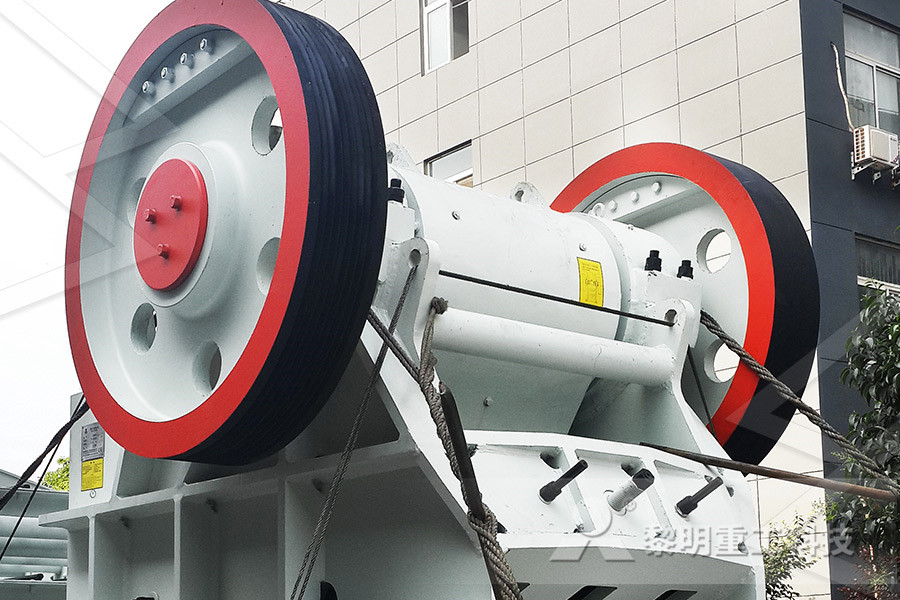

The following is a brief introduction to the ore dressing equipment of manganese ore mining process 1 Gravity separation Manganese gravity separation process flow: the raw ore enters the silo, is broken into a rough jaw crusher through a belt conveyor, The Manganese Ore Processing Plant Crushing and Sampling of Manganese Rock The flowsheet incorporates a conventional multistage crushing plant with a grizzly or screen ahead of both the primary and secondary crushers The mine run ore is dumped through a 10″ grizzly into a coarse ore Manganese Ore Processing 911 Metallurgist Most manganese mining occurs in open pits Although there are processes in place to mine manganese nodules in the ocean floor, they cannot complete with landbased mining production Once the ore is mined, it’s transferred to a processing plant for electrolytic processing or smeltingManganese Mining and Processing: Everything you Need to

process of manganese ore mining netwerkoostkampbe

Manganese Mining Process Manganese Mining Mining The following is a brief introduction to the ore dressing equipment of manganese ore mining process 1 Gravity separation Manganese gravity separation process flow: the raw ore enters the silo, is broken into a rough jaw crusher through a belt conveyor, and then enters the fine crusher for Manganese ore processing plant mining equipment for saleMay 09, 2019 manganese ore processing plantThe process flow of the manganese ore processing plant is based on the results obtained from laboratory ore dressing tests and industry testMagnetic separation process with 1 070 mm 4 600 mm tank type ore washing machine has a good effect,1 main equipment of manganese ore process plantMining Process Of Manganese JoElle Nails MoreThe manganese oxide ore is mainly adopts gravity separation method, and the ore washingheavy separationreduction roastingmagnetic separationheavy separation process flow is mostly used Of course, it is often necessary to combine two or more beneficiation methods for refractory manganese oreManganese Mining Solution Mineral Processing

Manganese processing Britannica

The mining of manganese ores is usually done in open pits Some ores are upgraded by washing, and undersized ores can be agglomerated by sintering Several processes have been developed for mining seafloor nodules, but they cannot compete Manganese are generally mined in open pits, but it has evolved from a primitive method to advanced technology process to increase the production of the manganese Even though some of the manganese are deposited on the ocean, they cannot complete with land base production When the ore is mined, it is sent for electrolytic processing or smeltingManganese Mining and Extraction Manganese Mining Manganese ore after the beneficiation process is applied in many respects in our daily lives Of annual manganese ore production, 90 percent is used in steelmaking, and the other 10 percent is used respectively in nonferrous metallurgy, chemical industry, electronics, battery, agriculture, etcThe 7 Most Useful Manganese Ore Beneficiation Methods

process of manganese ore mining

Manganese Mining Process Manganese Mining Mining The following is a brief introduction to the ore dressing equipment of manganese ore mining process 1 Gravity separation Manganese gravity separation process flow: the raw ore enters the silo, is broken into a rough jaw crusher through a belt conveyor, and then enters the fine crusher for The manganese oxide ore is mainly adopts gravity separation method, and the ore washingheavy separationreduction roastingmagnetic separationheavy separation process flow is mostly used Of course, it is often necessary to combine two or more beneficiation methods for refractory manganese oreManganese Mining Solution Mineral ProcessingThe most common type of manganese ore includes manganese oxide and manganese carbonate And the extraction of manganese mainly includes magnetic separation, gravity separation, flotation processHow to Extract the Manganese Ore? Miningpedia

Mining Process Of Manganese JoElle Nails More

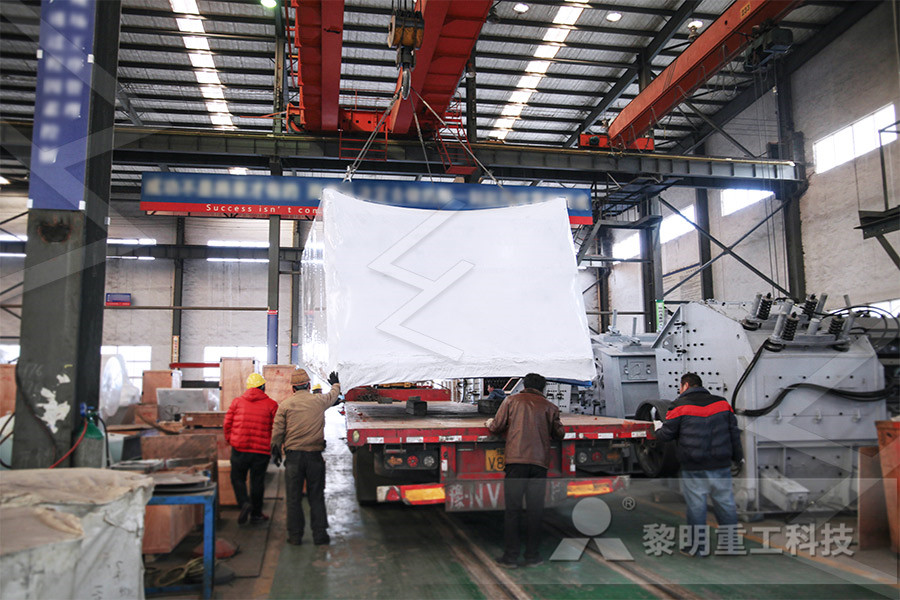

Manganese Mining Process And Plant Hippehuisvlijt Manganese ore processing plant mining equipment for saleMay 09, 2019 manganese ore processing plantThe process flow of the manganese ore processing plant is based on the results obtained from laboratory ore dressing tests and industry testMagnetic separation process with 1 070 mm 4 600 mm tank type ore washing machine has a Manganese Ore Processing Plant Mining Equipment for Sale Manganese Ore Processing Plant The process flow of the manganese ore processing plant is based on the results obtained from laboratory ore dressing tests and industry testMagnetic separation process with 1 070 mm × 4 600 mm tank type ore washing machine has a good effect, 1 Main equipment of manganese ore process plantmanganese ore mining process flocculant Manganese processing, preparation of the ore for use in various products Manganese (Mn) is a hard, silvery white metal with a melting point of 1,244 °C (2,271 °F) Ordinarily too brittle to be of structural value itself, it is an essential agent in steelmaking, in which it removes impurities suchManganese processing Britannica

Element 25 processes first ore at WA manganese play

First ore has been successfully run through ASXlisted Element 25’s new processing plant at its developing Butcherbird manganese mining and beneficiation operation in WA as part of its current commissioning program Commissioning activities have been “progressing well”, according to the company, and a saleable manganese concentrate has now been produced Manganese ore after the beneficiation process is applied in many respects in our daily lives Of annual manganese ore production, 90 percent is used in steelmaking, and the other 10 percent is used respectively in nonferrous metallurgy, chemical industry, electronics, battery, agriculture, etcThe 7 Most Useful Manganese Ore Beneficiation The ore is mined by shallow opencut mining methods and is transported by road to a nearby port Production in 2018/19 totalled 558 Mt of manganese ore The deposit comprises oolitic and pisolitic sedimentary manganese within the Cretaceous Carpentaria BasinManganese Resourcing the Territory

Comilog, the world's number 2 producer of high

The ore enrichment process is designed to increase its manganese content to just over 50% through magnetic separation Part of the enriched ore is directly sold, while another part goes through a pelletizing process in which the mineral is mixed with coke and exposed to high temperatures, which increases its manganese content to around 56% Experts believe that deep seabed mining could become a source of Manganese ore and could significantly shift from land to ocean, but with potentially severe environmental implications “In 2010 and 2011 when Lithiumion batteries became the growth driver in the battery industry, junior miners exploring and developing lithium, graphite and Manganese Mining and Processing for Investors, Explained Manganese Mining Process Manganese Mining Mining The following is a brief introduction to the ore dressing equipment of manganese ore mining process 1 Gravity separation Manganese gravity separation process flow: the raw ore enters the silo, is broken into a rough jaw crusher through a belt conveyor, and then enters the fine crusher for process of manganese ore mining netwerkoostkampbe

Mining Process Of Manganese JoElle Nails More

Manganese Mining Process And Plant Hippehuisvlijt Manganese ore processing plant mining equipment for saleMay 09, 2019 manganese ore processing plantThe process flow of the manganese ore processing plant is based on the results obtained from laboratory ore dressing tests and industry testMagnetic separation process with 1 070 mm 4 600 mm tank type ore washing machine has a Manganese processing, preparation of the ore for use in various products Manganese (Mn) is a hard, silvery white metal with a melting point of 1,244 °C (2,271 °F) Ordinarily too brittle to be of structural value itself, it is an essential agent in steelmaking, in which it removes impurities suchManganese processing BritannicaManganese Ore Processing Plant Mining Equipment for Sale Manganese Ore Processing Plant The process flow of the manganese ore processing plant is based on the results obtained from laboratory ore dressing tests and industry testMagnetic separation process with 1 070 mm × 4 600 mm tank type ore washing machine has a good effect, 1 Main equipment of manganese ore process plantmanganese ore mining process flocculant

mining process flow chart for manganese

Manganese ore processing plant mining equipment for saleMay 09, 2019 manganese ore processing plantThe process flow of the manganese ore processing plant is based on the results obtained from laboratory ore dressing tests and industry testMagnetic separation process with 1 070 mm 4 600 mm tank type ore washing machine has a Manganese ore after the beneficiation process is applied in many respects in our daily lives Of annual manganese ore production, 90 percent is used in steelmaking, and the other 10 percent is used respectively in nonferrous metallurgy, chemical industry, electronics, battery, agriculture, etcThe 7 Most Useful Manganese Ore Beneficiation Methods The ore is mined by shallow opencut mining methods and is transported by road to a nearby port Production in 2018/19 totalled 558 Mt of manganese ore The deposit comprises oolitic and pisolitic sedimentary manganese within the Cretaceous Carpentaria BasinManganese Resourcing the Territory

Iron and Manganese Ore Deposits: Mineralogy,

supplier of iron and manganese ore The global manufacture of 780 million tons of raw steel in 1999, for example, required the mining of 992 million tonnes of iron ore and approximately 18 million tonnes of manganese ore This production is from a nonrenewable reserve base The size of this reserve base is certainly finite, but estimates The ore enrichment process is designed to increase its manganese content to just over 50% through magnetic separation Part of the enriched ore is directly sold, while another part goes through a pelletizing process in which the mineral is mixed with coke and exposed to high temperatures, which increases its manganese content to around 56%Comilog, the world's number 2 producer of highgrade